Page 2-2

CORNERMATIC PLUS

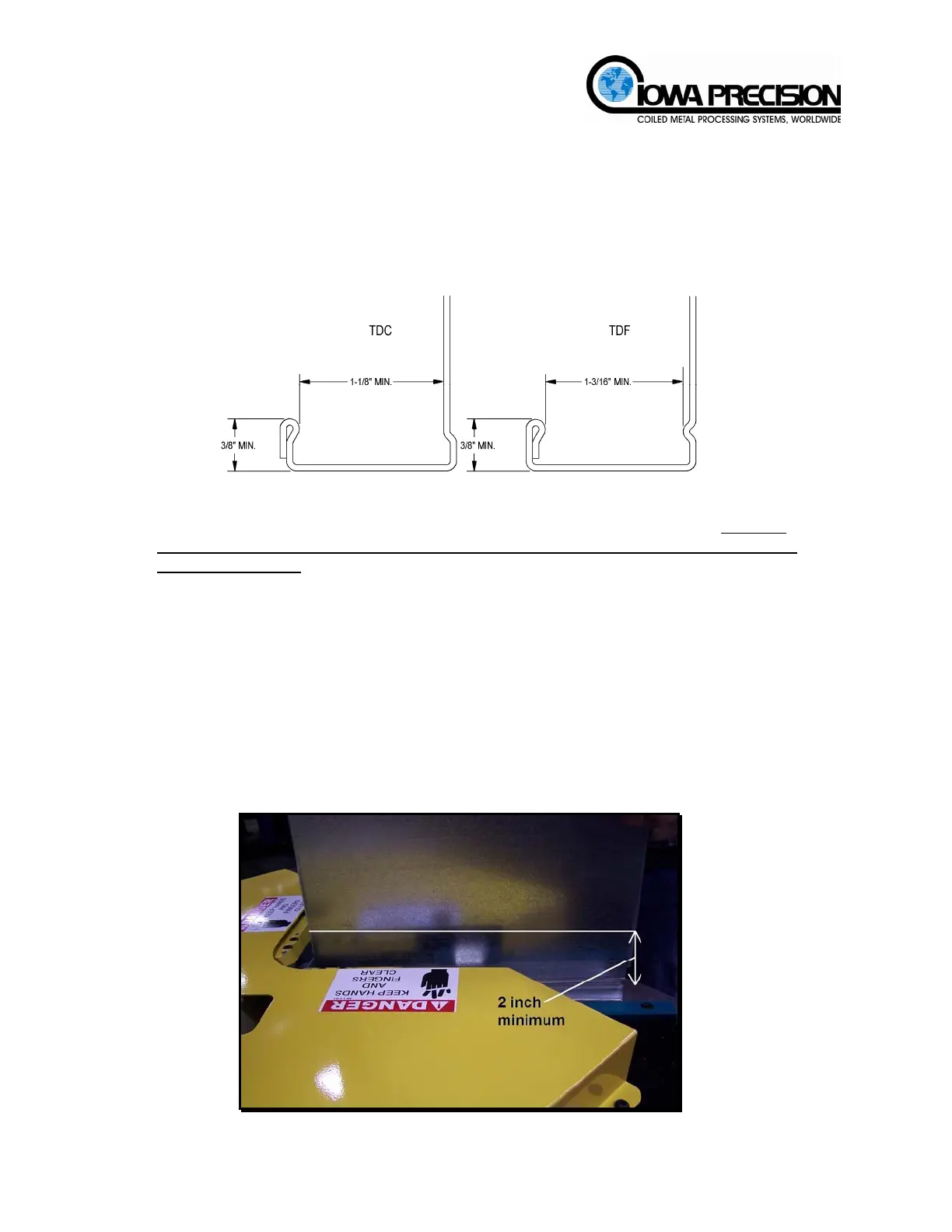

(1) Flange & Corner Requirements

The Cornermatic Plus is designed to insert TDF or TDC corners into ductwork. To ensure

the Cornermatic Plus operates as designed the TDF or TDC flange, corners and duct

fittings must meet specific criteria.

The width of the flange is shown below and must be maintained to ensure the corners are

pressed into the flange completely before the lip of the flange is crimped. Variations in

width will cause the corners to not seat completely or the corners may not be secured

properly.

Figure 2-2 TDC and TDF Duct Fitting Flange Requirements

The corners used in the Cornermatic Plus must also meet specific criteria. The only

corners guaranteed to work in the Cornermatic Plus are DuctMate corners or Mestek

Machinery Corners. Please contact Mestek Machinery for information on ordering

DuctMate or Mestek Machinery corners.

