Goodrive300 Series VFD Basic operation instruction

178

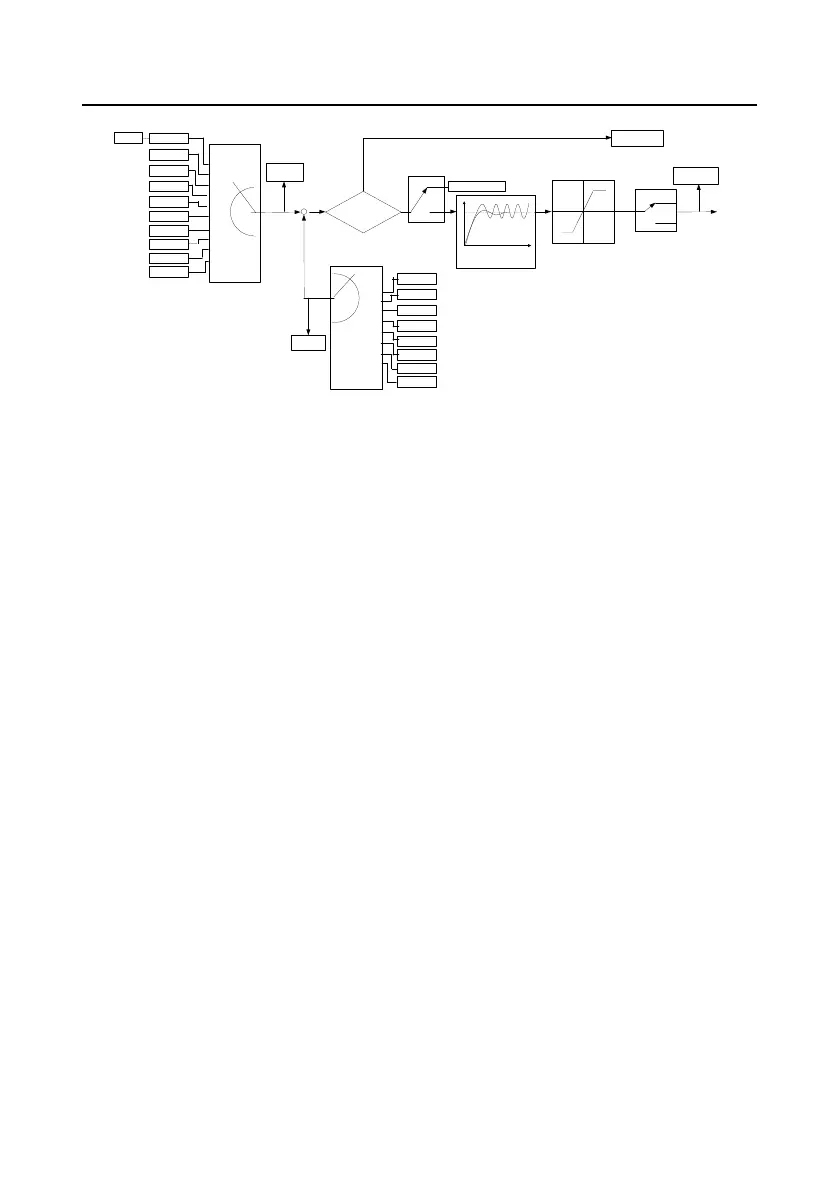

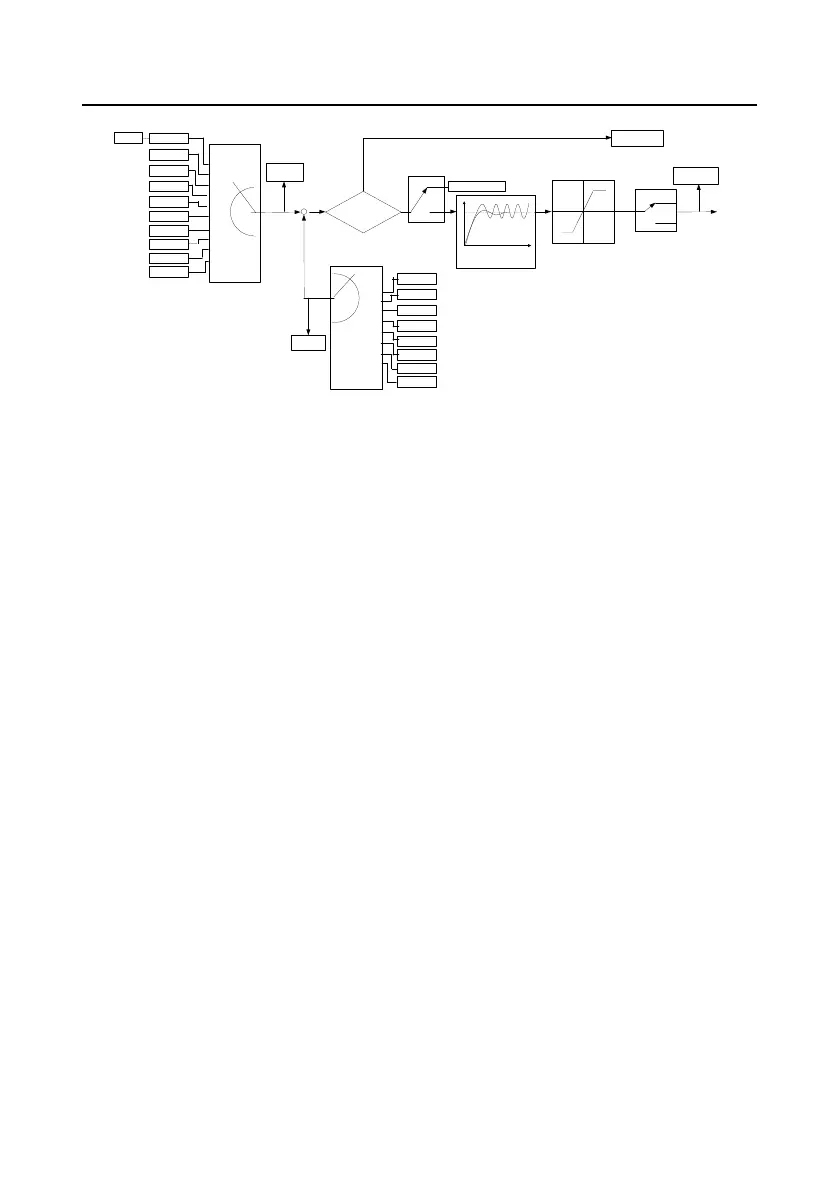

+

-

Given -feedback<P09.08?

P09.10

(lower limit of PID output)

P09.09

(the upper limit of PID

output )

0

1

P09.03

(the chrematistic of PID

output)

PID output

P17.00

P17.23

P09.08(PID control deviation limit)

P09.02

(PID feedback source selection)

P09.00

(PID given source selection)

P17.24

PID feedback

value

PID given value

Set frequency

0

1

2

3

4

5

6

7

8

9

Keypad

AI1

PROFIBUS

MODBUS

Multi-stage

speed

HDI

AI3

AI2

Ethernet

CAN

0

1

2

3

4

5

6

7

AI1

PROFIBUS

MODBUS

HDI

AI3

AI2

Ethernet

CAN

Y

N

PID stop

adjustment

Keypad setting PID given

Keep the current

frequency

Terminal function 25

PID control pause

Valid

Invalid

Kp P09.04(proportional gain)

Ti P09.05(integral time )

Td P09.06(differential time)

P09.01

Simple illustration of the PID control operation and adjustment:

Proportional adjustment (Kp): when there is an error between the feedback and the reference, a

proportional adjustment will be output. If the error is constant, the adjustment will be constant, too.

Proportional adjustment can respond to the feedback change quickly, but it cannot realize non-fault

control. The gain will increase with the adjustment speed, but too much gain may cause vibration. The

adjustment method is: set a long integral time and derivative time to 0 first. Secondly make the

system run by proportional adjustment and change the reference. And then watch the error of the

feedback signal and the reference. If the static error is available (for example, increasing the

