PW800, Users

Rev O, January, 2008

15

2: The IZSM (initial zero setting mechanism on power up) must be within +/- 10%

of the zero obtained at calibration.

3: The push-button zero and AZSM can only operate within +/- 2% of the IZSM.

4: The over-capacity point is 103% of capacity above the IZSM.

18. The scale shows “EE-10

EE-10EE-10

EE-10”. Press the NET/GROSS and MODE keys. The scale

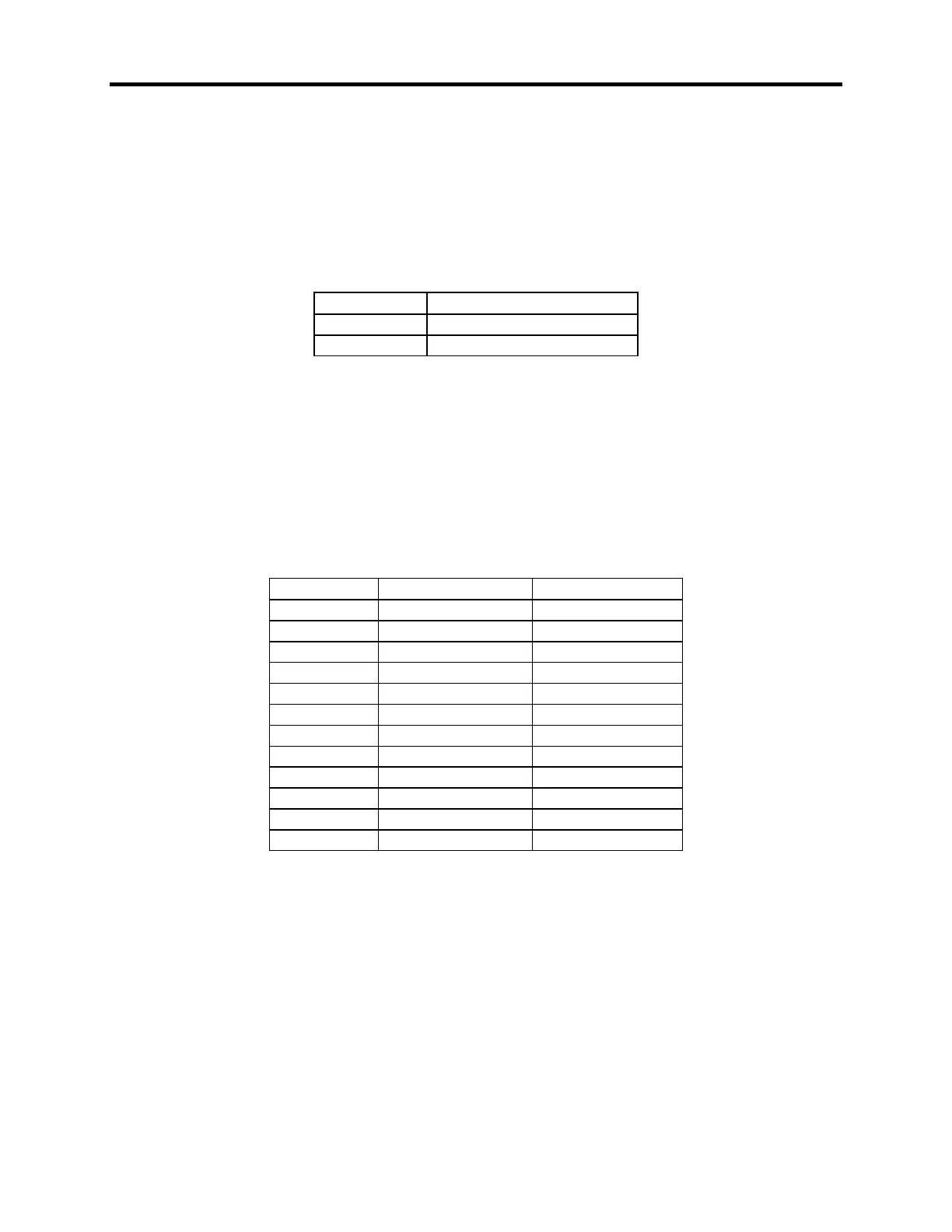

shows the current 'Initial zero range' setting. Use the following table to select the

'Initial zero range' setting:

Setting Initial zero range

0 Off

1 On

A '0' setting implies: The initial zero setting mechanism (IZSM) will work over the

entire range of the scale capacity and the over-capacity point is 103% above the

zero obtained at calibration.

A '1' setting implies: The IZSM must be within +/- 10% of the zero obtained at

calibration and the over-capacity point is 103% above the IZSM.

