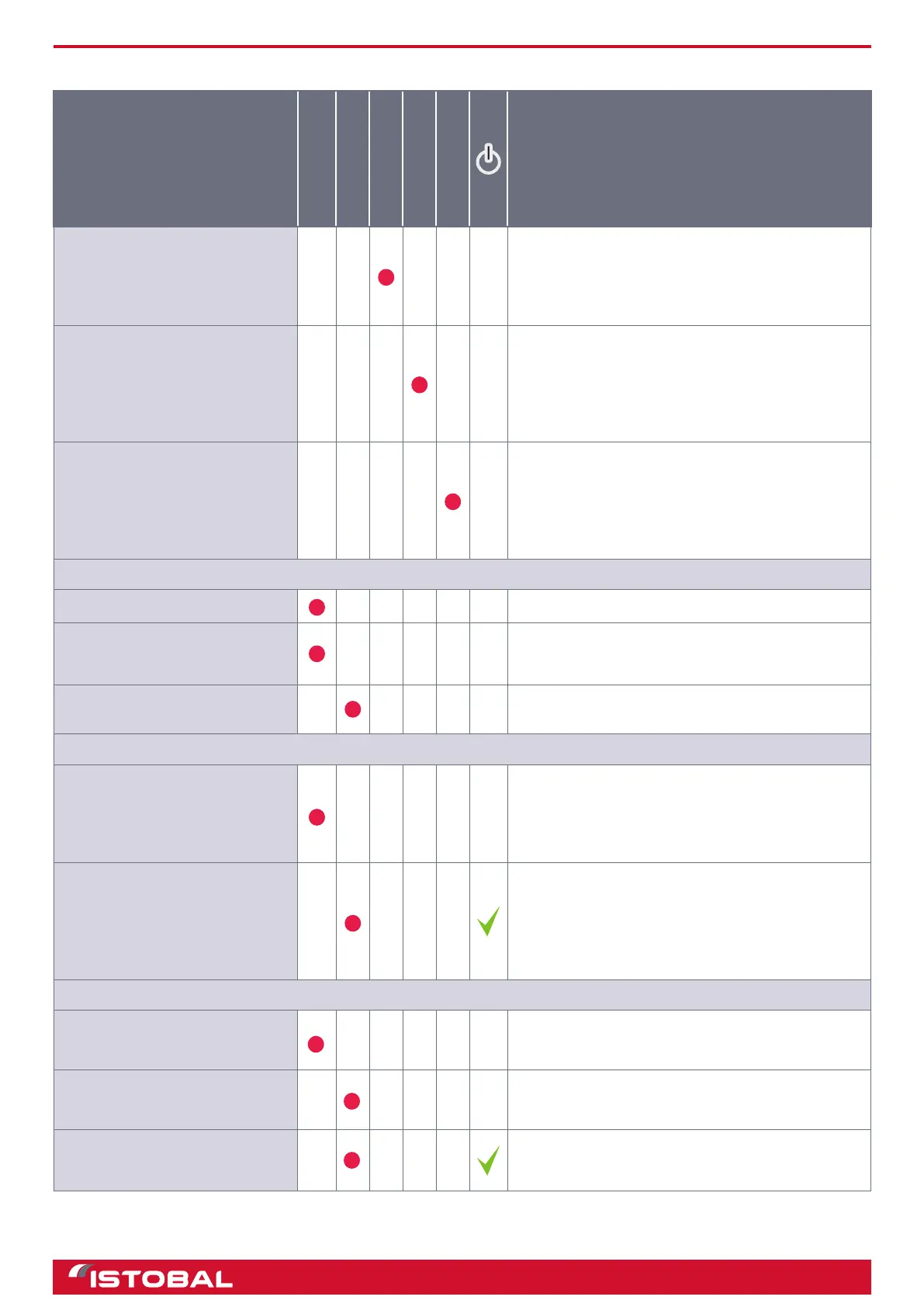

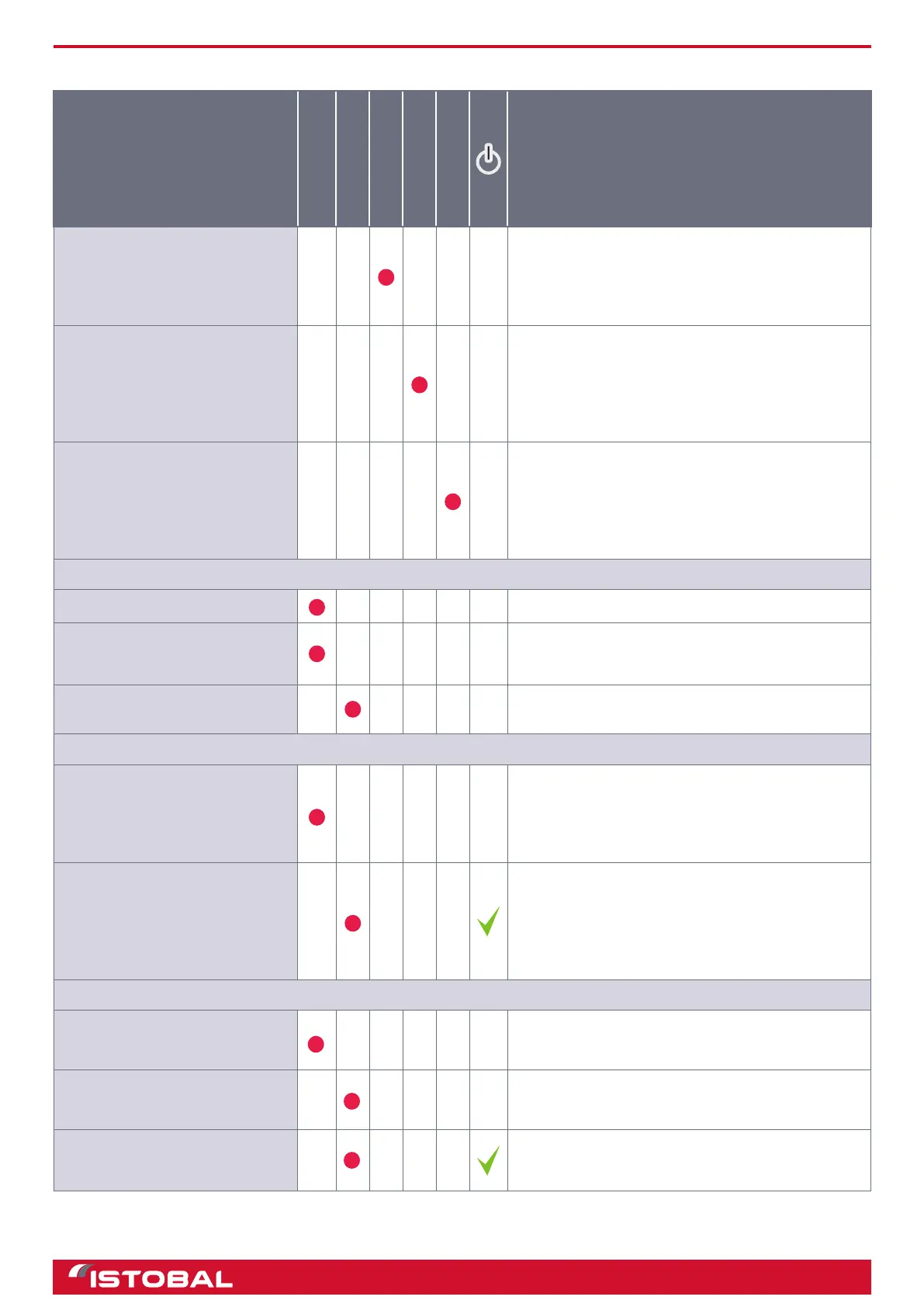

MAINTENANCE

MAINTENANCE TABLE

POINTS FOR

MAINTENANCE

DAILY

WEEKLY

QUARTERLY

SIX-MONTHLY

ANNUAL

RECOMMENDATIONS

Nozzle cleaning and disinfection

Cleaning and disinfection of all nozzles and pipes.

As laid down by current regulations, car-wash

facilities should be supervised by organisations

competent in Legionella prevention and control, as

per the terms set in the legislation of each country.

Emptying the tanks

Emptying of all the tanks in the facility including

disposal-stage tanks. As laid down by current

regulations, car-wash facilities should be

supervised by organisations competent in

Legionella prevention and control, as per the terms

set in the legislation of each country.

Emptying and cleaning the tanks

Emptying and cleaning of all the tanks in the facility

including disposal-stage tanks. As laid down by

current regulations, car-wash facilities should

be supervised by organisations competent in

Legionella prevention and control, as per the terms

set in the legislation of each country.

WASH BAY

Bay cleaning

x

Clean the wash bays.

Water leaks on bays.

x

Check for leaks on the guns, lances or rotating

arms of the wash bays as well as inside the jet

wash cabinet.

Cleaning the outside

x

Clean the outer structure of the machine with water

at low pressure (max. 2 bar/28 psi).

HIGH PRESSURE PUMPS

Level and state of the oil in the

pumps

x

Check the oil level in the pumps and ll when

necessary with oil ISO68.

Check the outow pressure of the

pumps

Check that the pressure on the output gauge is

80 bar. To regulate the pressure during pump

operation, actuate the regulating valve and then

check the pressure on the gauge.

HOT WATER GENERATORS

On diesel oil generators, check

the level of diesel in the tank

x

Check the level of diesel oil in the tank and ll it if

necessary with heating oil type “C”.

Check the diesel oil lter on the

tank’s inlet.

x

Check to see how dirty the lter is, and replace it if

necessary.

Check the dosing pump of the

scale preventer for boilers

Check that there are no faults showing on the con-

trol panel viewer of the dosing pump and that it is

dispensing the scale preventer properly.

48

Loading...

Loading...