1.4 Wiring and mounting

1.4.1 Power wiring

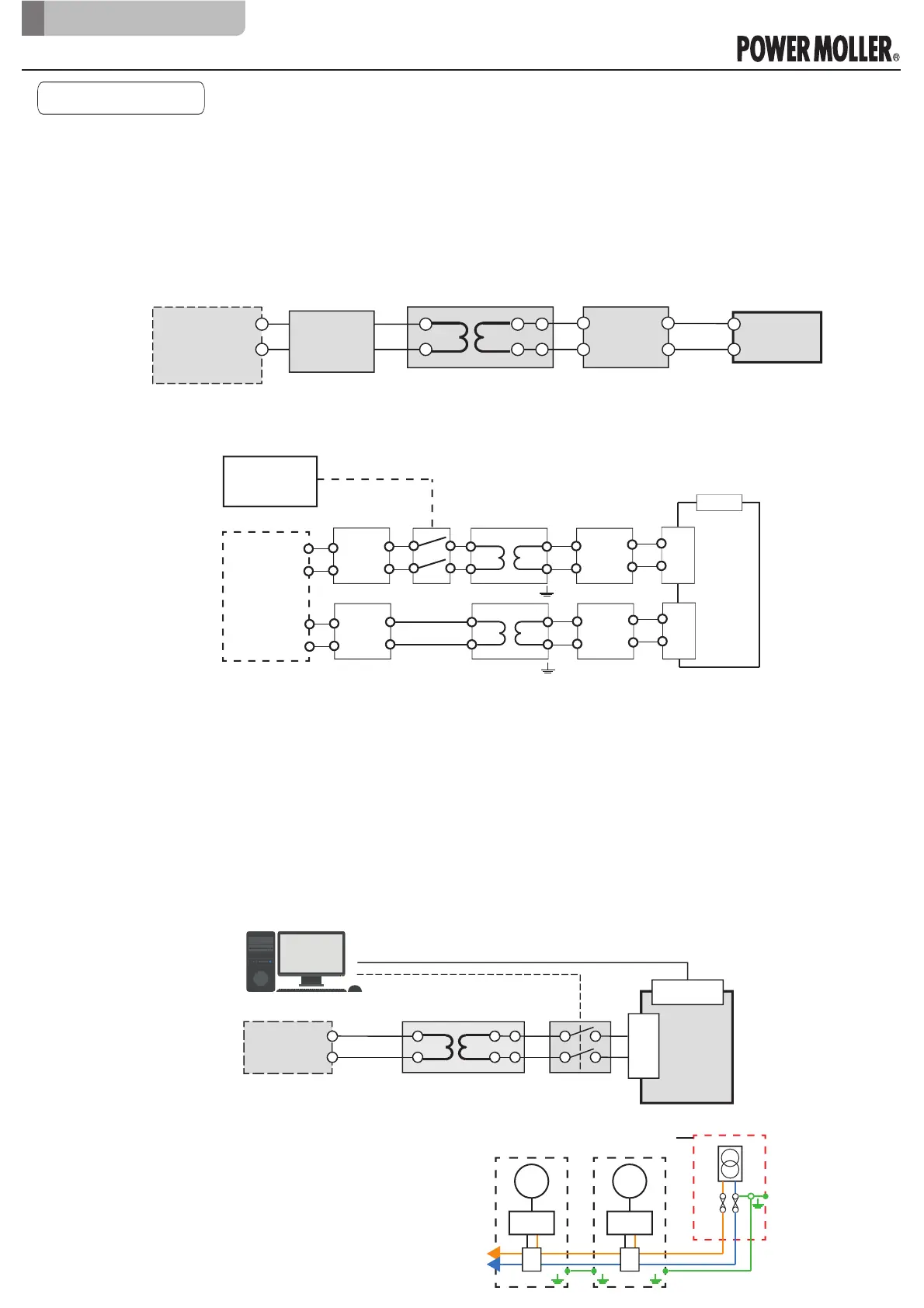

(1) Requirement for overcurrent protection

Installation of an overcurrent protection device may be required to conform to specific safety

standards (such as UL60950-1). In such a case, be sure to install the overcurrent protection device

as shown below. It is not necessary to install overcurrent protection if there isn’t any requirement for

overcurrent protection in the specifications for DC power supply.

