ELEMENTS INSTALLED

ELEMENTS INSTALLED

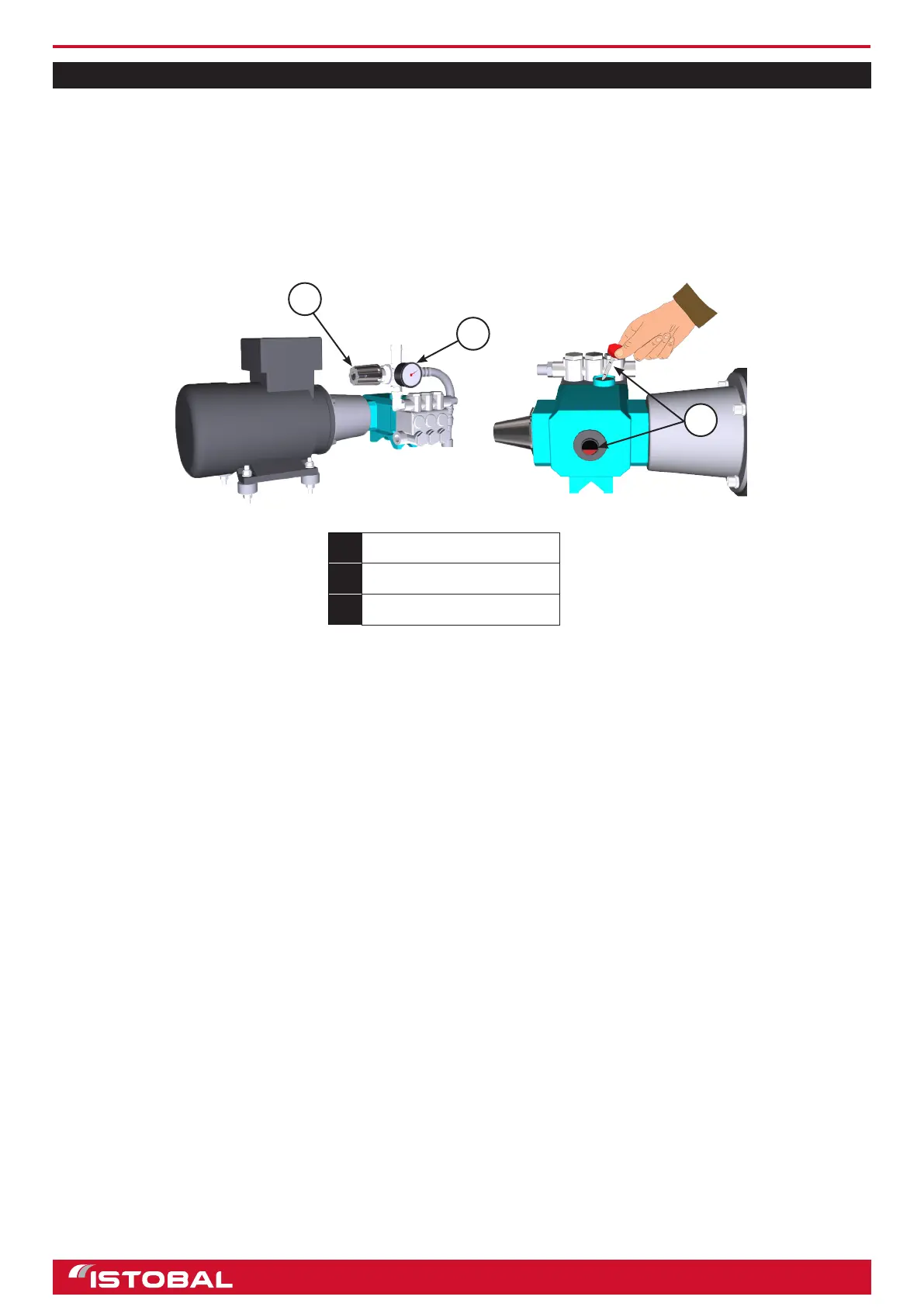

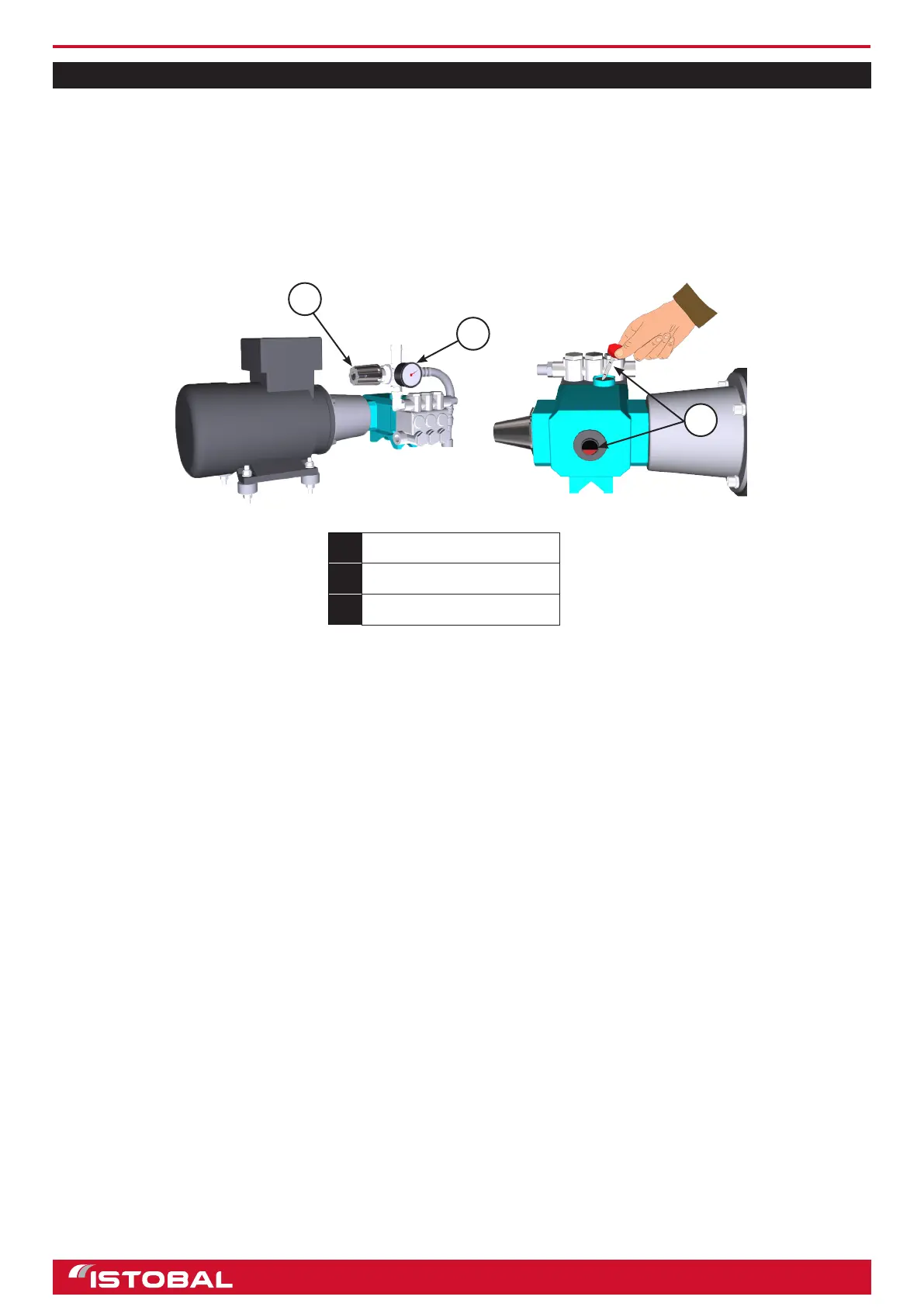

HIGH PRESSURE PUMPS

The output pressure of the high pressure pumps should be constant at 80 bars. The gauge (A) installed on the pump

is for monitoring the output pressure of the pump.

Due to wear on the gun nozzles, a drop in pressure may be experienced. This can be corrected by the pressure

regulating valve (B). Replace the nozzles when the wear becomes excessive.

A Pressure gauge

B Pressure regulator

C Oil level

Check the level of oil in the pump by using the dipstick or the sight hole on the back of the crankcase (C).

MAINTENANCE POINTS

Daily

• Check the oil level on the pump susing the dipstick or the sight hole on the back of the crankcase (A) and ll

when necessary with oil ISO68. The rst oil change should be after the rst 50 hours of operation and every 500

hours after that.

Weekly

• Check that the pressure on the output gauge is as recommended (80 Bar). To regulate the pressure during pump

operation, actuate the regulating valve and then check the pressure on the gauge.

• Due to wear on the gun nozzles, a drop in pressure may be experienced. This can be corrected by the pressure

regulating valve (B). Replace the nozzles when the wear becomes excessive.

C

A

B

53

Loading...

Loading...