26

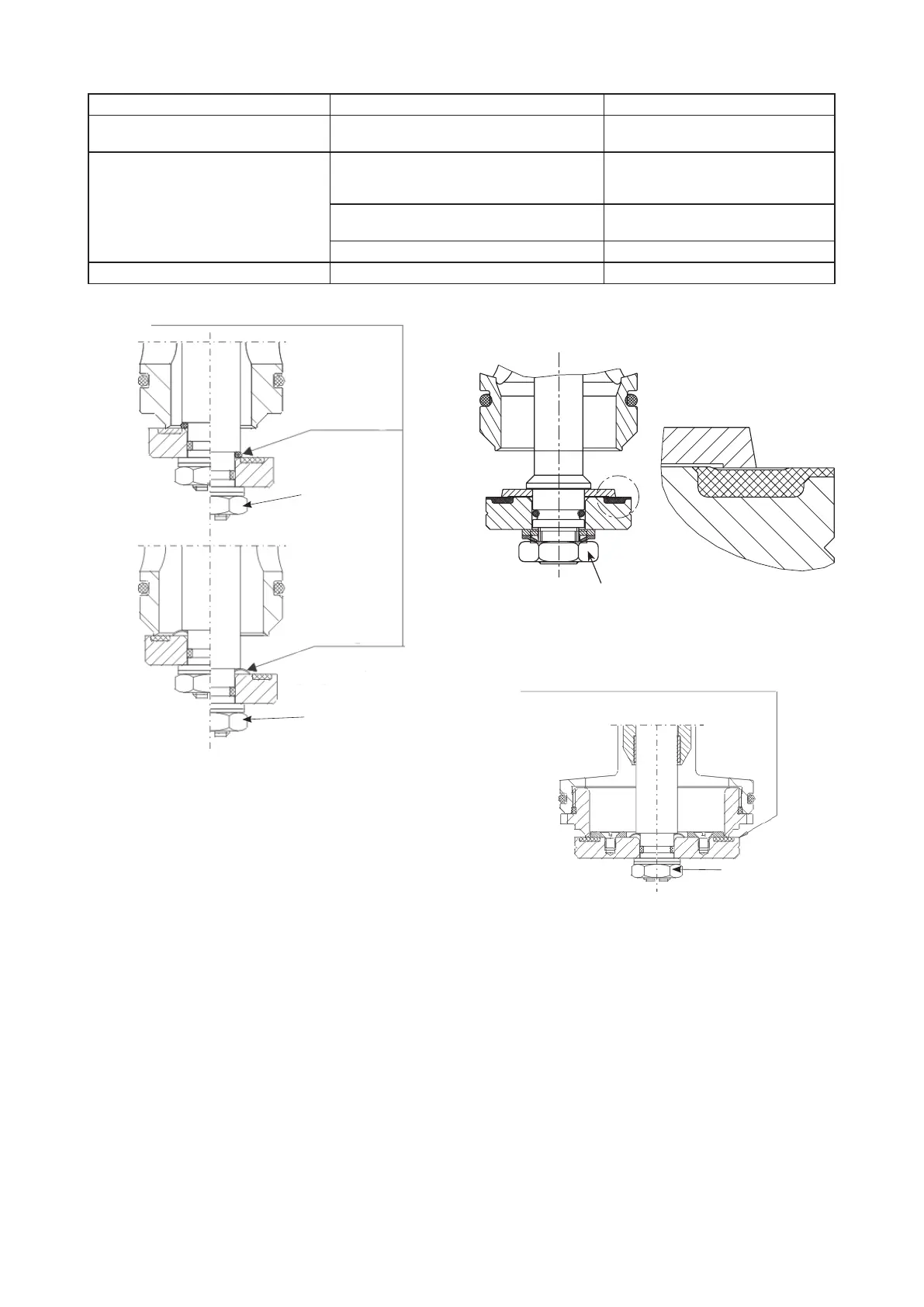

Note

For orifice ø 24 / ø 31 / ø 42, instead of an O-

ring or a compensation disk, install the flow disk

between the valve disk and the collar at the valve

rod.

Remove the O-ring (valve disk seal) before as-

sembling the flow disk and then reinstall it.

The valve disc assemblies are used for orifice

ø 54 & 82. You don‘t need remove the compen-

sation disk.

Standardmodel with

Model with valve disk assy

for orifice Ø54 & Ø82

Model with flow disc

for orifice ø 24 / ø 31 / ø 42

O-Ring

Orifice Ø24

SW 17

Compensation

disc

(Orifice Ø31,

Ø42 and Ø54)

SW 17

SW 17;

SW 19 (DN 80)

SW 17

Flow disc installation.

Remove inspections plate from body (Pos. No 8 of material list). Loosen hex nut; insert a screwdriver

into the slot of the thread to counter hold the valve rod. Remove valve disk, washer and lock washer.

Remove O-ring or compensation disk and install flow disk

(pay attention to correct position!).

