Version 1.00 | Optidrive CoolVert User Guide | 43www.invertekdrives.com

6

Technical Data

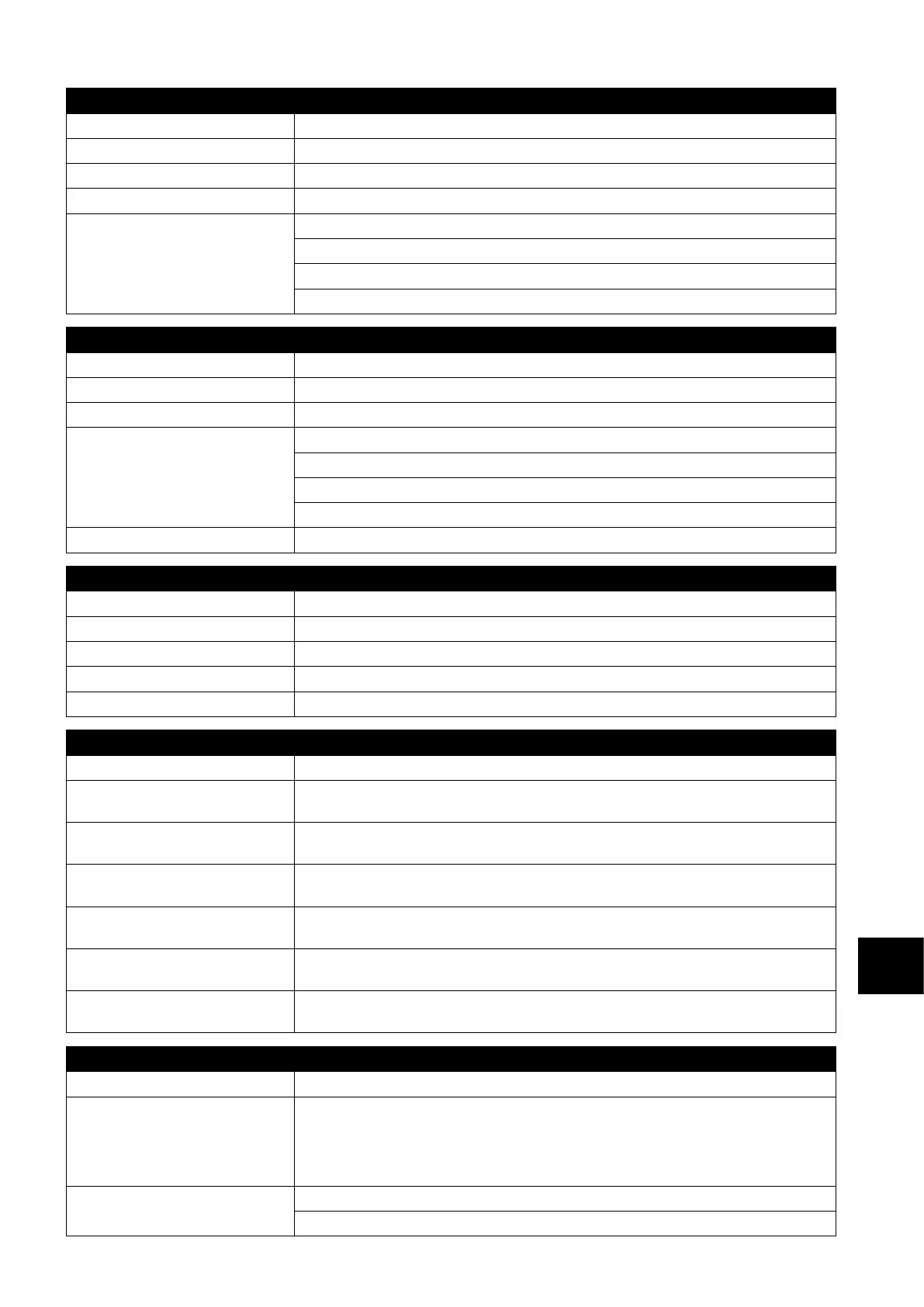

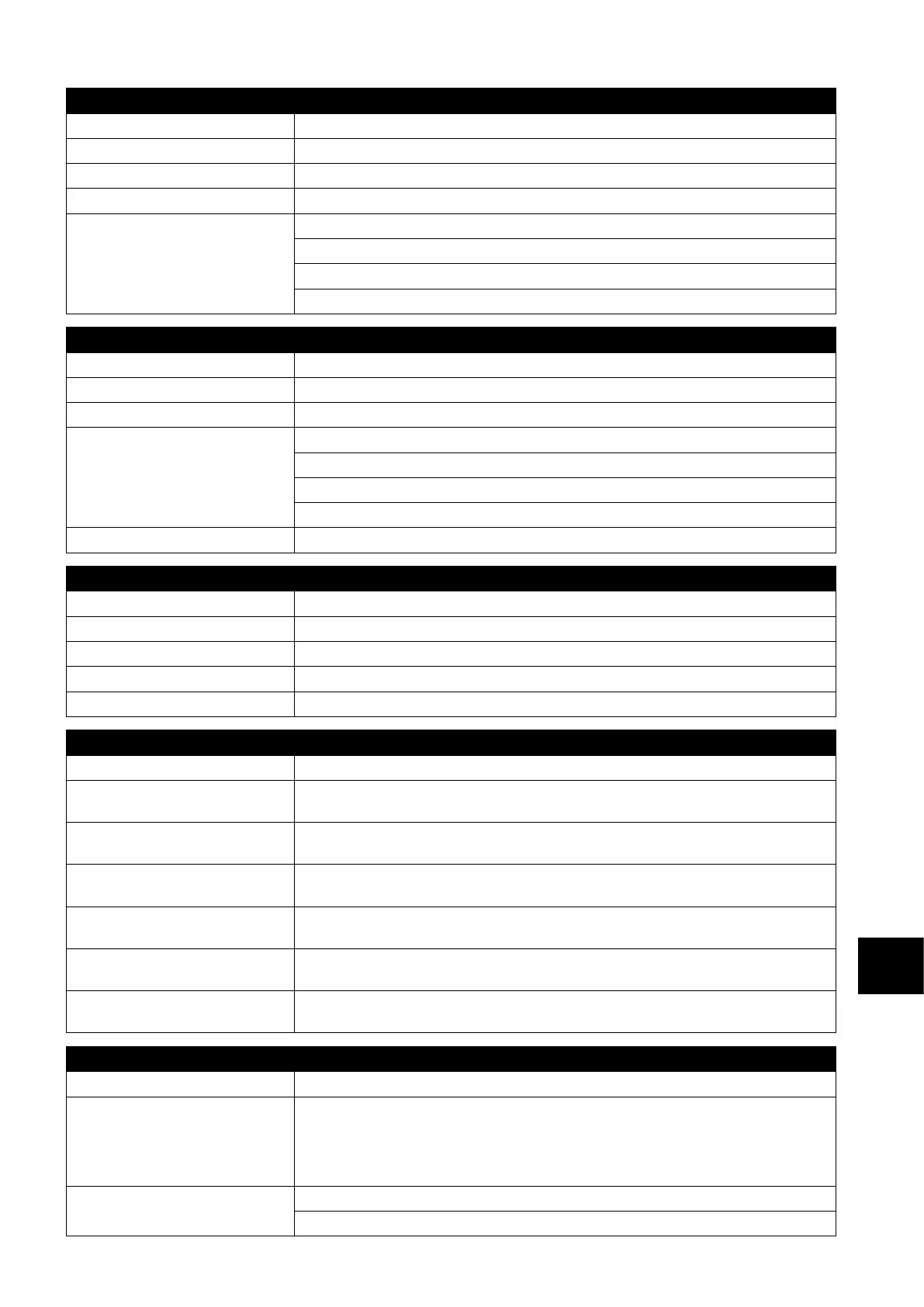

Control Specification

Output Voltage 0 - Vin

PWM Frequency 4 – 32kHz

Stop Mode Ramp to stop, Ramp to minimum speed then coast to stop, Coast to stop

Skip Frequency 2 skip frequencies, user adjustable

Control Modes Modbus RTU (RS485)

Terminal Control Digital / Analogue

Terminal Control PI mode

Master / Slave Mode

I/O Specification

Power Supply 24 Volt DC, 100mA, Short Circuit Protected

Digital Inputs 1 (24V Positive Logic)

Analogue Inputs 1 (0-10V, 0-20mA, 4-20mA, PTC)

Relay Outputs 1 (AB type)

Maximum Voltage 250VAC, 30VDC

Switching Current Capacity: 6A AC, 5A DC

Resistive Load

Safe Torque Off (STO) Independently approved STO input

Safe Torque Off (STO)

IEC 61800-5-2:2016 SIL 3

EN ISO 13849-1:2015 PL “e”

EN 61508 (Part 1 to 7): 2010 SIL 3

EN 60204-1: 2006 & A1: 2009 Cat 0

EN 62061: 2005 & A2: 2015 SIL CL 3

Application Features

PI Control Internal PI Controller.

3 - step start-up profile Start-up profile configurable with up to 3-steps to reduce the risk of oil migration and

support better charge distribution in the system.

Compressor start-up protection Several configurable built-in compressor protection features including Minimum

Compressor On Time, Minimum Compressor Off Time and Compressor Restart Delay.

Intelligent Drive Thermal

Management

Reduced-load operation of the compressor can be configured under high drive

temperatures to prevent nuisance tripping.

Intelligent Motor Thermal

Management

Reduced-load operation of the compressor can be configured under continued motor

overload to prevent nuisance tripping.

Serial Communications-Loss Fall-

Back Speed

The ability to configure the drive to run at a ‘safe’ speed in the event of a loss of serial

communication. Can prevent loss of cooling/heating.

Master Follower Configuration The ability to run a cascade of compressors with one Master regulating the operating point

in PI Control.

Maintenance & Diagnostics

Fault Memory Last 3 trips stored with time stamp

Data Logging Logging of data prior to last trip for diagnostic purposes:

Output Current

Drive Temperature

DC Bus Voltage.

Monitoring Hours Run Meter

kWH

Loading...

Loading...