Chapter 6 Troubleshooting IS620P User Manual

- 144 -

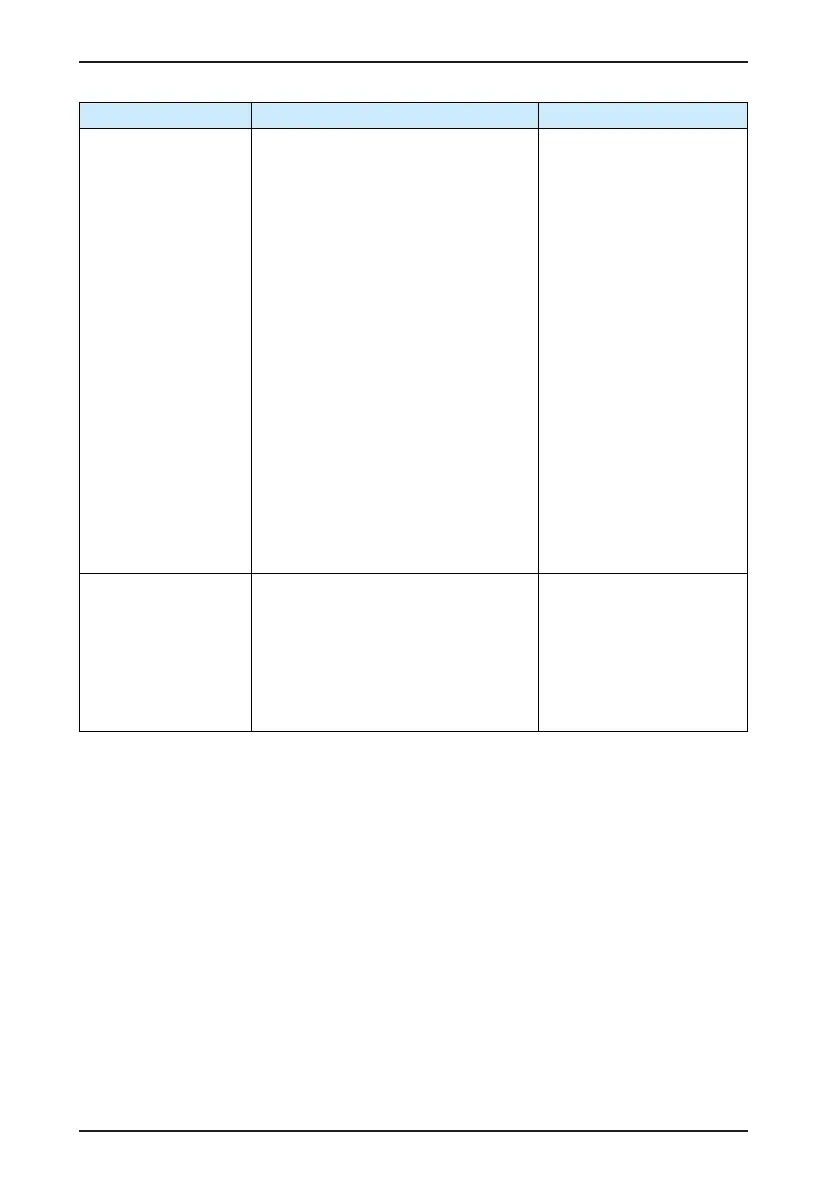

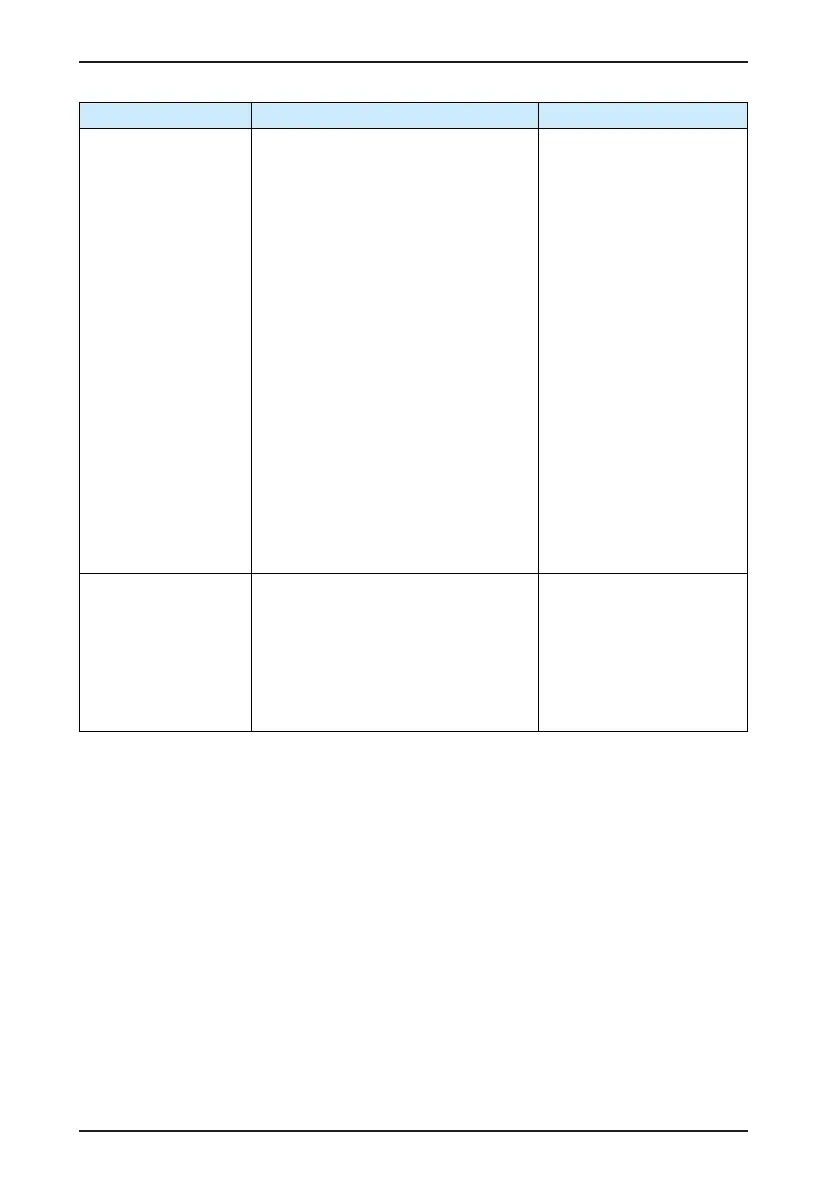

Cause Conrming Method Possible Solution

3. The Z signal of

the encoder suffers

interference

•

Check the on-site wiring condition:

Check whether there is large-sized

equipment generating interference

around the servo system or whether

there are several variable-frequency

power devices inside the cabinet.

•

Make the servo drive in the "Rdy"

state and rotate the motor shaft

counterclockwise (CCW) manually and

observer whether H0B-10 (rotation

angle/electrical angle) increases/

decreases smoothly. For the Z series

motor, turning one circle corresponds

to ve 0-360°. For the X series motor,

turning one circle corresponds to four

0-360°.

If H0B-10 changes abnormally during

rotation, it indicates that a fault occurs

on the encoder.

If no fault is reported during rotation

but the fault is report during servo

running, it is extremely possible that

interference exists.

•

Prefer to use the cable

congured by Inovance as

standard.

•

If non-standard cable

is used, check whether

the cable meets the

requirements and is STP

cable.

•

Separate the power cables

and control cables. Never

bundle the motor cables

and encoder cables

together. The grounding

terminal of the servo drive

and motor must be in good

contact.

•

Check the encoder

connector at both ends

is in good contact and

whether any pin retracts.

4. The encoder is faulty.

•

Replace it with a normal encoder

cable. If the fault no longer occurs

after replacement, it indicates that the

original encoder is damaged.

•

Place the motor on the same position,

power on the system several times and

observe the change of H0B-10. The

electrical angle must be within ±30°.

•

Replace with a normal

encoder cable.

•

If not, it indicates that the

encoder is damaged. You

need to replace the servo

motor.

Loading...

Loading...