Version 1.00 | Optidrive CoolVert User Guide | 23www.invertekdrives.com

4

Set-up and Operation

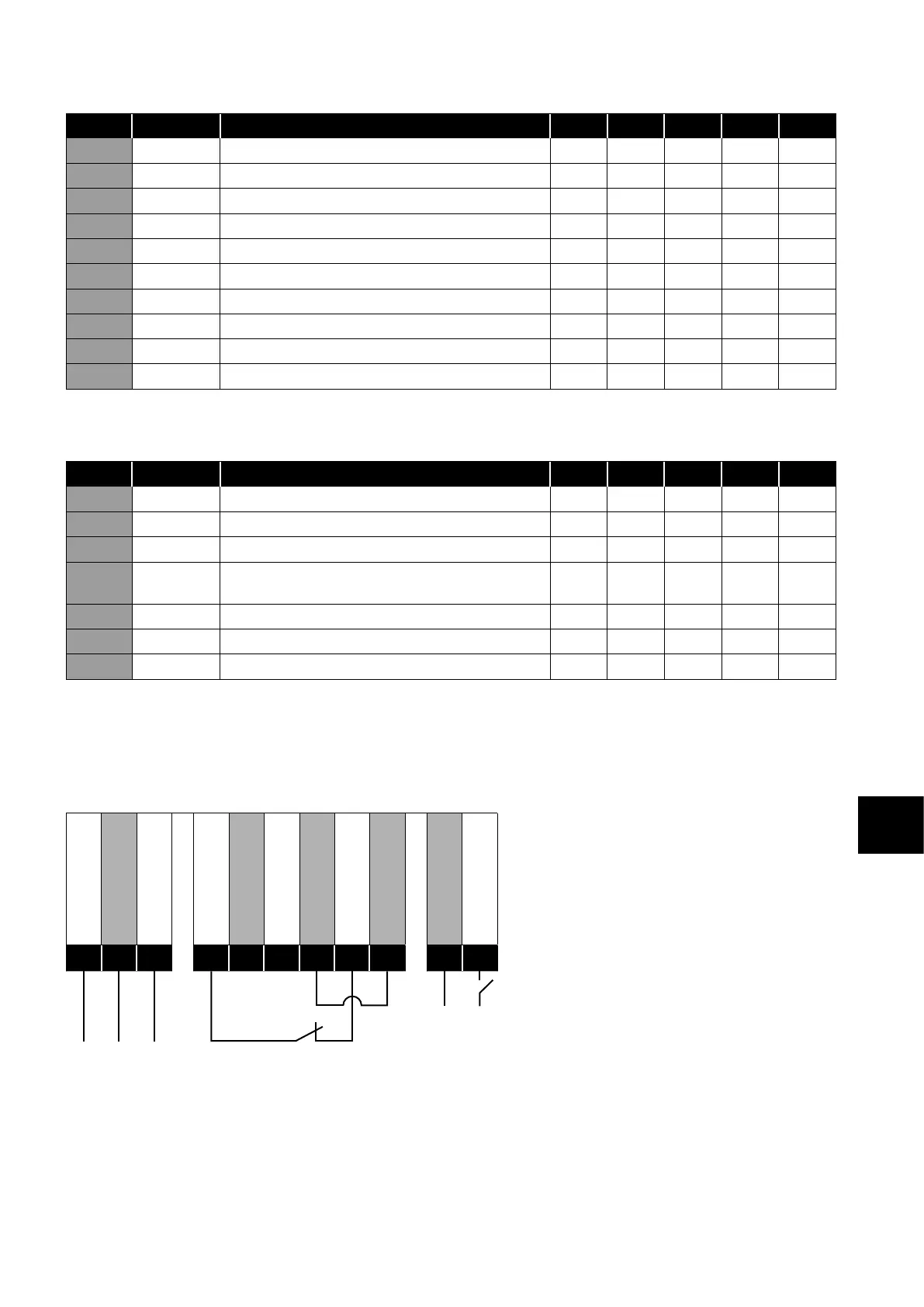

4.1.7. System Tuning

Par. Mod Add Description Def Min Max Unit R/W

5-03 503 Vector Speed Controller Proportional Gain 50 0 .1 400 % R/W

5-04 504 Vector Speed Controller Integral Time Constant 0.050 0.001 2.00 s R/W

7-01 701

Minimum Switching Frequency – Thermal Management

- - - kHz R/W

7-02 702 Auto-reset Delay 20 1 60 S R/W

7-03 703 Motor Stator Resistance (Rs) phase to phase W R/W

7-04 704 Motor Stator Inductance (Lsd) per phase mH R/W

7-05 705 Motor Stator Inductance (Lsq) per phase mH R/W

7-06 706 V/F Mode Magnetising Period - 0 5000 Ms R/W

7-07 707 Low Frequency Torque Boost Level 0.0 0.0 100 % R/W

7-08 708 Low Frequency Torque Boost, Frequency Limit 0.0 0.0 50 % R/W

The values for P7-03 through to P7-05 are gathered by the drive during the autotune process.

