MAINTENANCE

20

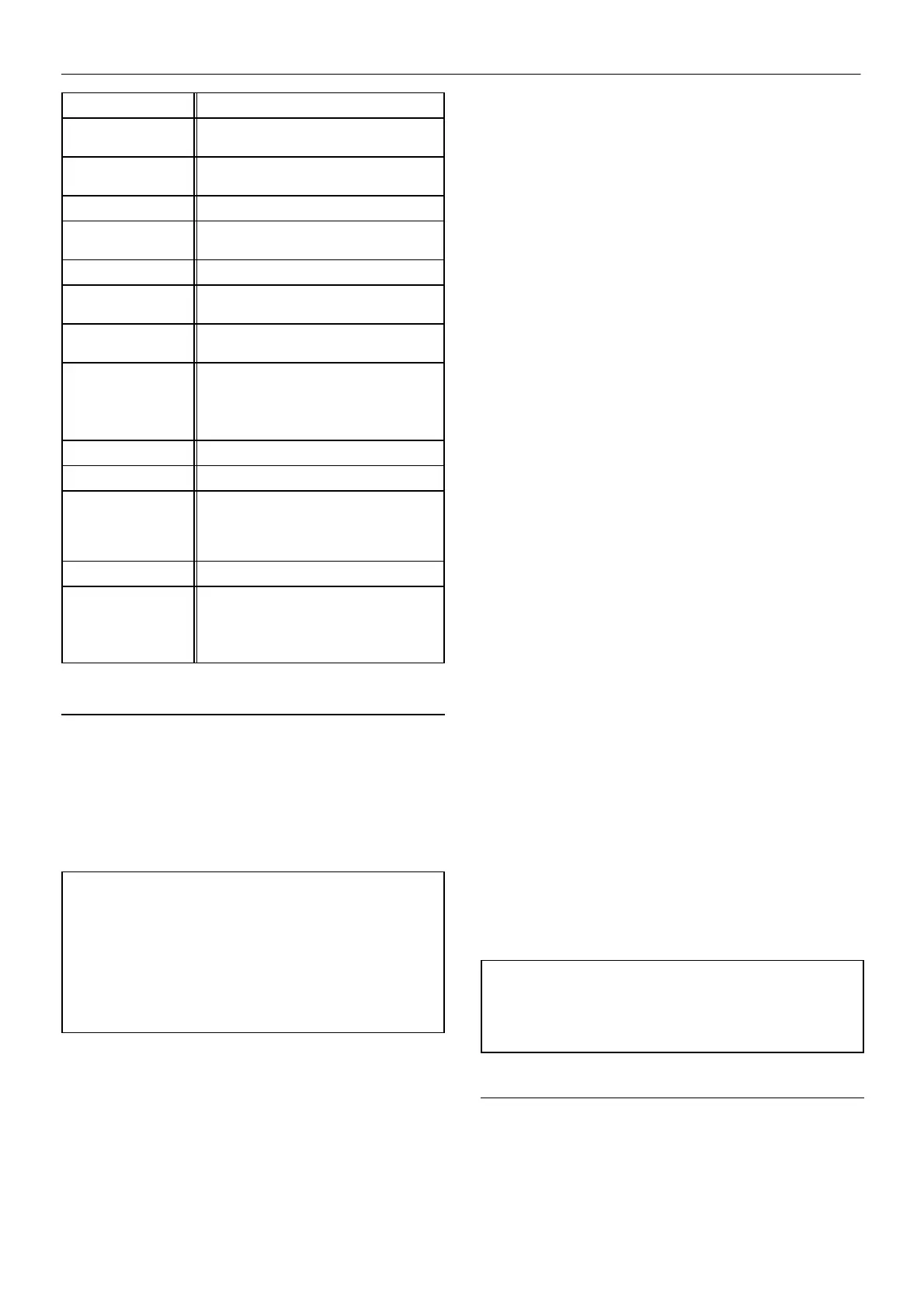

M4 M5,5 M7,5 M11

PERIOD MAINTENANCE

Daily

Check the coolant level and replenish if

necessary.

Each week

Check that the safety valve easing gear

moves freely.

First 150 hours Change the coolant filter.

