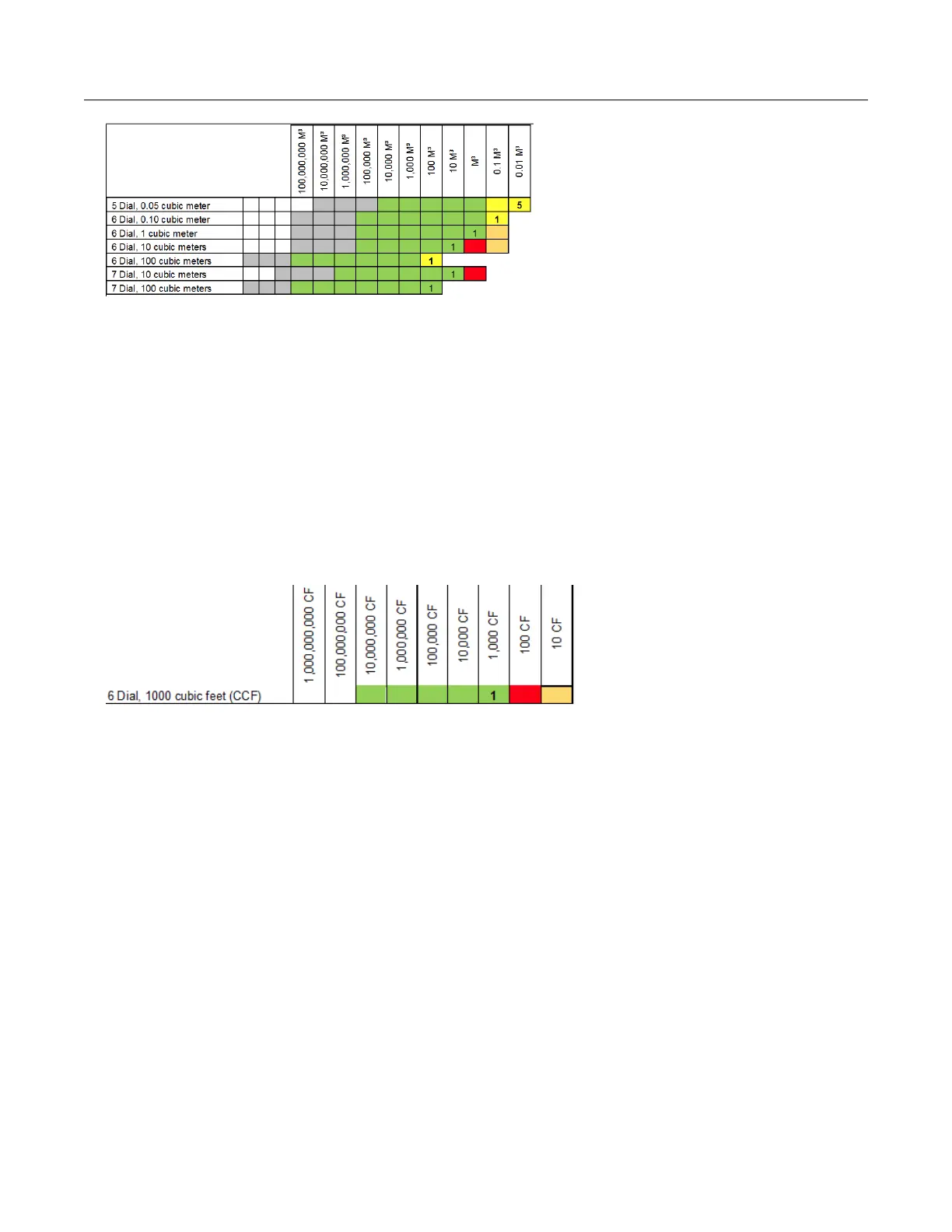

Programming example: Endpoint programmed for 6 dial, 1000 cubic feet CCF.

1. Enter the initial index read. For this example, the initial read is 123456 where 6 = 600

cubic feet. After the initial programming, an endpoint read will result in a reading of

1234560 where the least significant digit is in 10's of cubic feet. Since counting is with a

drive rate of 1000 cubic feet and the reading is transmitted in 10's of cubic feet, the last

two digits of the reading will not change.

2. Program the endpoint to 123456.

3. Read the endpoint. The result should be 1234560 with the zero added to put the reading

in 10's of cubic feet.

4. Add one count. The result should be 1234660. Notice that the last two digits of 60 do not

change.

Mercury X-Blank options

Endpoints (ERT modules) can be programmed with one of the Mercury X-Blank options.

