Operation, Display and Application Examples

MD380 User Manual

- 64 -

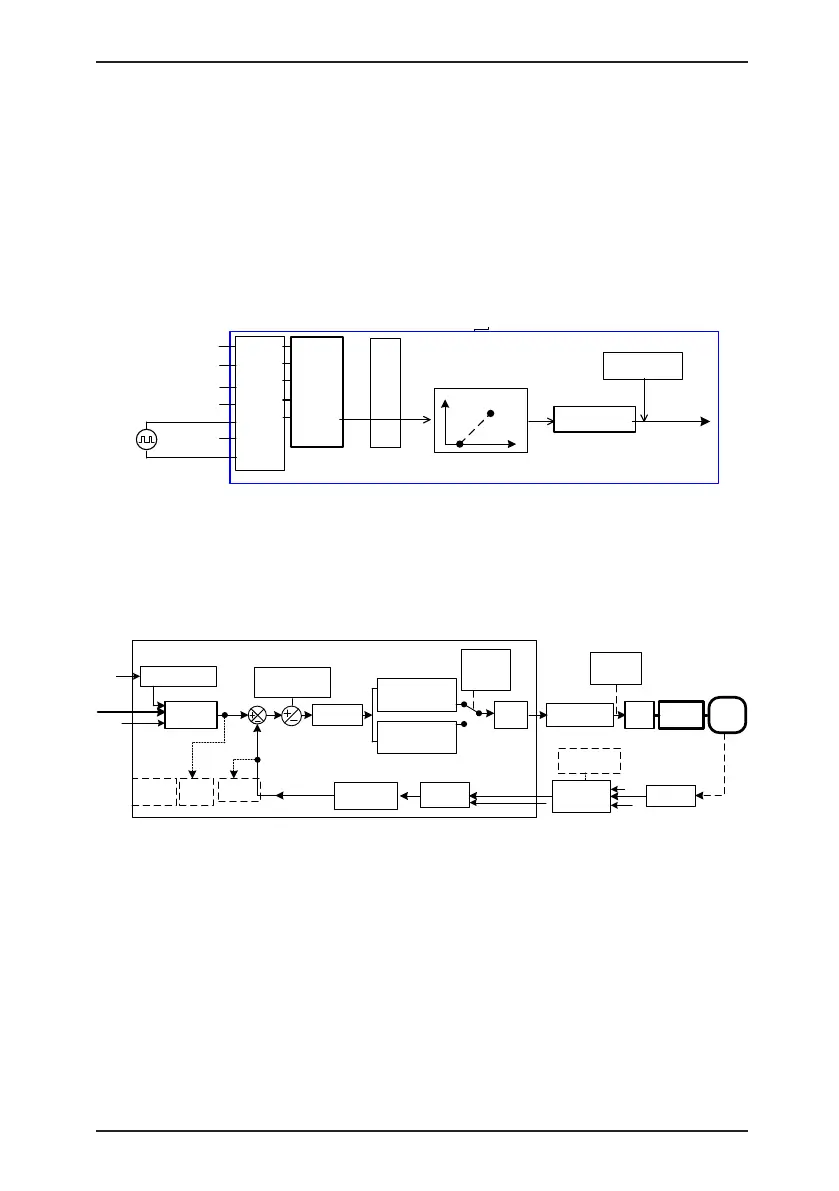

4.8.5 Pulse Setting as the Frequency Source

In many scenarios, pulse input is used as the frequency source. The specications of pulse

signals are: voltage 9–30 V, frequency 0–100 kHz.

Only DI5 can be used for pulse input. The relationship between pulse input from DI5 and

the corresponding setting is set in F4-28 to F4-31. The relationship is a two-point line, and

100% of pulse input corresponding setting corresponds to the maximum frequency of F0-10,

as shown in Figure 4-22.

Figure 4-22 Pulse setting as the frequency source

F4-00

F4-01

F4-02

F4-03

F4-04

.

.

.

.

.

30

.

F0-03 = 5

Running

frequency

Terminal

Function

code

Setting

value

DI1

DI2

DI3

DI4

DI5

.

COM

Frequency

source selection

OC output

F0-07 = 0

Pulse setting

Frequency

feature setting

F4-28 to F4-31:

Relationship between

pulse setting frequency

and running frequency

*

Only DI5 can be used for pulse input.

