IONPURE

®

VNX CEDI Modules

Page 14 IP-MAN-VNX-1019-EN.pdf

3. VNX MODULE INSTALLATION

3.1. Preparation

Confirm that the pre-installation requirements outlined in Section 2 are met and the

system is ready for VNX Module installation.

· Remove any packaging materials and move the module to its

operating location. Use safe lifting practices when moving the module

(see Section 2.2).

· To avoid corrosion, the piping adapters and plugs must be non-metallic.

· Modules are shipped with PVC connection adapters and plugs installed.

· Optional polypropylene PP adapters and plugs are available

· If other adapter types are required, the module end must be made to the dimensions

provided in drawings C-1 through C-4 in Appendix C. This is essential to ensure

proper sealing of the adapter in the endblock.

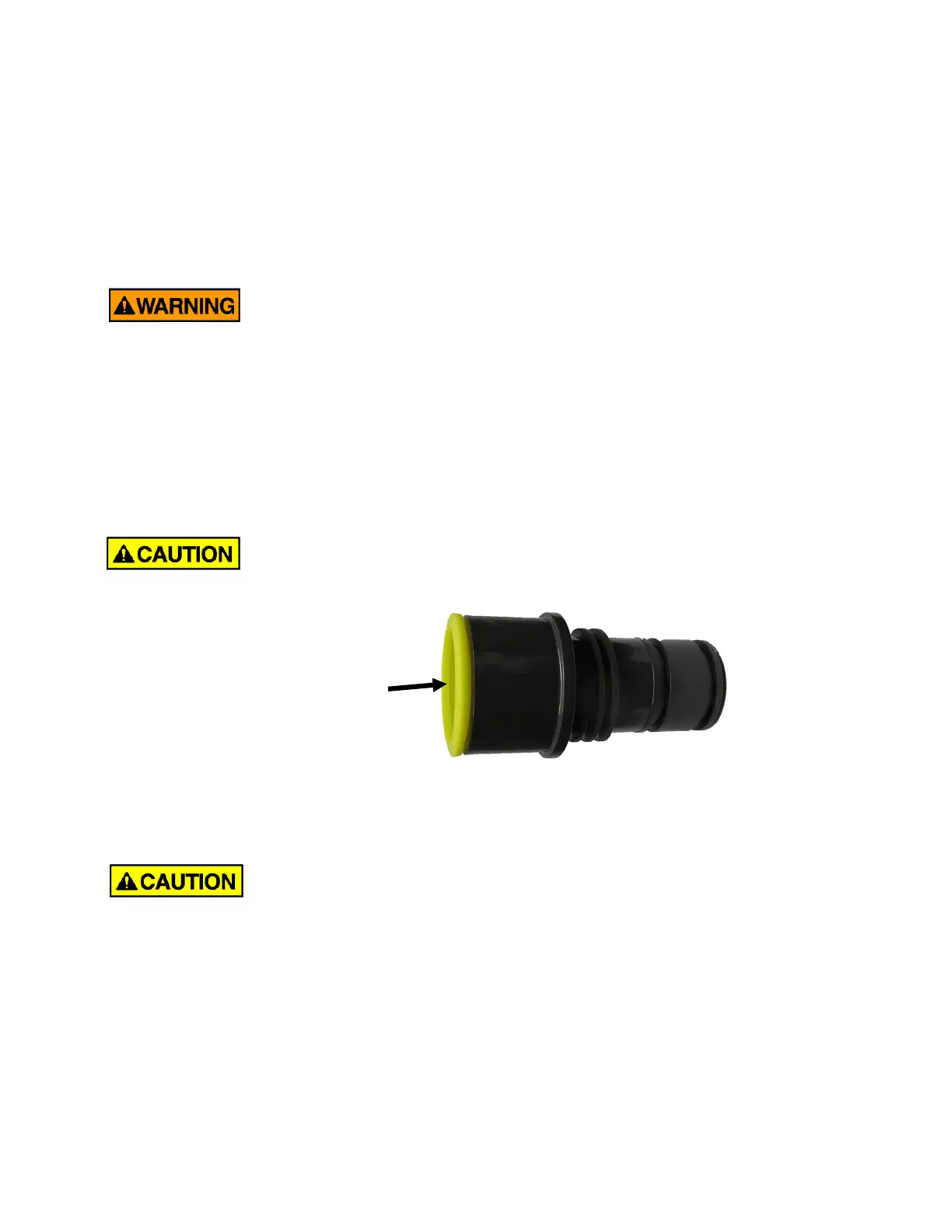

