What causes excessive vane-tip runout of the impeller in ITT Goulds Pumps IC?

- UuwallaceSep 13, 2025

If there is excessive vane-tip runout of the impeller in your ITT Water Pump, it is probably because the vane is bent. Replace the impeller.

What causes excessive vane-tip runout of the impeller in ITT Goulds Pumps IC?

If there is excessive vane-tip runout of the impeller in your ITT Water Pump, it is probably because the vane is bent. Replace the impeller.

| Seal Type | Mechanical Seal |

|---|---|

| Casing Material | Cast Iron |

| Head | Up to 400 feet |

| Inlet/Outlet Size | 1. 5" to 8" |

| Material | Cast Iron, Stainless Steel |

| Temperature Range | -20°F to +250°F |

Purpose of the manual and how to request additional information.

Critical safety warnings, hazard levels, terminology, and symbols for safe operation.

Details regular and explosion-proofing standards for product compliance.

Outlines coverage, limitations, and claim process for product warranty.

Special care for explosive atmospheres and ATEX conformance requirements.

Guidelines for inspecting, transporting, and storing the product safely.

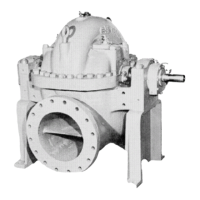

Overview of the pump's construction, casing, impeller, seal chamber, and power end.

Details the fields and explanations found on the pump's nameplate.

Precautions, pump location, and foundation requirements before installation.

Methods for mounting the baseplate using shims, jackscrews, spring, or stilt.

Steps for mounting the pump and driver onto the baseplate and installing the coupling.

Procedures for checking and performing pump-to-driver alignment for optimal performance.

Step-by-step instructions and required equipment for grouting the baseplate.

Guidelines and checks for suction, discharge, bypass, and auxiliary piping.

Crucial steps and warnings before initiating pump startup.

Detailed instructions for safely removing the coupling guard.

Procedure to verify the correct direction of pump rotation.

Steps for correctly coupling the pump and driver.

Instructions for securely installing the coupling guard.

Requirements and procedures for lubricating pump bearings with oil or grease.

Overview of mechanical seal and packed stuffing box options and their connections.

Methods for priming the pump, with suction supply above or below the pump.

Essential checks and procedures to follow before and during pump startup.

Defines flow limits and permitted number of starts for the pump.

General considerations and warnings for safe pump operation.

Steps and precautions for safely shutting down the pump.

Procedures to perform final alignment check at operating temperature.

Outlines routine, three-month, and annual inspection tasks.

Procedures for bearing lubrication, oil changes, and grease requirements.

Maintenance procedures for mechanical seals and packed stuffing boxes.

Precautions, tools required, and steps for disassembling the pump.

Guidelines for inspecting parts before reassembly, including replacement criteria.

Step-by-step instructions for assembling pump components.

Common operational symptoms, their causes, and remedies.

Troubleshooting steps for alignment issues with the pump and driver.

Identifies common assembly problems and their solutions.

Information on how to obtain further relevant documentation.

Contact information for ITT regional offices worldwide.