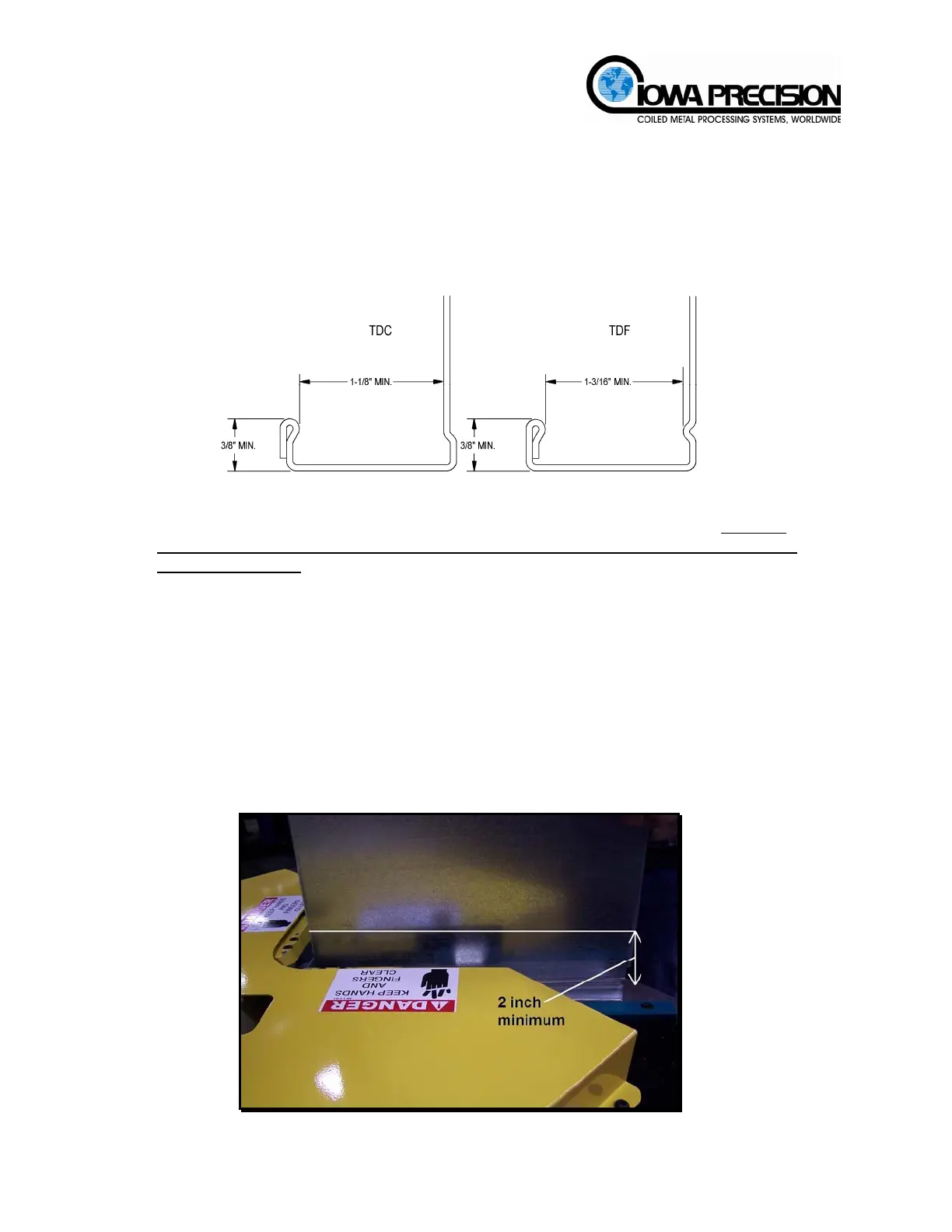

(2) Duct Requirements

To ensure proper corner insertion and crimping, the duct fitting must have a minimum 2

inch straight before the transition angle begins. This 2 inch straight is critical for heavier

gauges (16 or 18).

Also, critical for proper corner insertion and crimping is having proper lock seams.

Partially open or mismatched lock seams are just two of the common imperfections that

can cause problems inserting and crimping corners.

Proper maintenance, upkeep and adjustment of the duct making equipment are essential.

Please contact the Mestek Machinery service department regarding production of

ductwork.

Figure 2-3 Fitting Height Minimum

H. WEISS MACHINERY & SUPPLY

H. WEISS MACHINERY & SUPPLY

PHONE: (718) 605-0395 - www.hweiss.com

Loading...

Loading...