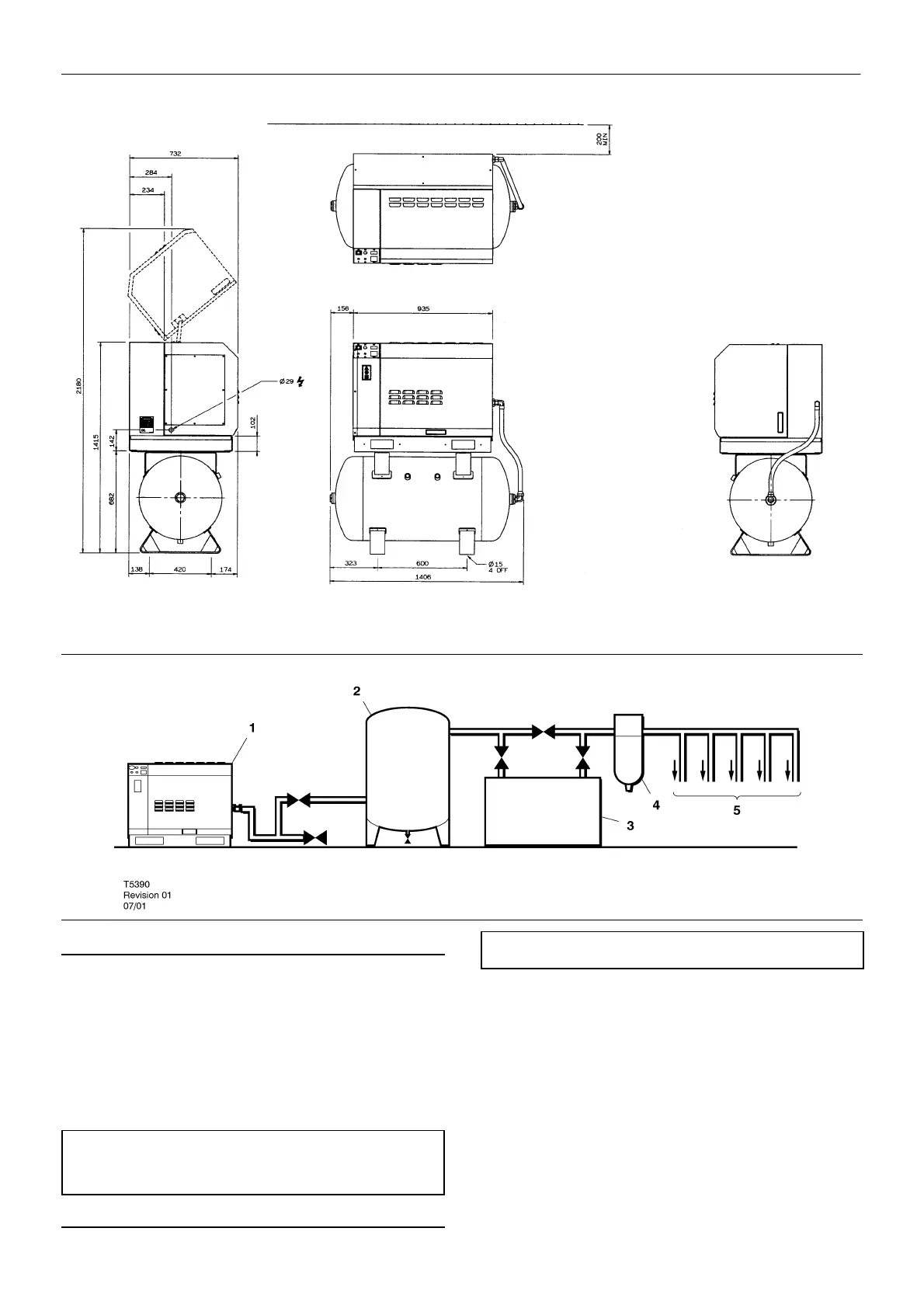

INSTALLATION / HANDLING

17

M4 M5,5 M7,5 M11

Revision 00

02/98

89210074–3

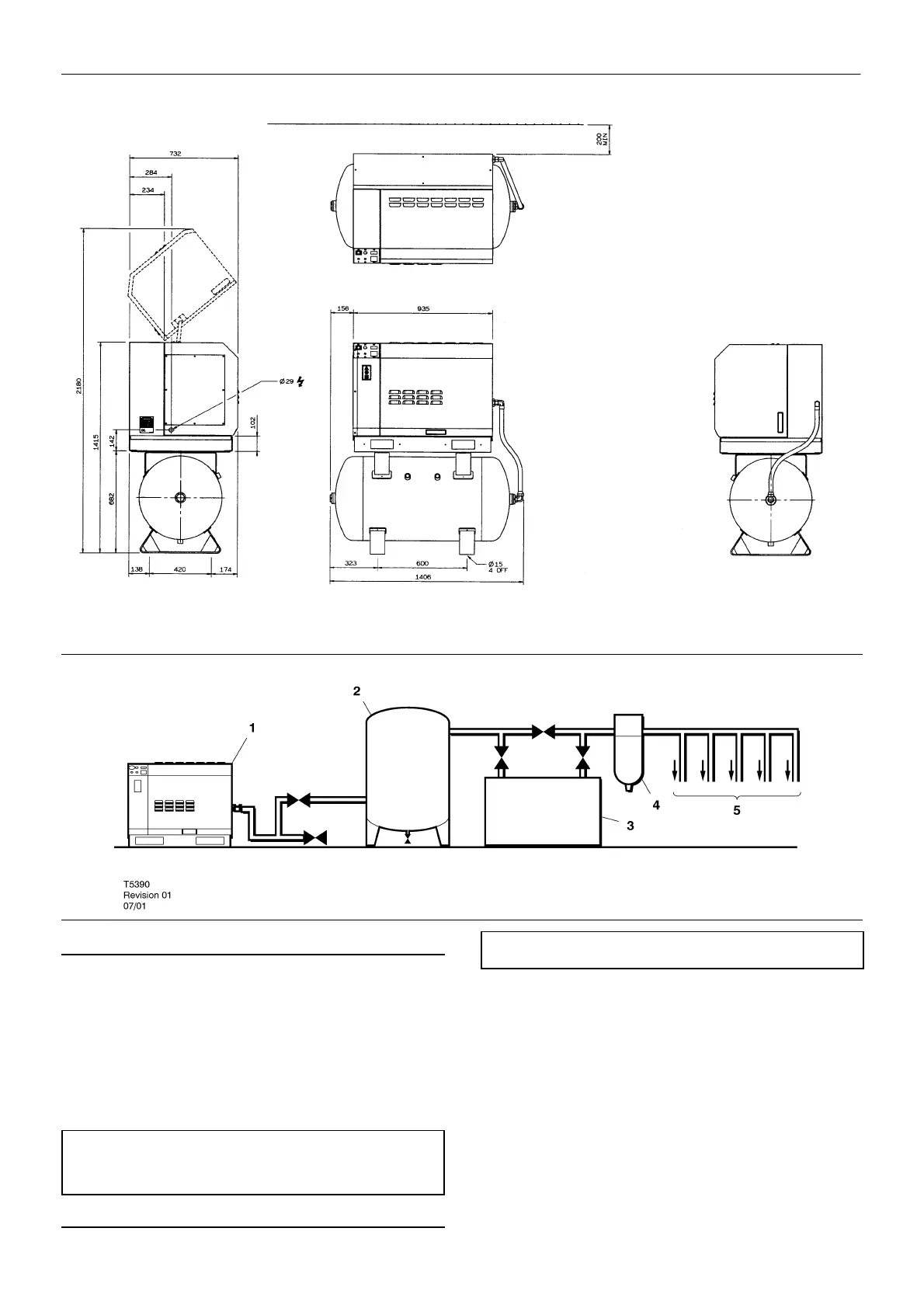

DISCHARGE PIPING

Discharge piping should be at least as large as the discharge

connection of the compressor. All piping and fittings should be suitably

rated for the discharge pressure.

It is essential when installing a new compressor [1], to review the

total air system. This is to ensure a safe and effective total system. One

item which should be considered is liquid carryover. Installation of air

dryers [3] is always good practice since properly selected and installed

they can reduce any liquid carryover to zero.

It is good practice to locate an isolation valve close to the

compressor and to install line filters [4].

NOTE

The machine is shipped with the automatic belt tension system

locked. remove the bolt which clamps the pivoted table to the main

chassis before running the compressor.

ELECTRICAL DATA

An independent electrical isolator should be installed adjacent to the

compressor.

CAUTION: Do not remove the motor table transit bolt until the electrical

connection and correct rotation have been completed.

Feeder cables should be sized by the customer/electrical

contractor to ensure that the circuit is balanced and not overloaded by

other electrical equipment. The length of wiring from a suitable

electrical feed point is critical as voltage drops may impair the

performance of the compressor. Cable sizes may vary considerably

so the mains terminals will accept up to 16mm

2

cable.

Feeder cable connections to studs L1–L2–L3 on isolator should be

tight and clean.

The applied voltage must be compatible with the motor and

compressor data plate ratings.

The control circuit transformer has different voltage tappings.

Ensure that these are set for the specific applied voltage prior to

starting.

Loading...

Loading...