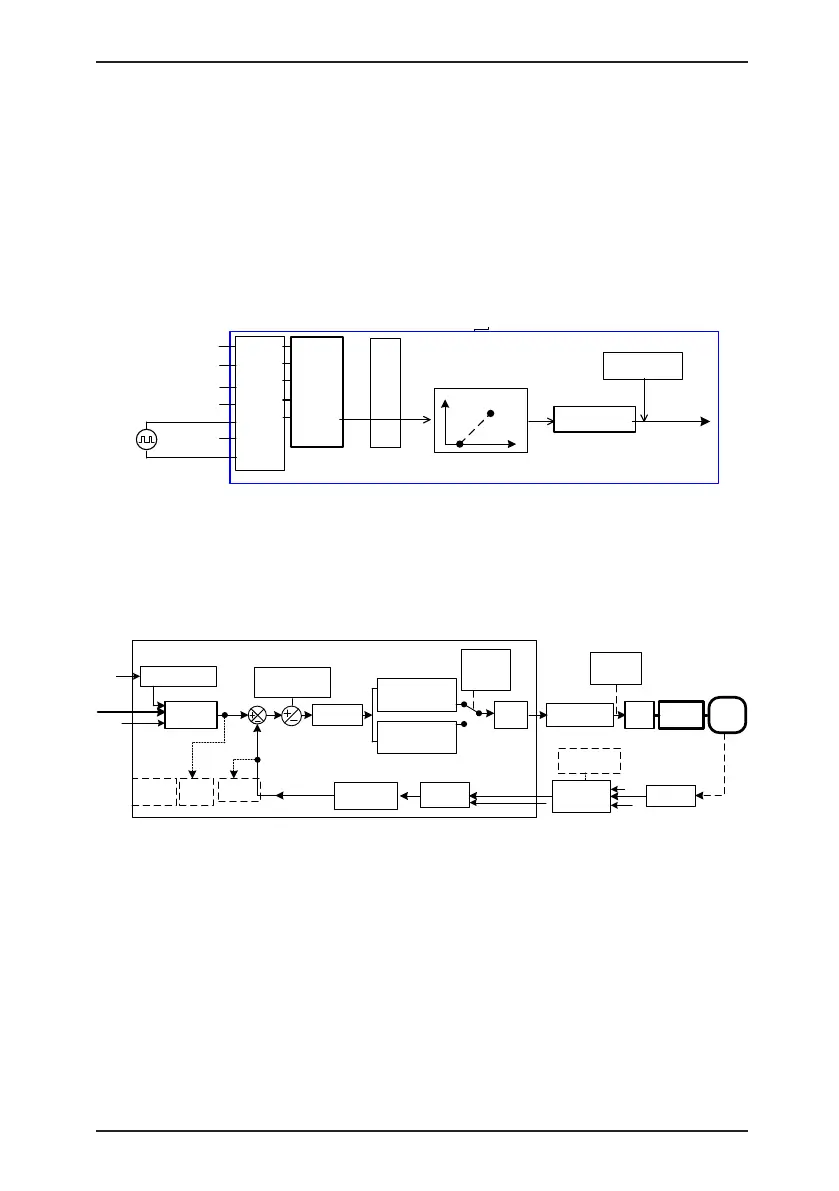

4.8.6 Frequency Closed-Loop Control

The MD380 has a built-in PID regulator. Together with the frequency sources, the PID

regulator can implement automatic adjustment of progress control, such as constant

temperature, constant pressure, and tension control.

Figure 4-23 Automatic adjustment by PID regulator

F0-07 = 0

F0-27 = 0

F0-03 = 8

Frequency

source selection

FA-00

(PID setting

source

)

Setting

target

Built-in PID

regulator

FA-01

(PID digital setting)

FA-03 (PID action

direction)

0: Forward action

1: Reverse action

FA-09

(

PID deviation

limit)

FA-04

(PID setting

feedback

range

)

PID1:

Proportional Kp

1: FA-05

Integral Ti1: FA-06

Derivative Td1: FA-07

PID2:

Proportional Kp2: FA-15

Integral Ti

2: FA-16

Derivative Td2: FA-17

FA-13

FA-23

FA-24

PWM

drive

Execution

by motor

Object

FA-18

FA-19

FA

-20

Switchover

condition

Transmitter

detection

FA-12

(PID feedback

filter time)

FA-02 (PID

feedback

source)

PID

feedback

PID output

feature

PID output

frequency

U0-15

(PID

setting )

U0-16

(PID

feedback)

PID

setting

F4-33

AI parameter

feature

preprocessing

F4-13 to F4-32

(Calibration

curve)

Physical

quantity

Electric

signal

%

%

%

When PID frequency closed-loop control is implemented, F0-03 (Main frequency source X

selection) must be set to 8 (PID). The PID-related parameters are set in group FA, as shown

in Figure 4-23.

The MD380 has two built-in equivalent PID calculating units. You can set the features,

such as adjustment speed and accuracy, for the two units separately based on the actual

conditions. Switchover between the two units can be implemented automatically or by

means of an external DI terminal.

Loading...

Loading...