38

Set Overflow percentages

Step 1 – Place the Function dial to the FLOW SENSING position. Enable ow sensing if its disabled.

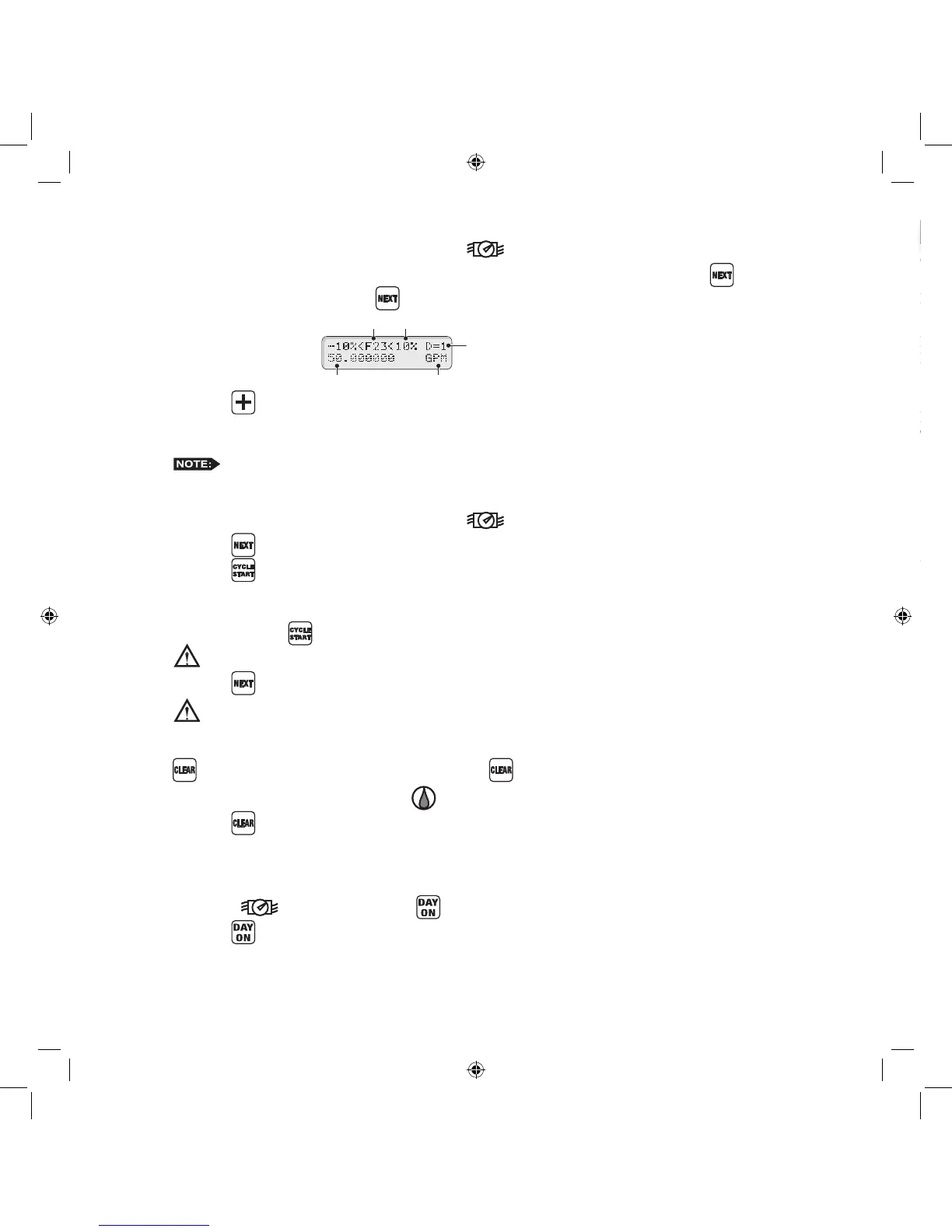

Step 2 – Select the station number being edited. While in the K Value/Size Code screen, press the button to advance

to the Overow screen. Press the button to advance the Station number.

Step 3 – Press the button to adjust the Overow percentage . This value will set the maximum ow value limit.

When actual ow reads above the maximum, the ow alarm LED will activate and an audible tone will beep

every 30 seconds. MC-E will also ash in the display which station posted a faulty ow reading.

The factory default Overow percentage is 50%. Underow is not monitored.

Set Flow Delay Time

Step 1 – Place the Function dial to the FLOW SENSING position. Enable ow sensing if its disabled.

Step 2 – Press the button to advance the display to the Underow/Overow screen.

Step 3 – Press the button to adjust the ow delay time. The ow delay time is the period that MC-E will wait

after activating a particular station before reading the ow. This delay period allows the irrigation system to

normalize to get an accurate ow reading. The default ow delay time is set at 1 minute but can be adjusted up

to 9 minutes using .

IMPORTANT! For stations with drip setup, use longer delay times of 6-9 minutes.

Step 4 – Press the button to advance to the next station number and adjust the remaining station’s ow delay.

IMPORTANT! Station 2 is no longer a regular station. Leave its settings at 0.

Clear Flow Alarms:

Press the button. Use the procedure below if pressing the button did not clear the alarms.

Step 1 – Place the Function dial to AUTO/RUN position.

Step 2 – Press the button. This process will clear all alarms except for unexpected ow alarm.

Clear Unexpected Flow Alarms:

Step 1 – To clear the unexpected ow alarm, disable the ow function by placing the function dial to the FLOW

SENSING position and press the button to deactivate ow

Step 2 – Press the button again to reactivate the ow function. By deactivating and activating the ow sensing, it

will the unexpected ow alarms.

Specications

Cabinet Dimensions:

Small Metal Cabinet Unit: (9.71” H) x (10.68” W) x (4.25” D) [(24.66 cm H) x (27.13 cm W) x (10.79 cm D)]

Large Metal Cabinet Unit: (12.37” H) x (14.32” W) x (4.75” D) [(31.42 cm H) x (36.37 cm W) x (12.06 cm D)]

Input Voltage:

Domestic: 115 VAC, 50/60 Hz; Secondary - 24 VAC, 50/60 Hz, 50VA Class 2 Transformer, UL and CSA Listed.

Export: 250 VAC, 50/60 Hz; Secondary - 24 VAC, 50/60 Hz, 50VA Class 2 Transformer, CE and TUV Listed.

Output Voltage:

Station Output Voltage: 24 VAC with 1.00 Amp Max

Maximum Master Valve Current: 1.00 Amp

Total Output Current to Valves: Not to Exceed 1.68 Amps including Master Valve/Pump Start

Storage Temperature:

4º F to 140º F (-20º C to 60º C)

Operating Temperature:

32º F to 160º F (0º C to 60º C)

Humidity:

95% RH, Non Condensing, @ 100º F (37.8º C)

Loading...

Loading...