Insert valve disk, washer and lock washer. Fasten hex nut (max 5 Nm), counter hold

with a screwdriver (blade: 8 x 1.2or 9 x 1.4 mm).

Reassembling inspections plate on body, check tightness after assembly!

Flow Disc for flow volumes < 10 % of qmax (< 1:10)

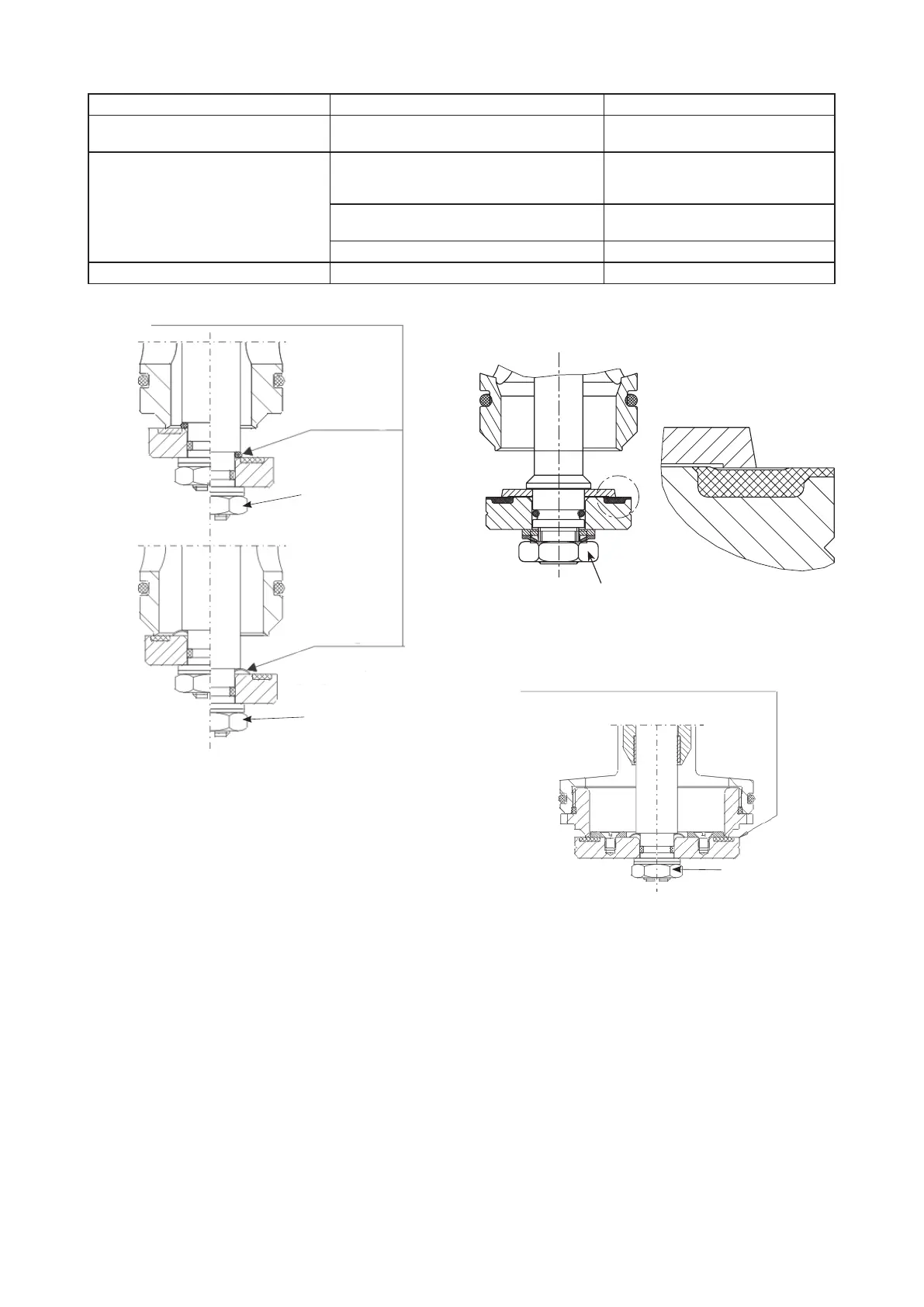

DN 25 DN 50 DN 80

Design framework till April 1998

111-163-10 orifice ø 24

Design framework till April 1998

111-163-10 orifice ø 24

Valve disk assy. 111-360-20

orifice ø 54

Design framework from Mai 1998

onwards (recess at the bottom)

111-363-10 orifice ø 24

Design framework from Mai

1998 onwards(recess at the bot-

tom)111-163-10 orifice ø 24

111-363-15 for orifice ø 42

111-163-15 for orifice ø 31

Valve disk assy. 111-560-20

orifice ø 82

111-363-15 for orifice ø 42

111-163-15 orifice ø 31 Valve disk assy. 111-360-20 orifice ø 54

pay attention to

correct position

Loading...

Loading...