6 - 4

Removal and Replacement (cont’d)

Replacement (cont’d)

4aInstall the covers over the motor.

b Check the amount of oil in the gearbox.

c Bleed air from the motor (see Motor Bleeding).

d If the traction motor has been dismantled and

serviced, carry out the functional tests detailed

under Testing later in this section.

e Install the drive sprocket (see Drive Sprocket,

Replacement, Section J).

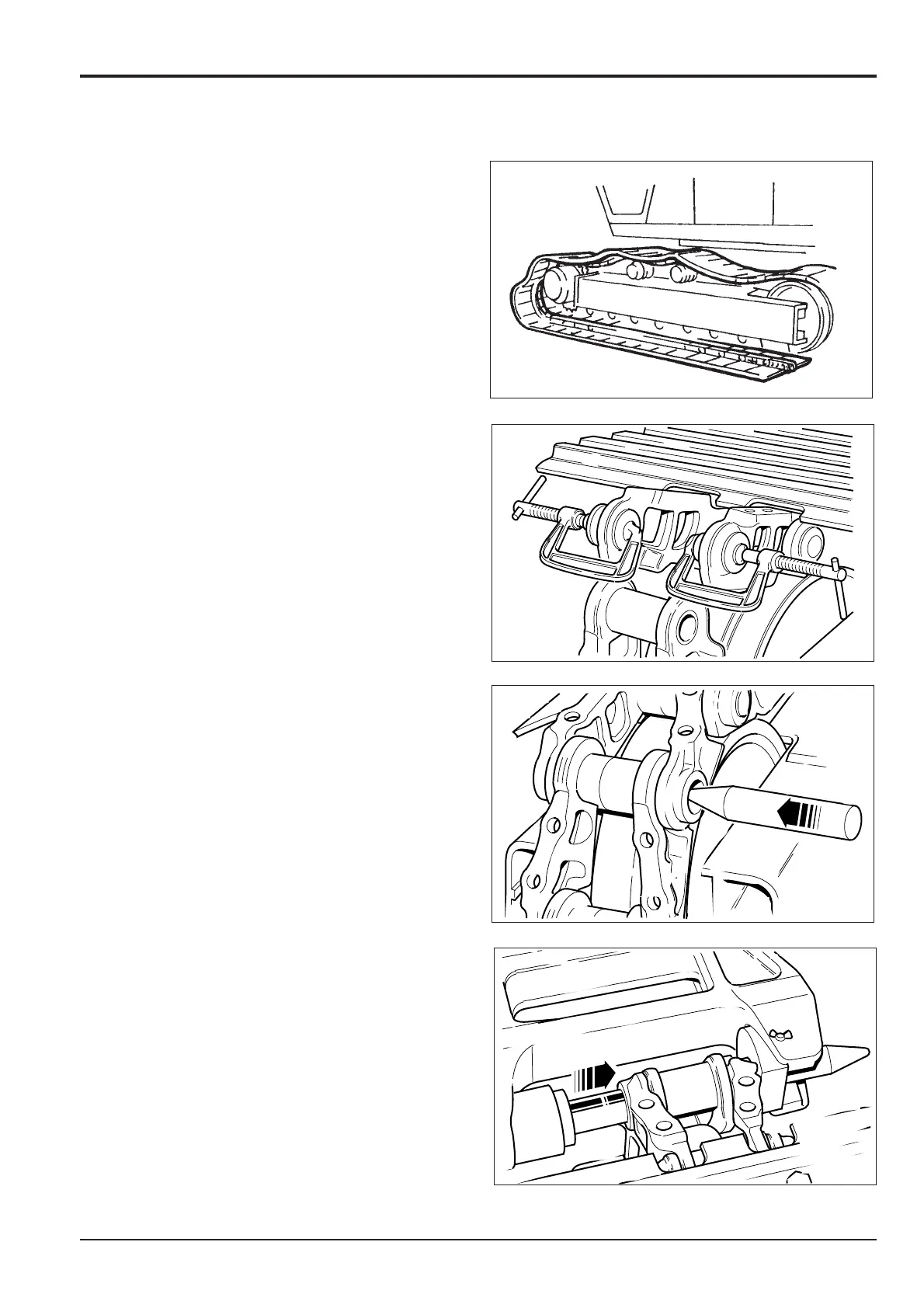

f Remove the wooden blocks.

g Position the lower frame on the track.

h Move the track link by reversing step 1 of Removal.

