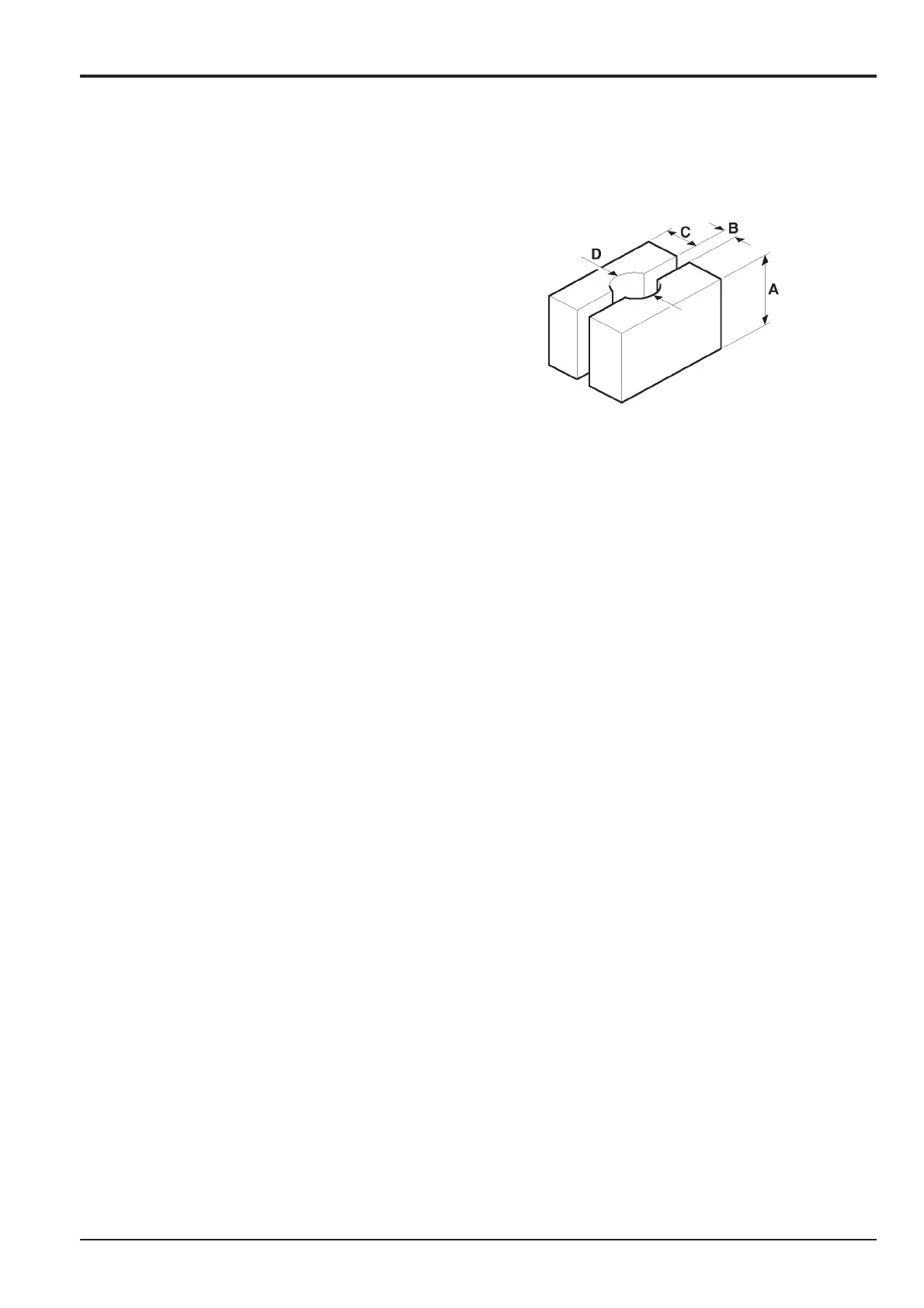

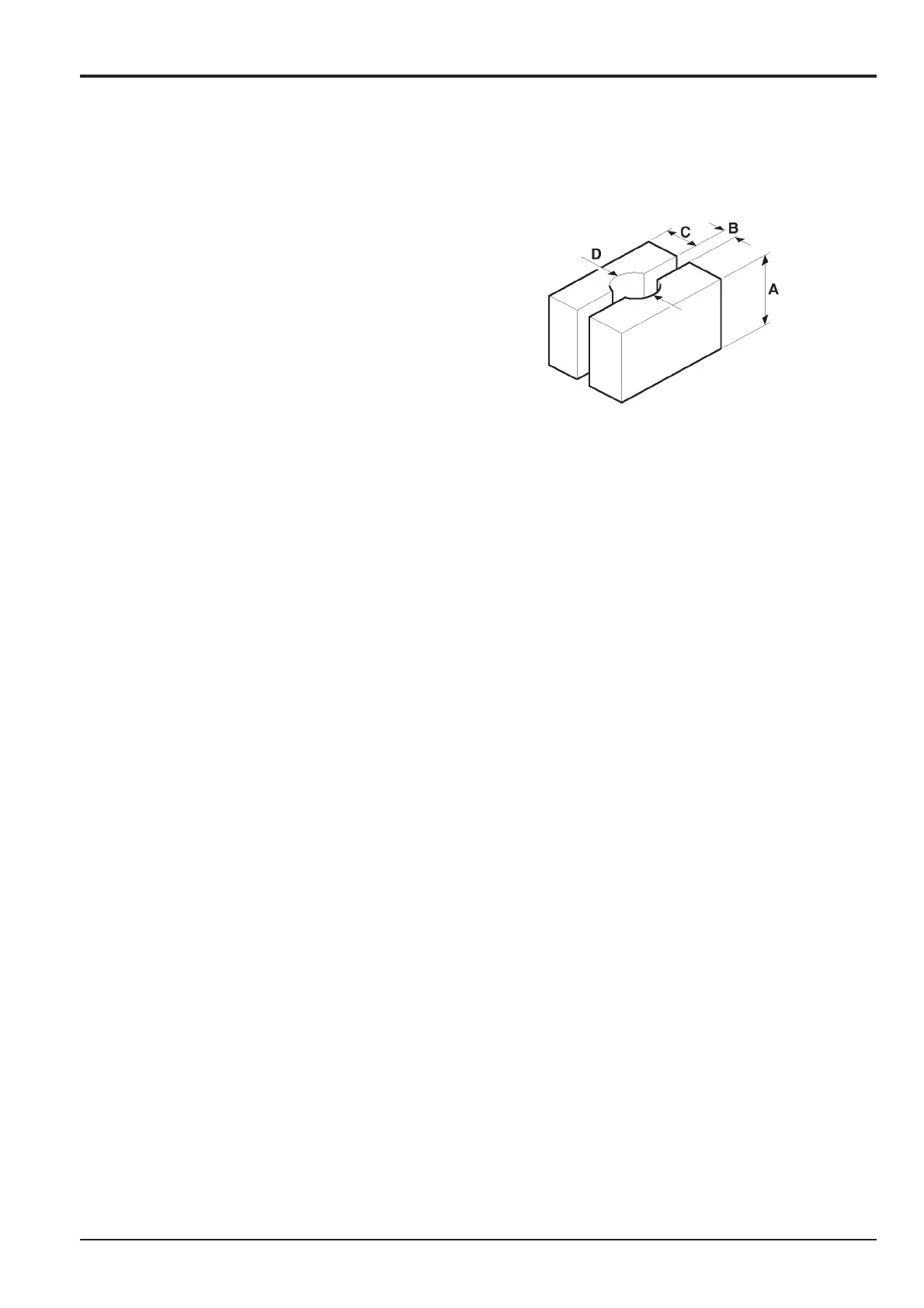

Key

A 70 - 100 mm (2.7 - 3.9 in)

B 3 - 6 mm (0.12 - 0.24 in)

C 30 - 40 mm (1.18 - 1.57 in)

D 22 mm (0.87 in)

34 - 4

Dismantling and Assembly (cont’d)

Note:

1 Ensure all work surfaces are clean.

2 Discard and renew all seals, ‘O’-rings and back-up

rings.

3 Lubricate all new seals and ‘O’-rings on assembly,

using a suitable grease or clean hydraulic oil and

ensure seals are firmly and correctly seated.

4 During dismantling, ensure all components are clearly

identified to assist assembly.

5 Handle components and sub-assemblies with care,

they are precision made and are easily damaged.

6 Prior to assembly, all components should be liberally

coated with hydraulic oil to ensure full movement

between moving parts.

7 Ensure screws and bolts are tightened to the correct

torque figures to prevent distortion of parts.

8 After dismantling, use a suitable solvent to clean all

components, dry using compressed air.

9 Torque tightening values in assembly procedures are for

threads lubricated with hydraulic oil.

11 To prevent surface damage when working on spools,

ensure they are encased in protective wooden blocks

as detailed opposite.

Section E Hydraulics

9803/6410

Section E

34 - 4

Issue 1

Control Valve

JS01510

Loading...

Loading...