Each 3 months

Check all hoses for signs of deterioration,

cracks, hardening etc.

Each 2000 hours Change the coolant filter.

2000 hours / 6

months

Check the operation of the high

temperature protection switch.

1 year

Remove the safety valve from the

compressor, inspect and re–calibrate.

1 year/1000 hours or

as defined by local

or national

legislation.

Separator tank.

Fully inspect all external surfaces, welds

and fittings. Report any excessive

corrosion, mechanical or impact damage,

leakage or other deterioration.

1 year / 4000 hours Change the air filter element.

4000 hours Change the separator element.

8000 hours / 2 years Replace the ULTRA COOLANT at

whichever interval occurs first.

Also replace the separator element and

coolant filter.

Each 8000 hours Change the drive belts.

6 years/6000 hours

or as defined by

local or national

legislation.

Separator tank.

Remove the cover plate and any

necessary fittings. Clean the interior

thoroughly and inspect all internal surfaces

and welds.

ROUTINE MAINTENANCE

This section refers to the various components which require

periodic maintenance and replacement.

The SERVICE/MAINTENANCE CHART indicates the various

components’ descriptions and the intervals when maintenance has to

take place. Coolant capacities, etc., can be found in the GENERAL

INFORMATION section of this manual.

CAUTION: Before beginning any work on the compressor, open,

lock and tag the main electrical disconnect and close the isolation

valve on the compressor discharge. Vent pressure from the unit

by slowly unscrewing the coolant fill cap one turn. Unscrewing

the fill cap opens a vent hole, drilled in the cap, allowing pressure

to release to atmosphere. Do not remove the fill cap until all

pressure has vented from the unit. Also vent piping by slightly

opening the drain valve. When opening the drain valve or the

coolant fill cap, stand clear of the valve discharge and wear

appropriate eye protection.

Compressed air can be dangerous if incorrectly handled. Before

doing any work on the unit, ensure that all pressure is vented from the

system and that the machine cannot be started accidentally.

Ensure that maintenance personnel are adequately trained,

competent and have read the Maintenance Manuals.

Prior to attempting any maintenance work, ensure that:–

. all air pressure is fully discharged and isolated from the system. If

the automatic blowdown valve is used for this purpose, then allow

enough time for it to complete the operation.

. the machine cannot be started accidently or otherwise, by posting

warning signs and/or fitting appropriate anti–start devices.

. all residual electrical power sources (mains and battery) are

isolated.

Prior to opening or removing panels or covers to work inside

a machine, ensure that:–

. anyone entering the machine is aware of the reduced level of

protection and the additional hazards, including hot surfaces and

intermittently moving parts.

. the machine cannot be started accidently or otherwise, by posting

warning signs and/or fitting appropriate anti–start devices.

Prior to attempting any maintenance work on a running

machine, ensure that:–

. the work carried out is limited to only those tasks which require the

machine to run.

. the work carried out with safety protection devices disabled or

removed is limited to only those tasks which require the machine to be

running with safety protection devices disabled or removed.

. all hazards present are known (e.g. pressurised components,

electrically live components, removed panels, covers and guards,

extreme temperatures, inflow and outflow of air, intermittently moving

parts, safety valve discharge etc.).

. appropriate personal protective equipment is worn.

. loose clothing, jewellery, long hair etc. is made safe.

. warning signs indicating that Maintenance Work is in Progress are

posted in a position that can be clearly seen.

Upon completion of maintenance tasks and prior to returning

the machine into service, ensure that:–

. the machine is suitably tested.

. all guards and safety protection devices are refitted.

. all panels are replaced, canopy and doors closed.

. hazardous materials are effectively contained and disposed of.

WARNING

Do not under any circumstances open any drain valve or remove

components from the compressor without first ensuring that the

compressor is FULLY SHUT– DOWN, power isolated and all air

pressure relieved from the system.

COOLANT CHANGE PROCEDURE

The compressor features a ’no drip’ coolant drain feature which

requires no special tools and minimises the risk of coolant spillage.

It is better to drain the coolant immediately after the compressor has

been operating as the liquid will drain more easily and any contaminant

will still be in suspension.

1. Remove the cap from the drain valve located at the front of the

separator vessel.

Loading...

Loading...