T

he

reference

in

surface

TreaTmenT

International

Surface

T

echnologies

istsurface.com

28

DCM600 to 1800 - Instruction Manual

1.1 — Requirements for feeding matter

The controller has a power «universal» power that connects input power of 120 V AC to 240 V AC. The input

voltage must be between 85 and 270 V AC / 50 Hz or 60 No change in circuit is required when switching between

these tensions. The values of solenoid, however, must be adjusted to accommodate the voltage of the selected

line.

1.2 — Terminal connections of the DCT1000

Line solenoid valve and connections are located on the lower edge of the map below the plastic. The terminal

block is a connector type «Euro» that grips the wire into the connector body. The connector accepts wires from

14 to 22 AWG. The wire should not be stripped of more than 0.25 inches to avoid short circuit or expose bare son

creating a potential hazard of electric shock.

To help you determine the right to bare wire lengthways required a mark length of wire stripper is provided in the

lower right corner of the map. The connector system used on the DCT1000 is specied for a single connection,

but you can splice several together if local codes permit and that the practices of performance are met.

To power the master controller and extensionner dr channels, the supply must be connected to line L1 and L2

(see dimensional specications, Figure 1). Connect the solenoid between the selected output and the common

solenoids. The common solenoid and L2 are connected internally.

The contacts of the switches connected to the control inputs at the top of the table above should be isolated

and only connected to the appropriate terminal and common terminals.

The following sections describe connections to external switch. See Figure 2 for the connection of the switch.

1.2.1 Connection of external pressure

The controller can be used with a limit switch or external pressure sensor to provide the cleaning process the

request. The high limit and low limit inputs can be used for this purpose. A simple on-o can be established

with a single pressure switch connected to the input of the upper limit. Better control can be achieved with a

limit gauge high and low as the Photohelic Dwyer ®. In this mode of application, time, free time, and the delay

of the cycle can be programmed to set the cleaning cycle. A three-pin terminal block (TB3) to connect the

outside running up and down (see Figure 2 on next page). These switches should be isolated from contacts.

The common line should not be grounded or protective equipment on the ground because they can introduce

electrical noise and cause a malfunction or possible damage to the sequencer. The operations of these entries

are as follows (see next page):

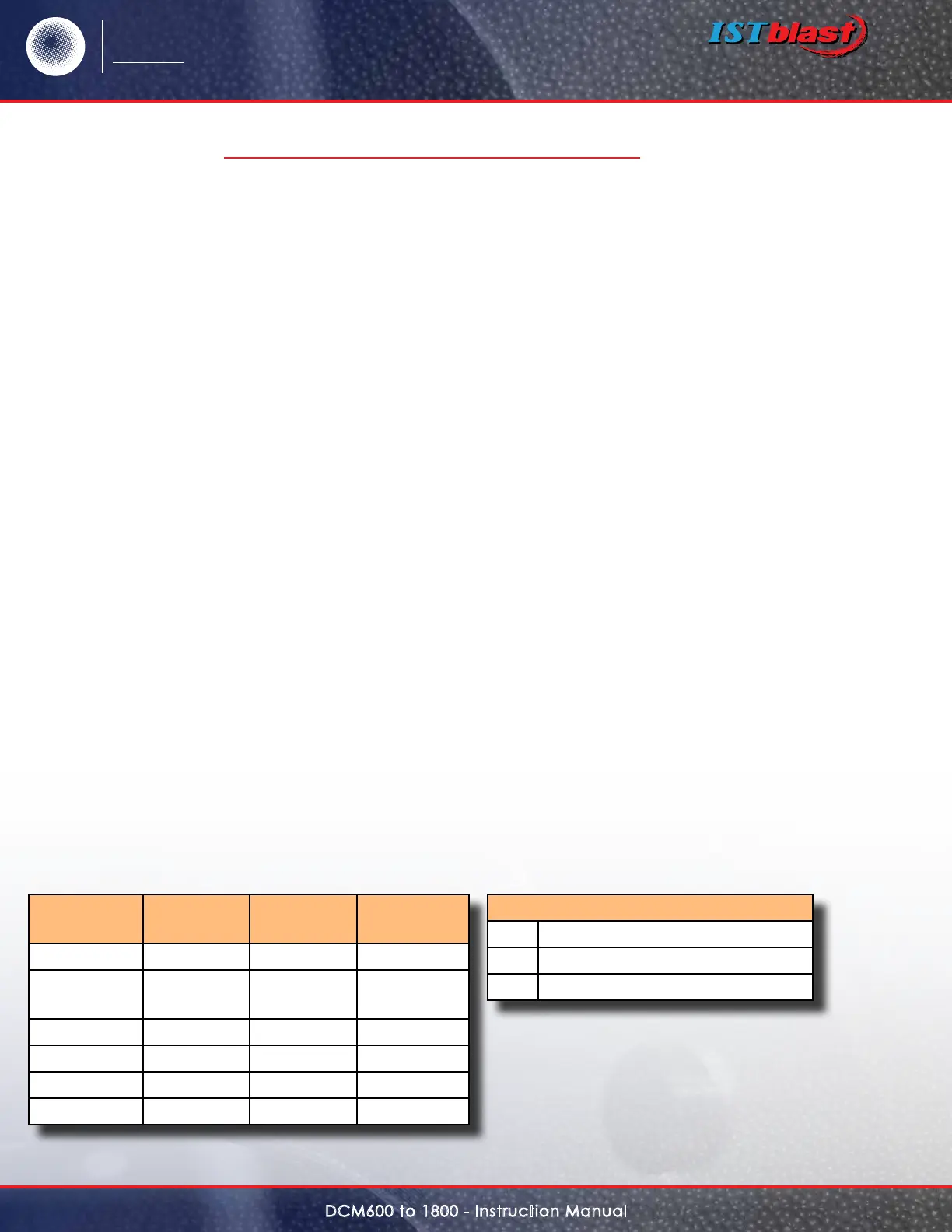

Operation

in progress

Switch

lower limit

Switch

upper limit

Next

operation

Waiting Open Open Waiting

Waiting or

pending

X Closed In progress

Waiting Ø Open Waiting

Waiting Closed Ø In progress

Run Closed

ß

In progress

Hold Closed Ø In progresss

Legend

X Is open or closed

Ø Transition from open to closed

ß

Transition from closed to open

1.0 INSTALLING THE DCT1000 CONT’D

Loading...

Loading...