Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

System Modules Page 6

System Modules

2.0 System Modules

2.1 Mechanical SubSystem

Unwind P/N: 4600-605

Rewind P/N: 4600-606

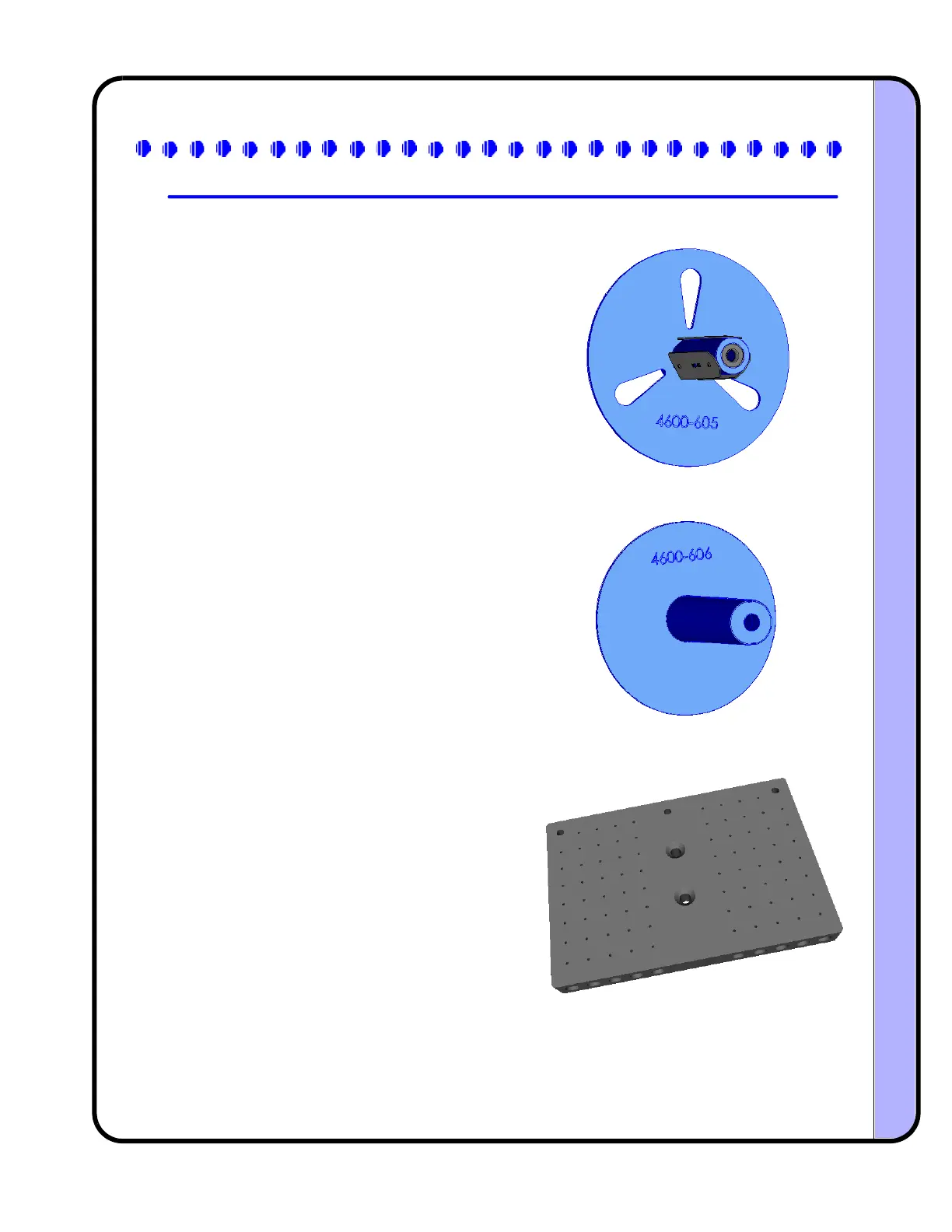

Tamp Pad P/N: 4600-610 Width x Length

The unwind is designed to capture supply

rollsupto14inchesindiameter,with3inch

cores. This subsystem uses a hub‐based fin

design to capture the supply roll without

need for an outer disk. This reduces

downtime in performing supply roll

changeouts, and allows small variations in

core

diameters.

The rewind is driven by a brushless DC

motor,whichgreatlyincreasesthelifeofthe

rewind system. This subsystem requires no

adjustments. There is no clutch on the

rewind,it usesthemotor’smagneticfieldto

develop holding torque. The rewind is belt

driven, using an automatic tensioner. This

belt

should be inspected for wear at the

recommendedserviceintervals.

The tamp pad captures the label from the

printer, andholds itundervacuumuntil the

time when the label is to be applied to the

product.Thereareseveralsizesoftamppads,

to accommodate a wide variety of label

dimensions. Each pad can be ported,

typicallyonce,fora

particularlabelsize.The

padvacuumholesarearrangedintocolumns,

whicharenotpunchedthrough.Whenapad

is ported, the proper columns are punched

out so that vacuum can draw the label onto

the pad. For most applications, the column

closest to the printer andthecolumn on

the

furthest end of the label (from the printer)

areported.

The tamp pad has provisions for mounting

the label present and auto retract sensors.

Thesesensorsmustbemounted flushto the

bottomofthepad,foroptimumsensing.

Loading...

Loading...