IONPURE

®

VNX CEDI Modules

Page 26 IP-MAN-VNX-1019-EN.pdf

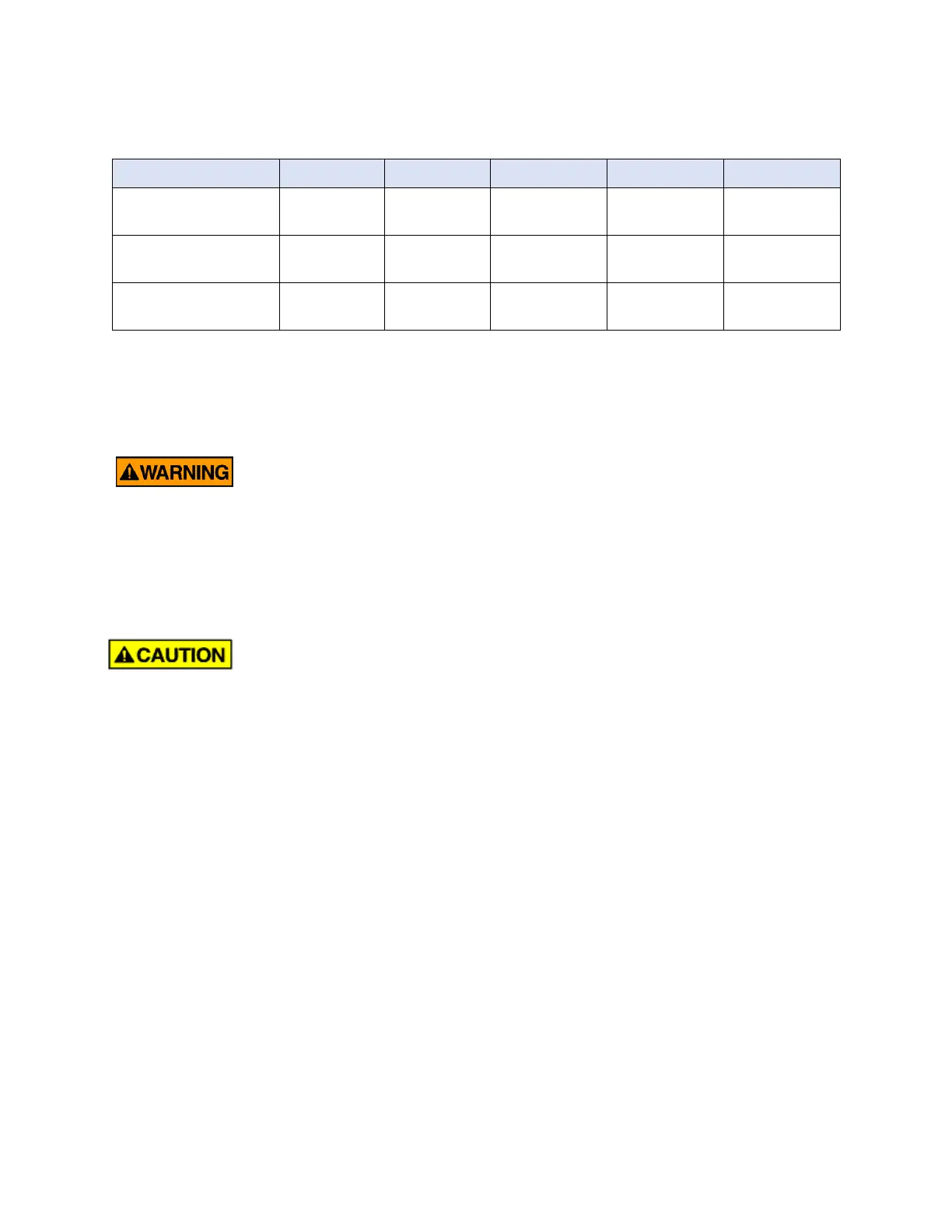

Table 6-1b VNX CEDI Cleaning Flow Rates (per module) continued

MAX MINI 28EP-2 CDIT15 CDIT30

Product gpm

m

3

/h

33-100

7.5-22.7

26.4-79.2

6.0-18.0

13.8-41.3

3.1-9.4

7.5-22.5

1.7-5.1

15-45

3.4-10.2

Reject gpm

m

3

/h

12-35

2.6-7.9

9-28

2.1-6.3

5-14

1.1-3.3

7.5-22.5

1.7-5.1

15-45

3.4-10.2

Pump gpm

Capacity m

3

/h

89

20.3

71

16.2

37

8.4

30

6.8

60

13.6

The preferred cleaning flow rates are nominal product flow (midpoint of ranges above)

and reject flow of 0.35 x nominal product flow (for Gen 2 VNX spacer, except CDIT).

6.5. Chemical Cleaning and Sanitization Precautions

· Avoid direct skin contact with cleaning chemicals. Use appropriate

Personal Protective Equipment (PPE), such as safety glasses,

gloves and protective clothing.

· Flush all hoses and rinse tank with clean water BEFORE adding chemicals.

· Pressure-test CIP system and connecting hoses with water before adding chemicals

to tank.

· To reduce the possibility of chemical sprays, relieve the pressure in chemical lines

before disassembly.

· Follow the manufacturer’s chemical safety instructions on the

container labels.

· Check the pH level in any solution before letting it flow to the drain. Adjust pH as

required to comply with any discharge restrictions.

· Do not run a cleaning solution through the system when DC power is applied to the

module. Make sure the DC power is off before cleaning.

6.6. Typical Procedure for Cleaning or Sanitization

NOTE: The following cleaning procedure is based on the CIP system shown in Figure 6-

1. If your CIP system is different, you may need to adapt this procedure.

6.6.1 Preparation

· Turn off the DC power supply.

· Drain most of water from the CEDI system (to avoid dilution of cleaning solution).

· Close the CEDI system feed valve and product valve.

· Connect the discharge of the cleaning pump to the VNX system feed CIP connection.

· Install new filters in CIP system.

· Connect the CEDI system reject and product CIP connections to the cleaning tank.

Loading...

Loading...