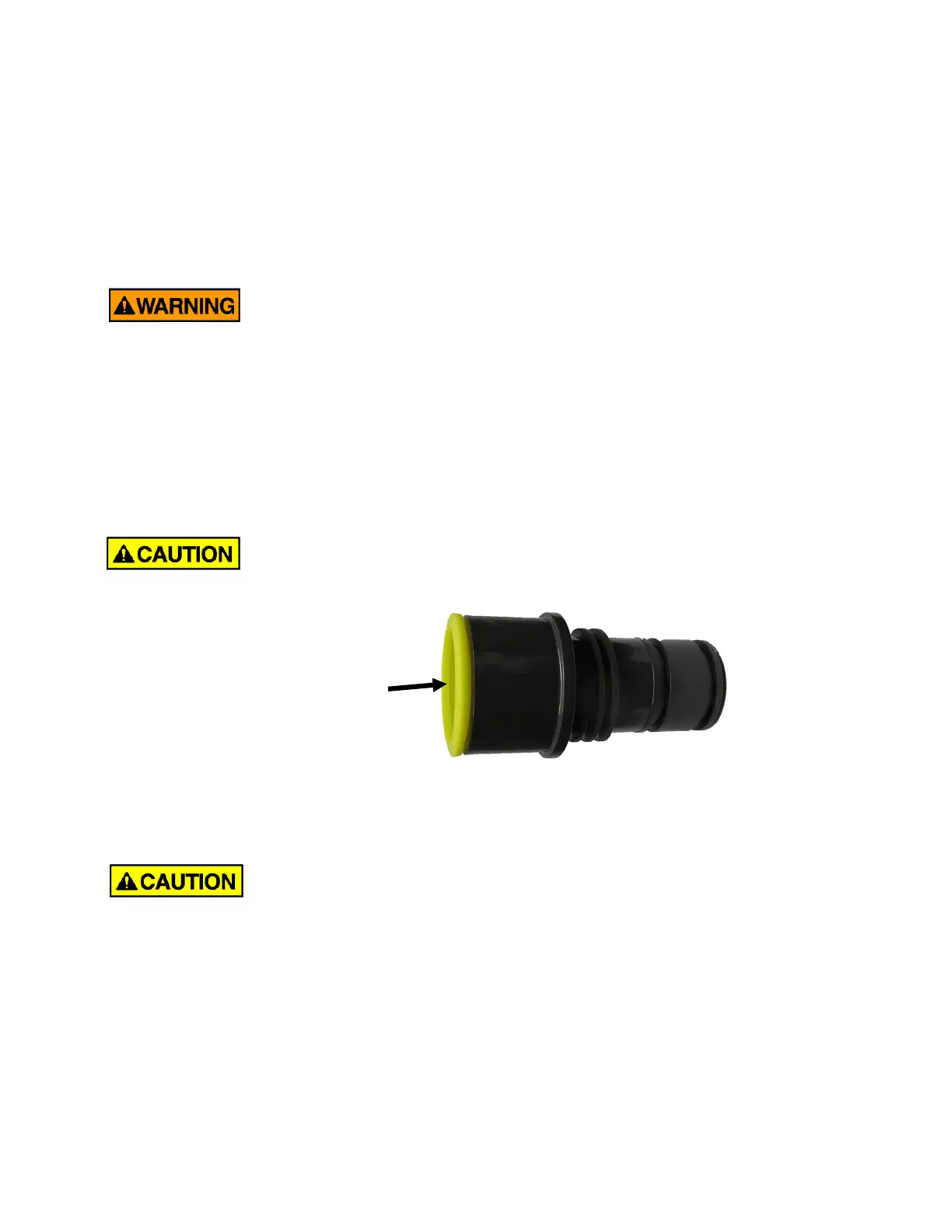

· Remove the yellow dust plugs that seal the inlet and outlet ports on

the module (see Figure 3-1). Failure to remove yellow dust plugs can

cause permanent damage to the modules.

Figure 3-1 VNX PVC adapter with yellow shipping plug

3.2. Water Connection Configuration and Fittings

· Make sure all upstream pretreatment equipment and piping have

been thoroughly flushed with particle-free water before connecting

them to the VNX Module. Flushing removes any particles left in the

piping from cutting and assembly. If particles remain, they could plug the passages inside

the VNX Module.

NOTE: Failure to properly flush the pretreatment water system of installation debris to

drain prior to flowing water to the CEDI can result in particulate fouling that may be

irreversible.

Remove this

yellow dust plug

Loading...

Loading...