Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

System Modules Page 7

System Modules

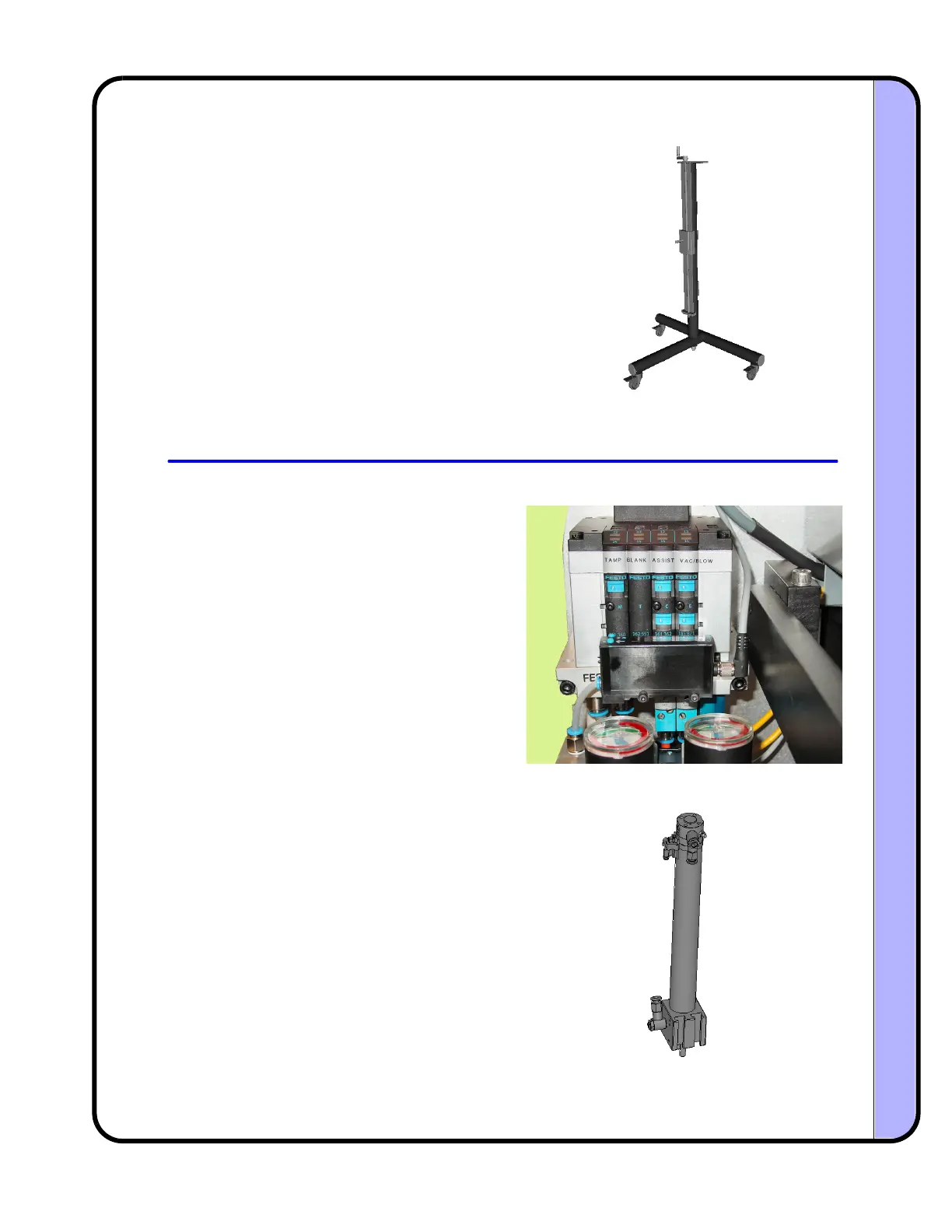

Stand P/N: 6160-329

2.2 Pneumatics SubSystem

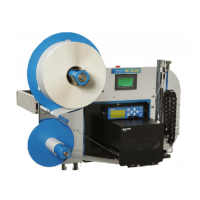

PAM (Pneumatic Air Manifold) P/N: 4600-701

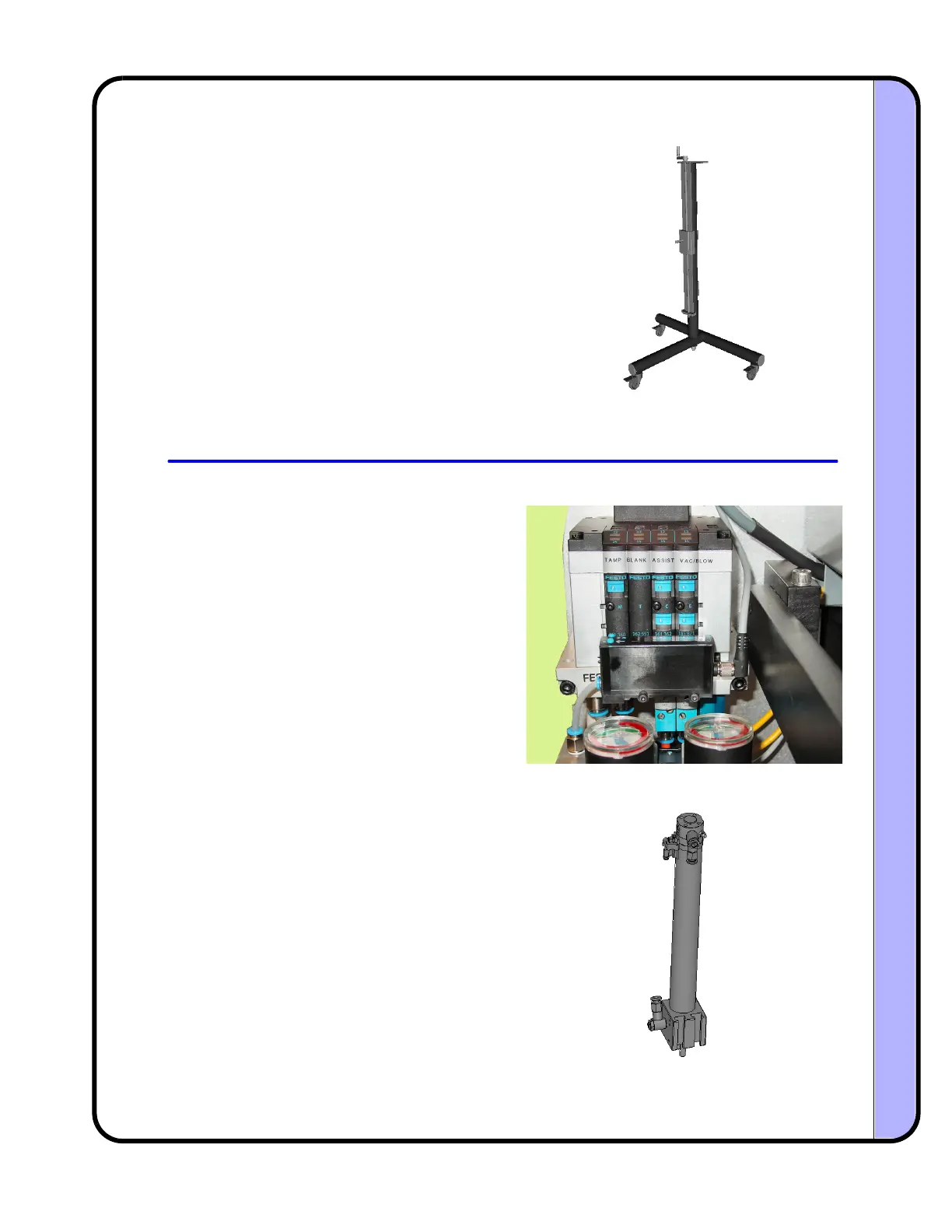

Tamp Cylinder P/N: 4600-743 (10 inch), 4600-745 (20 inch)

ThestandholdstheyokeassemblyofthePA/

4600orPA/6000,andallowsthesystemtobe

orientated in a variety of positions to suit

applicationrequirements.Thestandemploys

a hand crank to set vertical position, and a

series of mounting pointsfor items such as:

warning tower, remote

user interface, and

inletfilter/regulator.Thestandcontainsthree

lockable casters that prevent rolling

movement, as well as rotational movement.

The column of the stand is designed to be

rotated, which can help installations where

the front leg of the t‐base interferes with

existingequipment.

The air manifold controls the operation of

the tamp cylinder and the delivery of the

label from the printer to the product. The

manifoldhastwopressureregulators,onefor

tamp pressure and the other controls both

vacuum and blow. Two flow controls limit

the volume of air going to the

air assist and

blow valves. There are two pressure gauges

that monitor the pressure set by the

regulators. A pressure sensor monitors the

incomingairlevelanddisplaysitonadigital

readoutandbargraph.Anerroristriggeredif

the incoming pressure drops below the set

pointvalue.

The tamp cylinder employs a dual‐rod

designtoachieve very highspeedextension

and retraction, without rotation. The tamp

cylinder extension and retraction speed is

controlled by means of the tamp pressure

setting on the air manifold and the flow

controlsonthe cylinderbody.Anadjustable

air cushion on

the top of the cylinder

dampensthereturnenergy. Amagneticreed

switch, attached to the top of the cylinder,

detectsthe immediate returnof the cylinder

toitshomeposition.

Loading...

Loading...