There are 1, 2, 3, and 4 blank option available. Blank options are set up as a what-you-see-

is-what-you-get (WYSIWYG) configuration. The values are not set in cubic feet or cubic

meter standards. The Mercury X-Blank options are used in configurations where the system

receives pulses from a corrector or instrument that can change pulse values and has

configurable display digits. The Mercury-X Blank options allow users to program the

endpoint to match the configuration of the corrector or instrument.

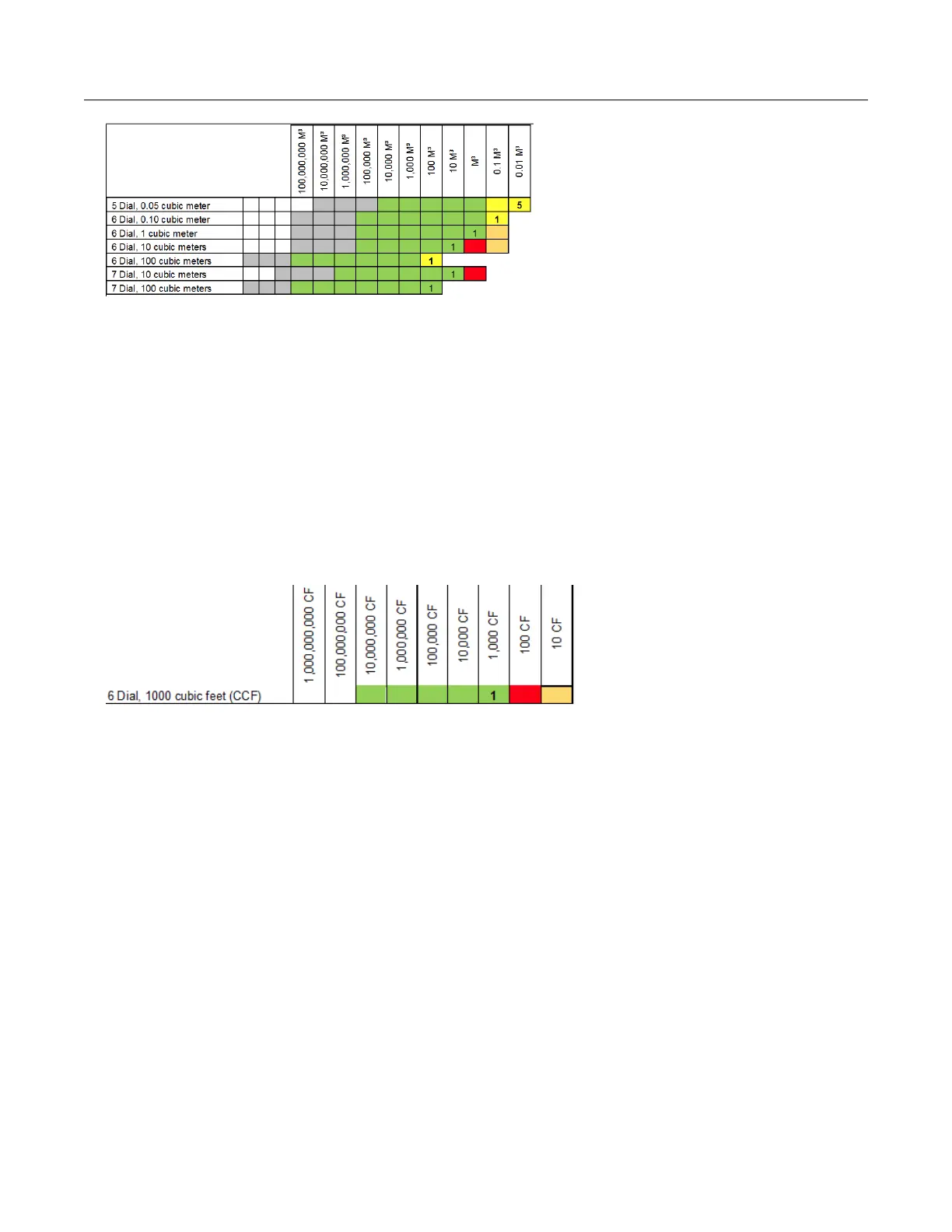

Check Endpoint functions

The FDM Check Endpoint function triggers users to input the number of dials and drive rate

if a Check Endpoint is requested for an endpoint programmed for 5, 6, or 7-dial meter

configurations. The request to input the dial and drive rate information happens only if the

system has more than one option using the same count rate and rollover variable enabled in

their FDM business unit.

100G Series Remote Module Programming

100G Series Gas ERT Module Installation Guide, Remote Mount TDC-0824-017 16

Proprietary and Confidential

Loading...

Loading...