IONPURE

®

VNX CEDI Modules

Page 31 IP-MAN-VNX-1019-EN.pdf

7. TROUBLESHOOTING

The troubleshooting chart in this Section is a diagnostic guide. If the VNX system does

not respond to the recommended solutions, do not attempt further repairs. Call

your Local Service Provider. Before calling:

· Become thoroughly familiar with the module and all troubleshooting procedures.

· Prepare a list of all problems encountered while operating the equipment.

· Have your monitoring log sheets at hand.

· Have your module’s model and serial numbers at hand. This information can be

found on the module end plate on the plumbing end.

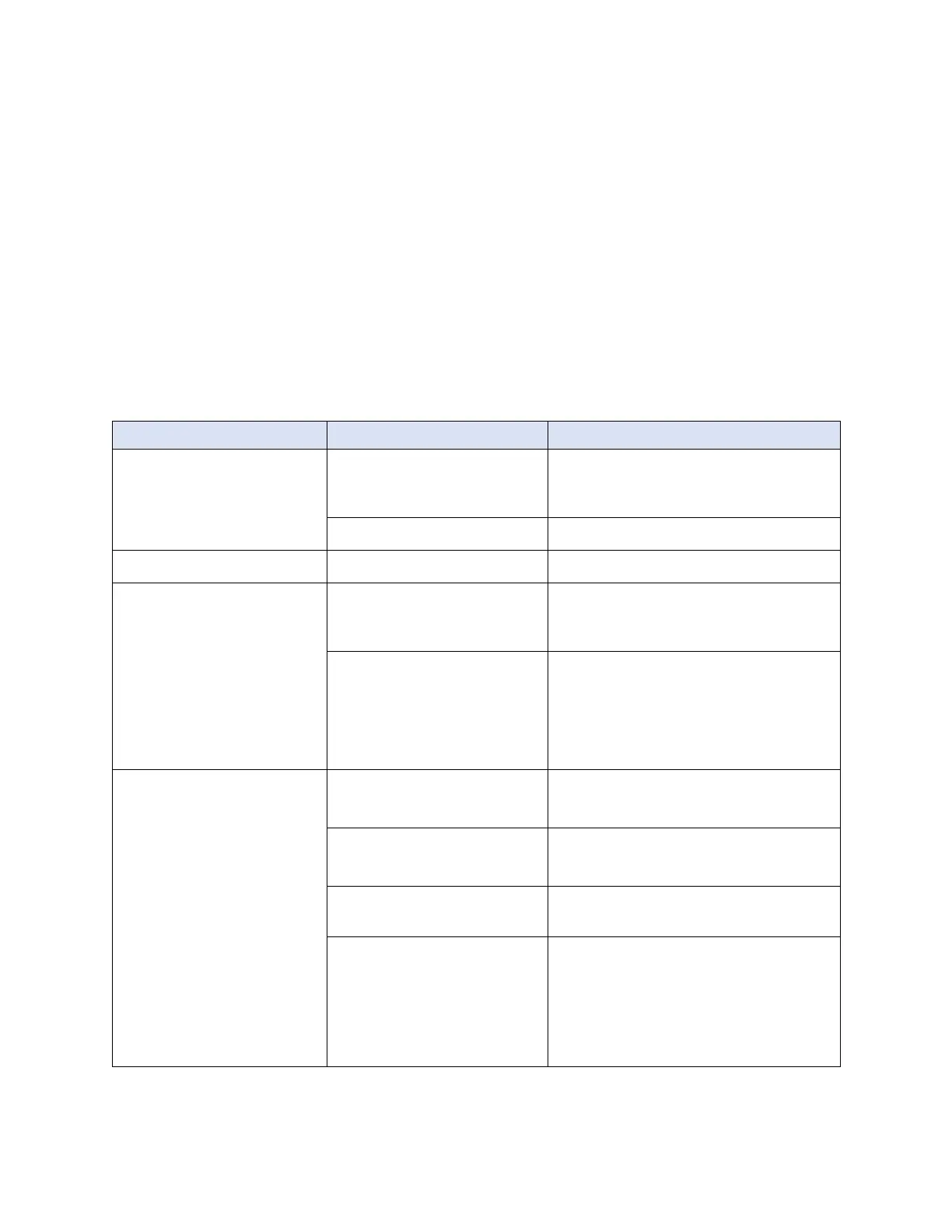

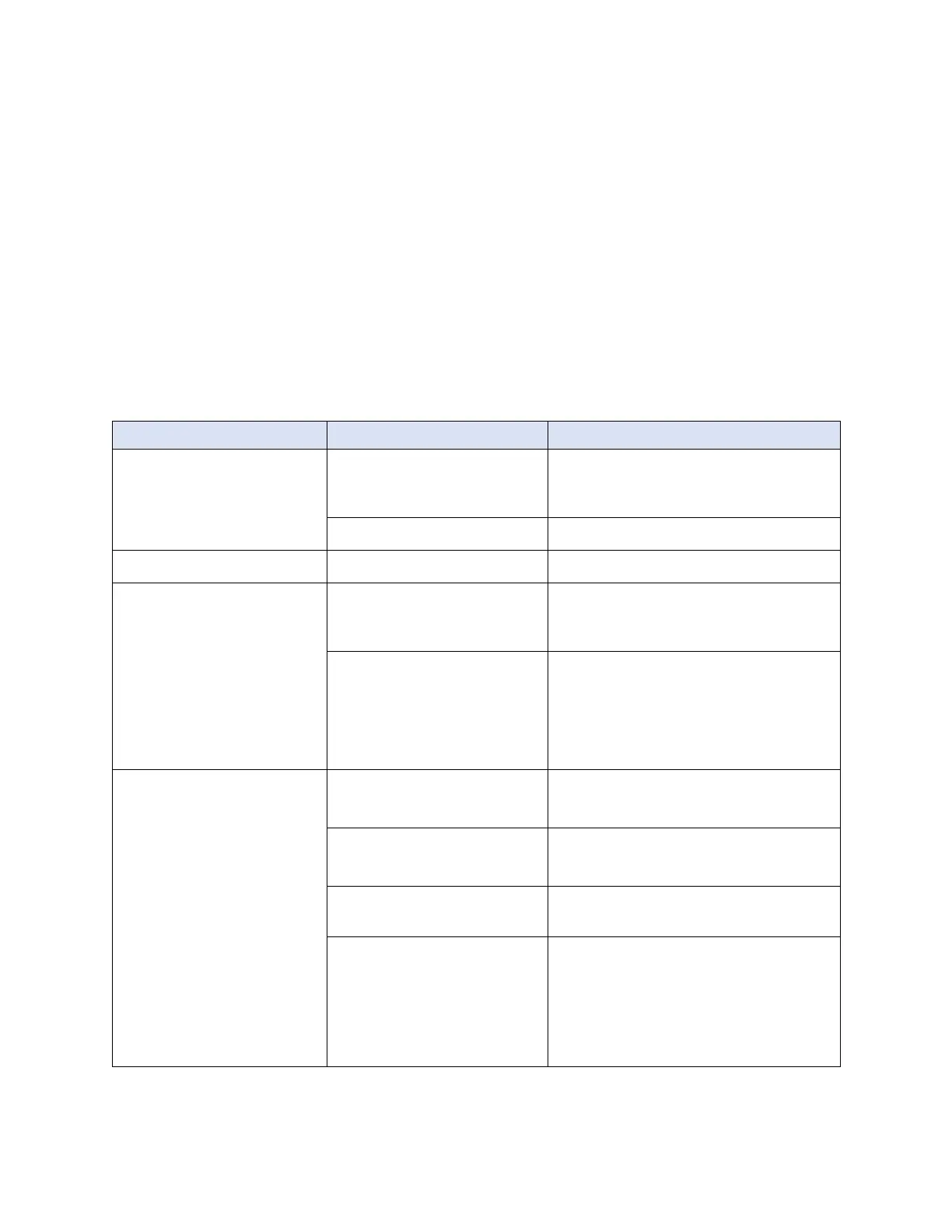

Table 7-1: Troubleshooting Procedures for VNX modules

PROBLEM CAUSE SOLUTION

Module leaks

Module has loosened during

shipment, movement, or

operation

Contact Ionpure Technical support

Module is faulty Contact your Local Service Provider

Plumbing leaks Module adapters are loose Tighten adapters (See Figure 3-4)

Poor water quality with DC

power ON

Operating current too low or

too high

Measure feed conductivity and CO

2

.

Recalculate current according to

Section 4 and adjust as necessary.

Incorrect module electrical

connection polarity

Confirm correct DC+ and DC-

connections (check product and reject

conductivity)

Note: Incorrect polarity can cause

permanent damage

Loss of flow and/or increase

in feed pressure

Module is fouled, scaled, or

oxidized

See Troubleshooting flow chart at the

end of this section.

Obstruction downstream

Check if a downstream valve is

inadvertently closed.

System is plugged with

particulate matter or fouled

See Troubleshooting Flow Chart at the

end of this section.

Loss of feed flow

1. Check if an upstream valve is

inadvertently closed.

2. Check for leaks or if an upstream

bypass valve is inadvertently open.

3. Check feed source output (for

example, a pump).

Loading...

Loading...