reference, the feedback will be less than the reference after a stable system), continue to increase the

gain, vice versa. Repeat the action until the static error achieves a little value.

Integral time (Ti): the output adjustment will accumulate if there is an error between the feedback and

the reference. The adjustment will keep on increasing until the error disappears. If the error is existent

all the time, the integration adjustor can cancel the static error effectively. Vibration may occur as a

result of unstable system caused by repeated over-adjustment if the integration adjustor is too strong.

The features of this kind of vibration are: the fluctuating feedback signal (around the reference) and

increasing traverse range will cause vibration. Adjust the integral time parameter from a big value to a

little one to change the integral time and monitor the result until a stable system speed is available.

Derivative time (Td): when the error between the feedback and the reference, a proportional

adjustment will be output. The adjustment only depends on the direction and value of the error

change other than the error itself. The derivation adjustment controls the change of feedback signals

according to the changing trend when it fluctuates. Because the derivation may enlarge the

interference to the system, especially the frequent-changing interference, please use it carefully.

When P00.06, P00. 07=7 or P04.27=6, the running mode of the VFD is procedure PID control.

7.15.1 General steps of PID parameters setting:

a Ensure the gain P

When ensure the gain P, firstly cancel the PID integration and derivation (set Ti=0 and Td=0, see the

Loading...

Loading...