IONPURE

®

VNX CEDI Modules

Page 20 IP-MAN-VNX-1019-EN.pdf

4. PREPARATION FOR STARTUP

4.1. Verify Feed Water Meets VNX Quality Requirements

Check the VNX feed water quality by running the RO system to drain and testing to make

sure the feed water quality meets all the feed water requirements given in Tables 2-3 and

2-4. Below are some of the test kits or devices that may be useful:

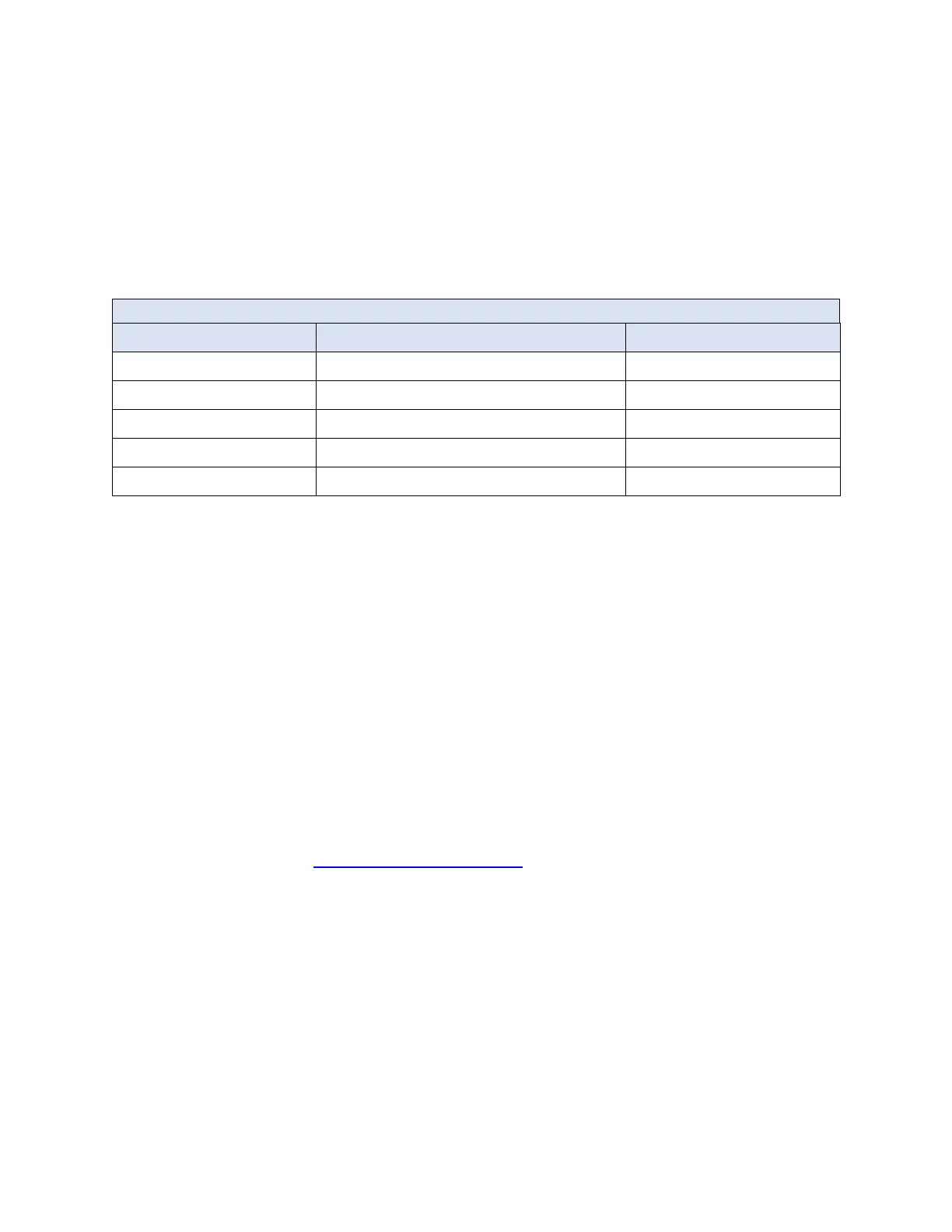

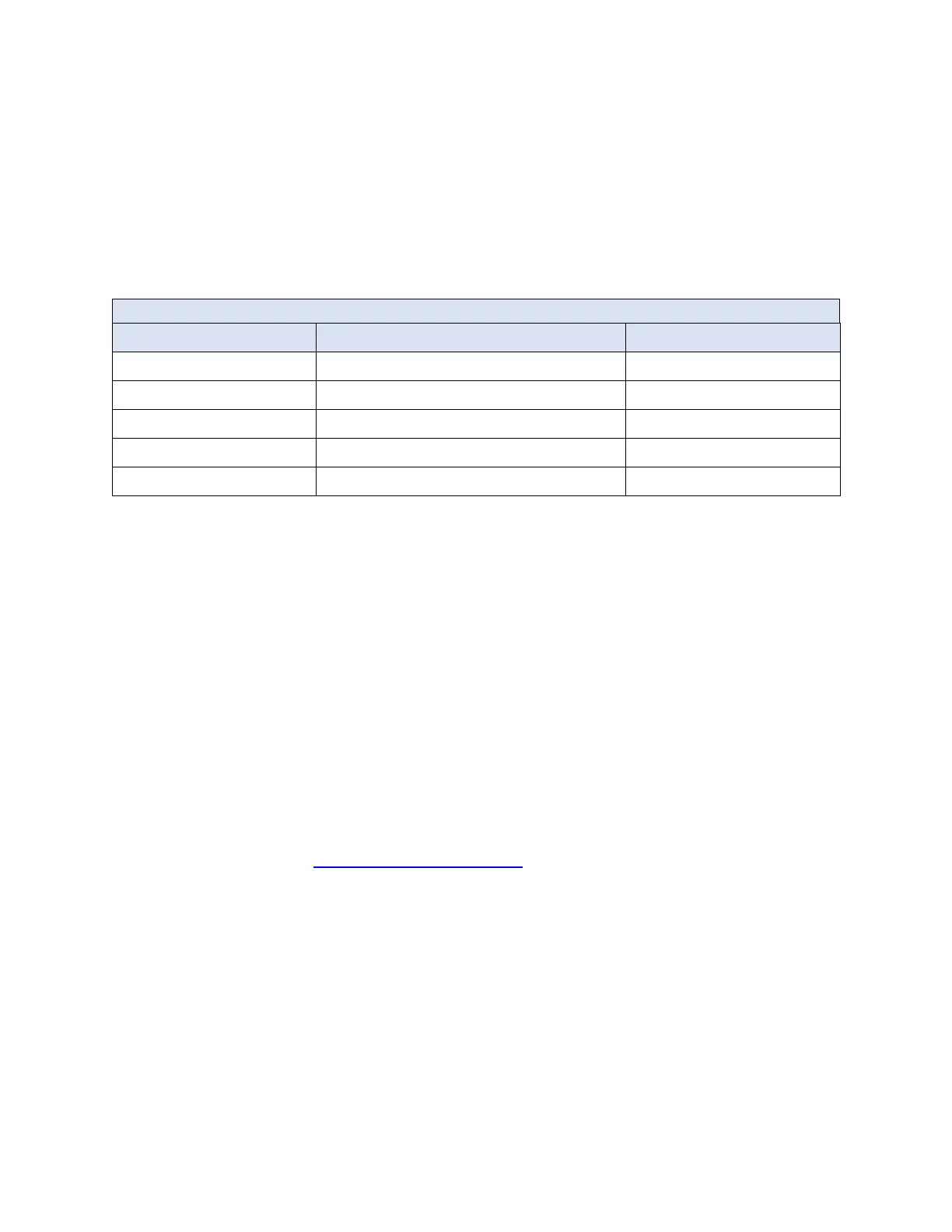

Table 4-1 Useful Equipment for Feed Water Testing

Analyte Model Minimum Increment

Conductivity Myron L Ultrameter II 4P 0.1 µS/cm

CO

2

Hach CA-23 (#143601) 1.25 mg/l

Cl

2

Hach CN-70 (#1454200) 0.02 mg/l

Hardness Hach HA-71A (#145201) 1.0 mg/l

Silica Hach SI-7 (#2255000) 0.05 ppm

4.2. Estimate DC Current Required

An important part of the startup process for the VNX module is setting the operating

current correctly for each particular application. The amount of DC current required

depends on the following site-specific conditions:

· Product flow rate per stack, number of cells per stack

· Number of stacks (electrode pairs) per module

· CEDI feed water conductivity equivalent (FCE)

· Measured feed water conductivity (may require a portable conductivity meter)

· Feed water carbon dioxide concentration (requires test kit such as above)

· Feed water silica concentration (usually low enough to be neglected)

· Product water quality required

The best way to determine the amount of DC current required is to use the Ionpure

projection tool, IP-PRO: https://ippro.evoqua.com/

Alternatively, it can be estimated using the equation below (based on Faraday’s Law).

NOTE: Contact local Ionpure Technical support for assistance.

DC amps/stack = (1.31)(product flow, L/min/cell)(FCE, µS/cm)/current efficiency, %

Where FCE = measured µS/cm + (ppm CO

2

)(2.79) + (ppm SiO

2

)(2.04)

NOTE: VNX55E and VNX55EX are normally operated at 10 amps DC per module, to

maximize silica removal and boron removal.

Loading...

Loading...