19. The scale shows “EE-11

EE-11EE-11

EE-11”. Press the NET/GROSS and MODE keys. The scale

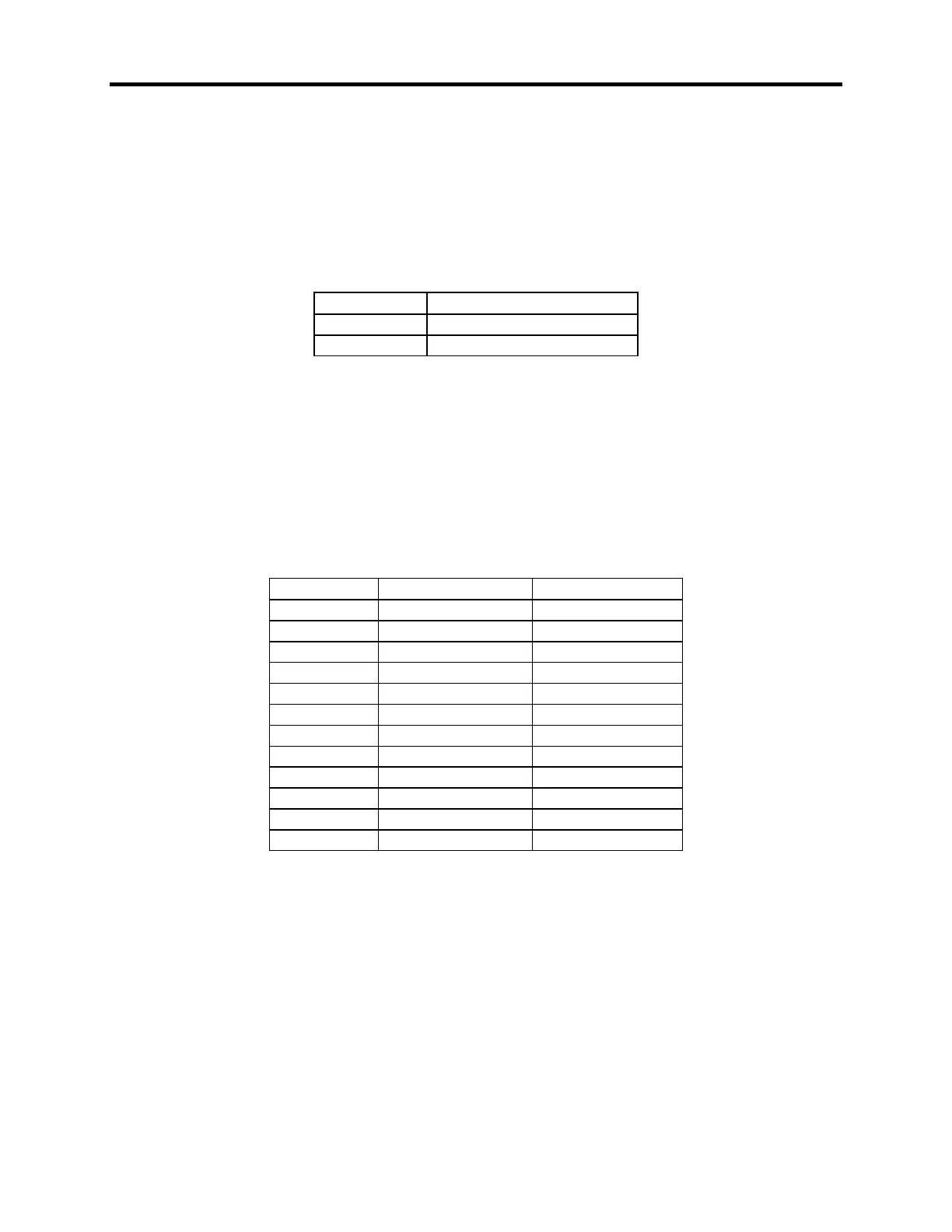

shows the current graduation selection. Use the following table to select a

graduation value.

Settings Count by in lb Count by in kg

0 100 50

1 50 20

2 20 10

3 10 5

4 5 2

5 2 1

6 1 0.5

7 0.5 0.2

8 0.2 0.1

9 0.1 0.05

10 0.05 0.02

11 0.02 0.01

20. The display shows “EE-12

EE-12EE-12

EE-12”. This parameter is reserved for future use. Press

NET/GROSS and MODE keys together twice to continue.

21. The scale shows “EE-13

EE-13EE-13

EE-13”. Press the NET/GROSS and MODE keys. The display

shows the current circuit board ID#. This is used in multi scale applications. The

circuit board ID is used for identification.

Loading...

Loading...