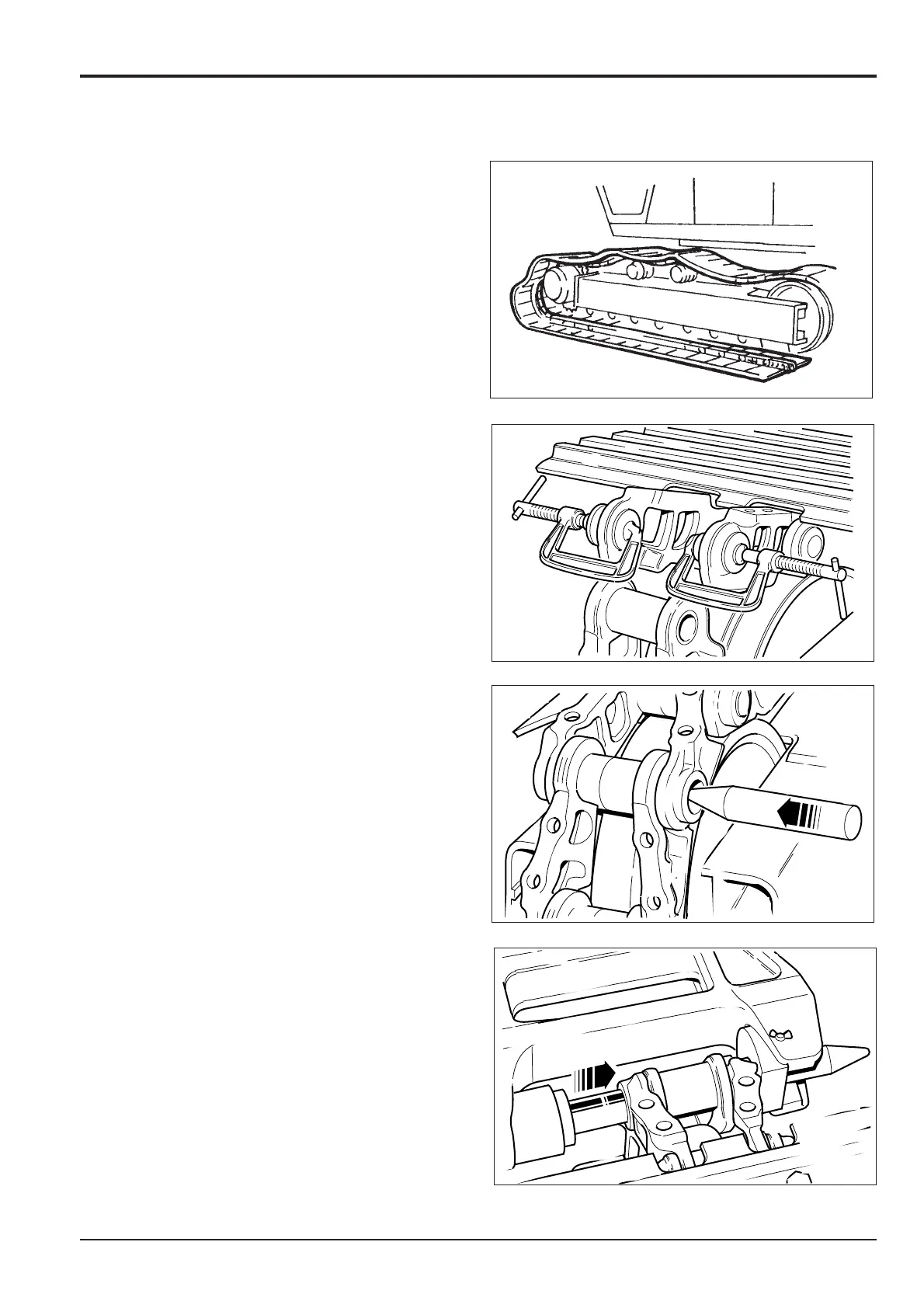

i Clean the seal ring housings in the chain link. Insert

the seal rings and clamp into position.

j Using a plastic hammer, tap the upper link down to

align holes.

Note: As the links overlap, the seal rings will be held in

position. Remove ‘G’ clamps.

k Insert the pointed guide pin from the inner face and

tap through its full length.

l Position a suitable hydraulic press so that its ram

aligns with the guide pin.

m Insert the master pin into its locating hole.

n Slowly operate the hydraulic ram and press the

master pin into position.

o Re-locate the track shoes and tighten the bolts (see

Checking Shoe Plate, Routine Maintenance,

Section 3).

Section F Transmission

9803/6410

Section F

6 - 4

Issue 1

Traction Motor/Reduction Gear

Loading...

Loading...