4.1.8. Thermal Protection

Par. Mod Add Description Def Min Max Unit R/W

5-07 507 Maximum Current Limit 110 20 150 % R/W

5-08 508 Motor Power Limit 13 0 0 13 0 % R/W

5-09 509 Motor Thermal Overload Management (Ixt) 0 0 1 - R/W

5-10 510 Drive Thermal Overload Management

(Drive Temperature Based)

0 0 1 - R/W

5-11 511 Motor Thermal Overload Retention Enable 1 0 1 - R/W

7-01 701

Minimum Switching Frequency – Thermal Management

- - - kHz R/W

7-02 702 Auto-reset Delay 20 1 60 S R/W

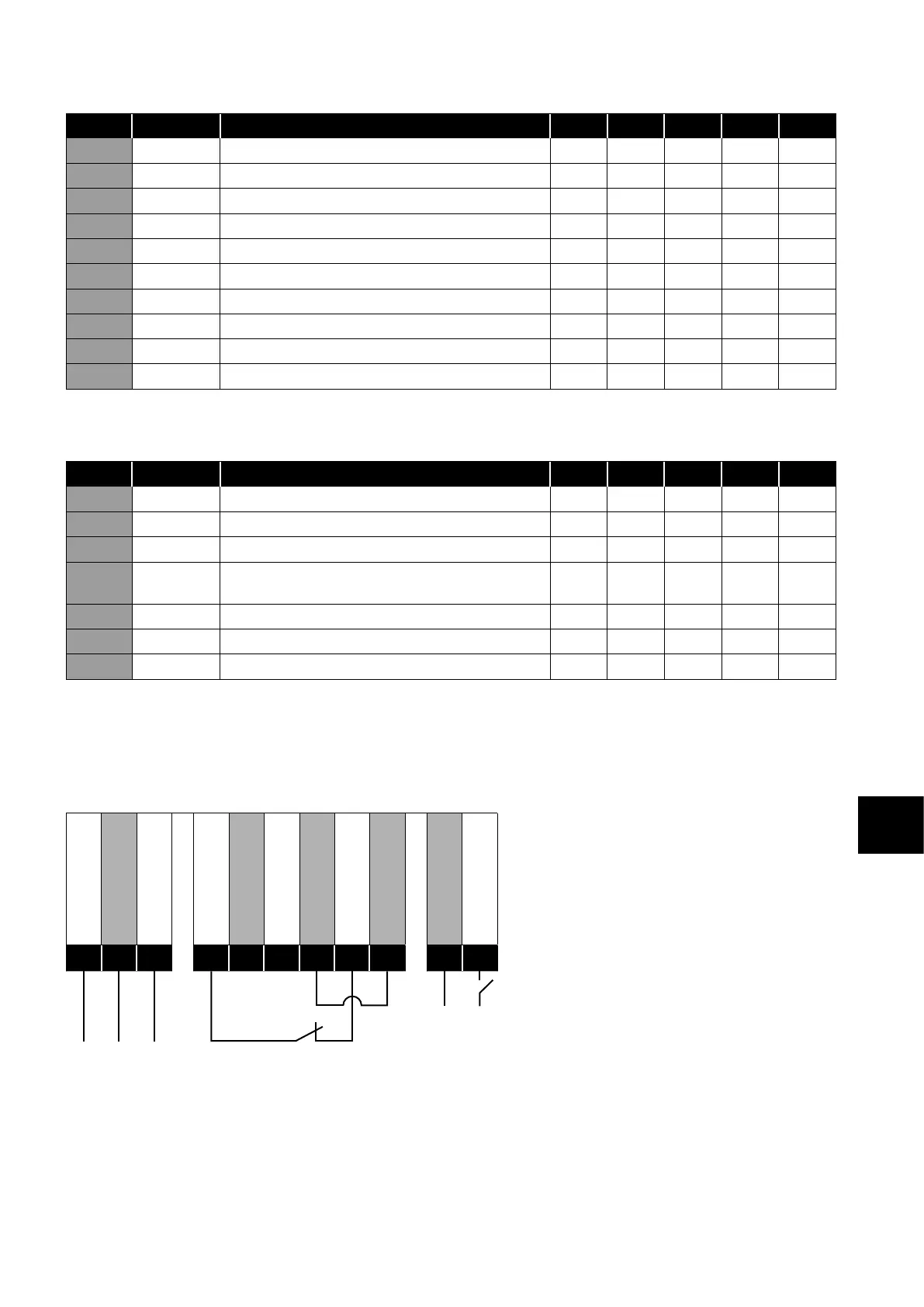

4.2. Modbus Connections

4.2.1 Minimum Control Wiring Required For Each Control Mode

See parameter 1-11 in section 4.1.6. Control Mode on page 22.

P1-11 = 0 - Modbus control

0V Common

Modbus TX/RX +

Modbus TX/RX -

+24V Output (100mA)

Digital Input 1

Analogue Input 1

0V Common

STO +

STO -

User Relay A

User Relay B

1

2

3

4

5

6

7

8

9

10

11

STO signal must be provided in order to permit running the motor. Start/Stop commands and speed reference are provided by serial

communication. In Modbus mode, the digital input and analogue input can be used as remote I/O by the controller, the relay output

can also be configured to be controlled by Modbus and used by the controller if required.

Loading...

Loading...