4 - 10

Auxiliary Relief Valves (continued)

Dipper Ram

1 Prepare the Machine.

a Put the operator levers into neutral and lower the

gate lock lever. Start the engine and park the

machine on level ground. Operate the dipper out

and lower the boom to set the bucket on the

ground. Stop the engine. Release the hydraulic oil

tank pressure. (See Releasing Tank Pressure).

b Connect a 0 - 400 bar (0 - 6000 lb/in

2

) pressure

gauge and adaptor to port G1 on the hydraulic

pump (see view A on page 4 - 1).

2 If not already done, temporarily increase the pressure

setting of the MRV (see Auxiliary Relief Valves,

General, step 2).

3 Start the engine, lower the gate lock lever and run the

engine at maximum no-load speed in the S mode.

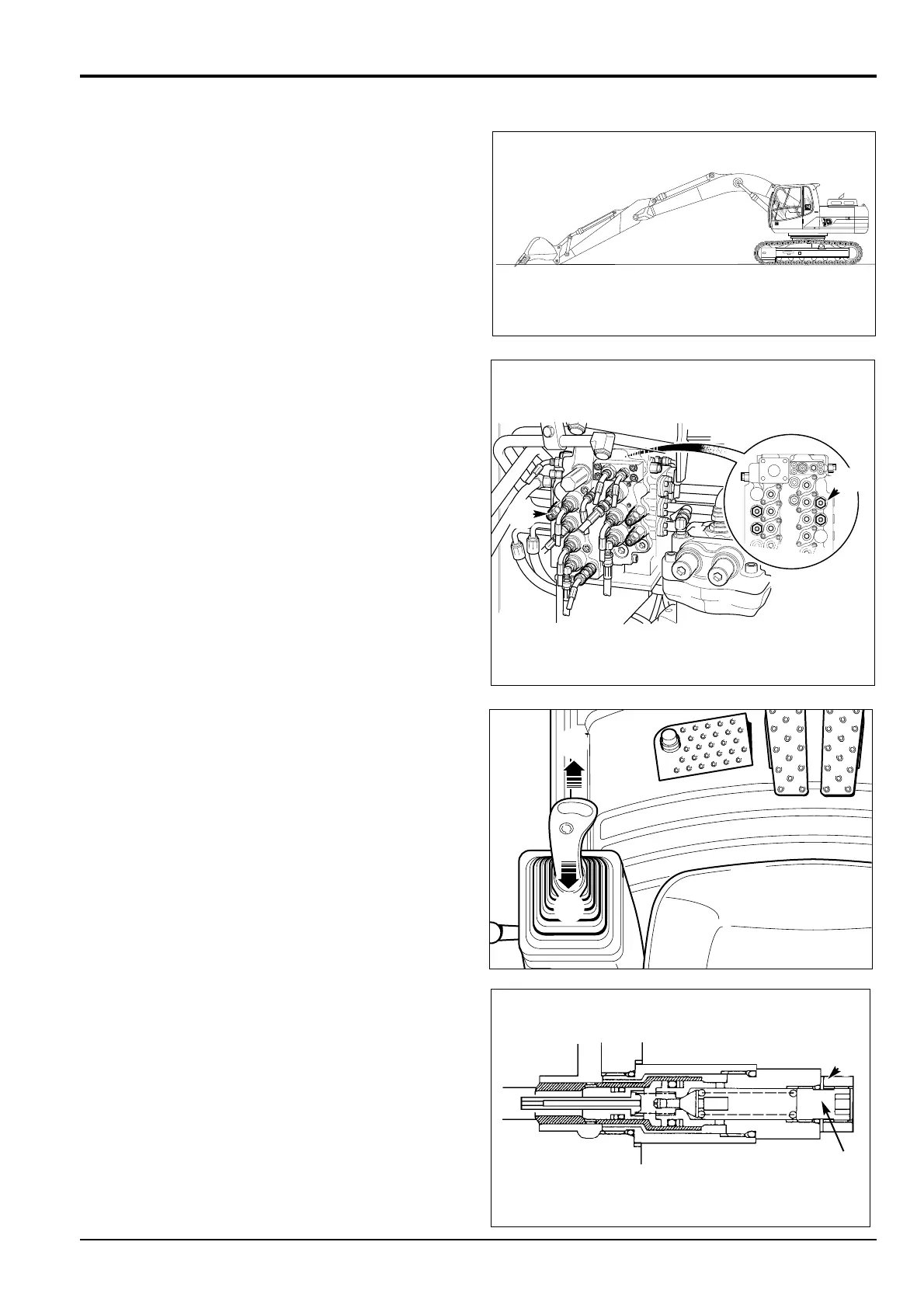

4 Pressure Adjustment

Note: For accurate setting, the pressure should be adjusted

up to the required level. Release lock nut X. Adjust setting

screw Y to indicate a pressure below the required level and

then bring the pressure back up for final setting. Tighten lock

nut X.

a Raise the boom to its full height.

b Move the dipper fully out and then continue to

operate the control lever, as at A.

c The pressure gauge reading (Dipper out) should be

compared to the technical data at the start of the

section. If it is outside the limits, adjust ARV F.

d Move the dipper fully in and then continue to

operate the control lever, as at B.

e Compare the pressure gauge reading to that stated

in the technical data section at the start of the

section. If it is outside the limits, adjust Auxiliary

Relief Valve G.

5 If further ARV tests are necessary carry out the relevant

procedures detailed in this section. If no further ARV

tests are required, restore the MRV pressure setting to

its original value (see Auxiliary Relief Valve, General,

step 3).

6 Stop the engine and release the hydraulic pressure (see

Releasing Tank Pressure). Remove the pressure gauge

and adaptor.

Section E Hydraulics

9803/6410

Section E

4 - 10

Issue 1

Pressure Testing

AA

BB

JS03511a

306490

312460

XX

YY

A296530

Loading...

Loading...