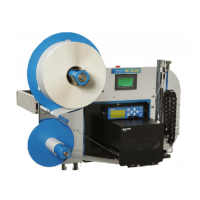

Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

User Interface Page 28

User Interface

4.3 Job Settings Screens

Map:

Note:

Can only be entered from an offline state

Screen Functionality

From this screen the user can switch jobs, thus recalling multiple job

settings at once. The system stores up to 60 jobs in non-volatile

memory.

From the Product Delay screen the time delay between product

detector trigger and application cycle can be adjusted. This delay can

be calculated by taking (5000 / linespeed in FPM) * the distance from

the product detector to peel blade edge in inches). This will yield the

delay in milliseconds to be entered on the screen. Some adjustment of

this value will be required to position the label on the product at the

desired location.

Only displayed if the system Apply Mode (

page 27) is set to 2 Tamps, 2

Tamp/Blows, or 2 Blows. Calculated the same as above, but with extra

time to allow the second label to print and be ready for the second

application. If the second label is not ready in time, a Timing

Violation warning will be given.

This setting controls the extension stroke time. If the auto-retract

sensor is not used, this is the only setting that controls the retract of

the tamp cylinder. If the Apply Mode (

page 27) is set for Blow, this will

be the duration of the blow cycle.

Only displayed if the system Apply Mode (

page 27) is set to 2 Tamps, 2

Tamp/Blows, or 2 Blows. This controls the second application extension

time.

In this screen, a waiting period between the cylinder returning home

and the next label printed can be adjusted. This delay can be useful for

allowing the tamp pad to settle, before a label is advanced from the

printer.

Loading...

Loading...