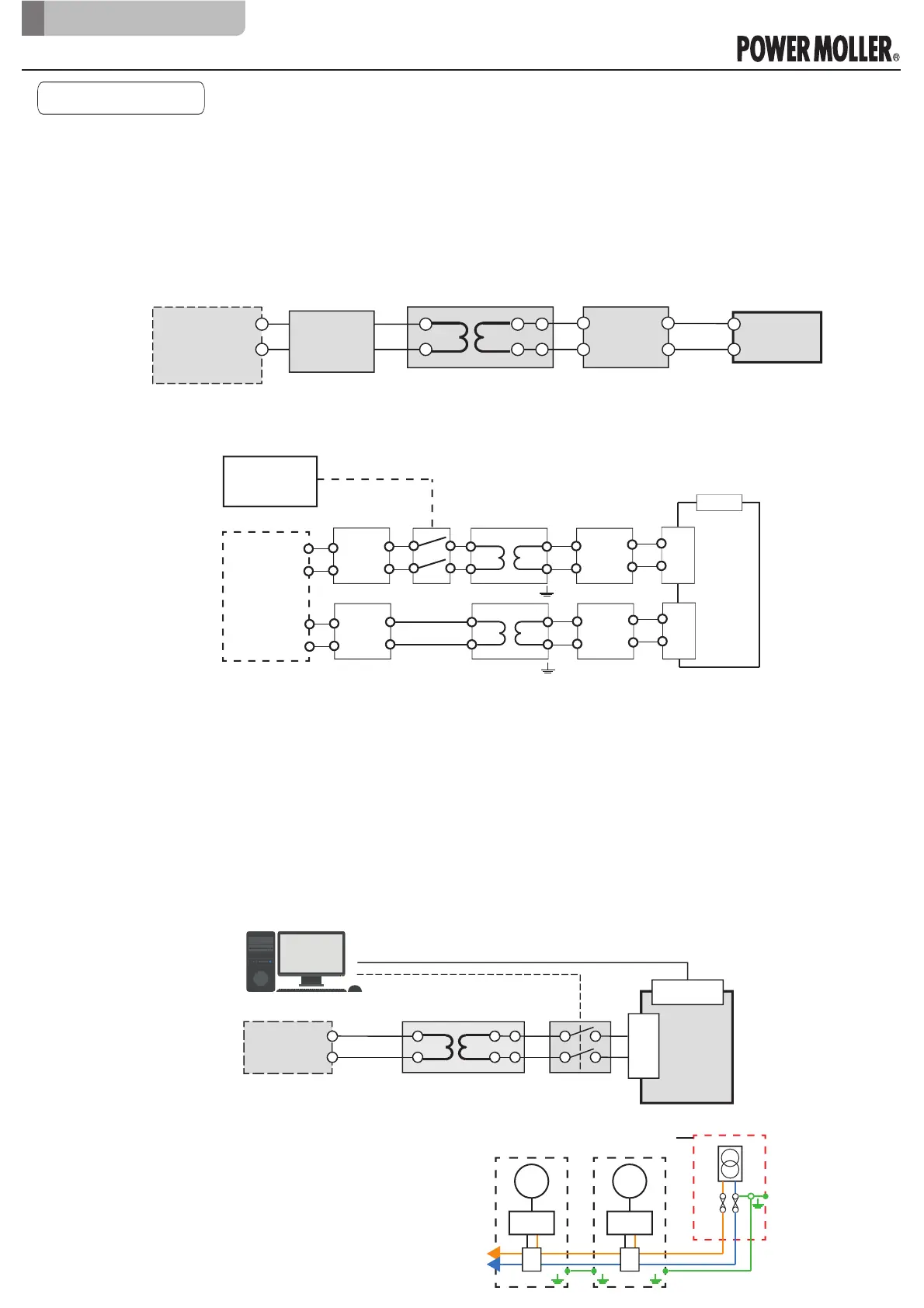

(3) Addition of shutdown circuit for motor power when an error occurs

If motor power needs to be shut down when an abnormality occurs, such as overload or abnormal

temperature, add a shutdown circuit for the motor power circuit. The IB will turn the motor off if these

conditions occur but motor power will need to be disconnected by using of an external device if necessary

for the application.

Abnormalities cannot be detected from communication data if the driver card’ s communication function is

not used. In order to shut down motor power, adding an external device to detect the abnormality and

disconnect motor power is necessary.

AC power

at factory

IB

(Overvoltage category 2)

Overcurrent

protection

DC power supply(Overvoltage category3)

AC power

at factory

IB

DC Power supply

Ethernet

Ethernet communication

Motor power

SW1

Contact for blocking

PC for control or PLC

AC power at

factory

Overcurrent

protection

(2) Installation of overcurrent protection

Install an overcurrent protection device to 24V DC line if any power supply other than limited

power source is used.

ESM safety system

according to local

safety rules

Overcurrent

protection

Overcurrent

protection

Motor

Ethernet

Overcurrent

protection

Overcurrent

protection

Control

IB

24V

24V

0V

0V

DC Power supply

DC Power supply

AC Power

at factory

SW1

EMS contact

MDR

Circuit

board

MDR

Circuit

board

L1 L2 L3

AC single or 3ph power supply

24V 0V

Devices grounding

Ensure that all power supplies are grounded

between their 0V output and the main earth terminal

and that all conveyor metalworks are effectively

bonded together and back to the main earth.

Original notice - A1.2

11

Wiring and mounting

IB-P05 Technical documentation

1. Introduction

• An EMS safety system should be installed according to risk analysis of the machine. EMS

relay is a safety function and must not be used as run/stop signal.

• EMS relay contact must be set before DC motor power supply, to avoid any electrical noise

(contact bounce, arching, etc…) that could damage electronic devices.

Loading...

Loading...