10 - 3

Other Measurements

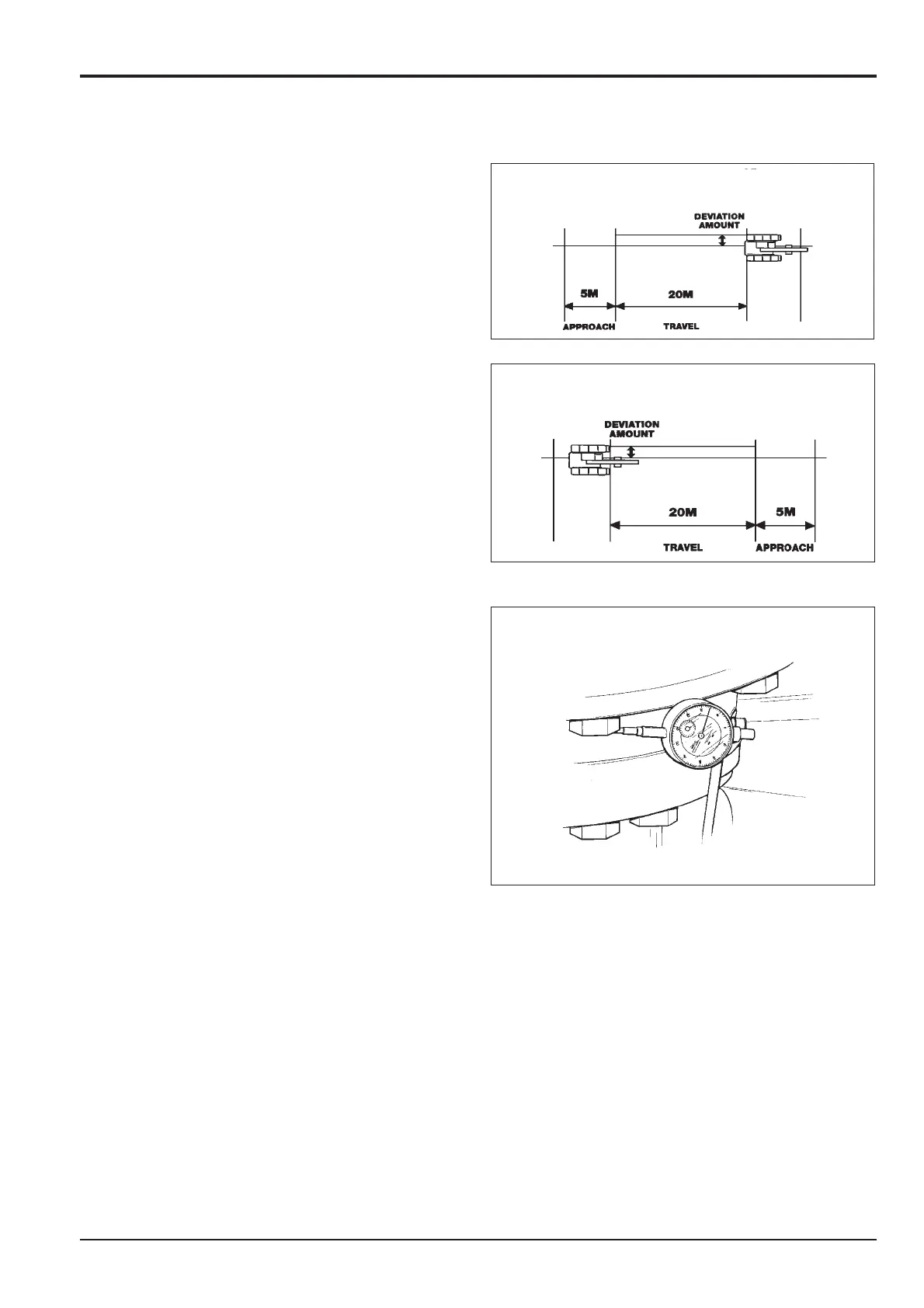

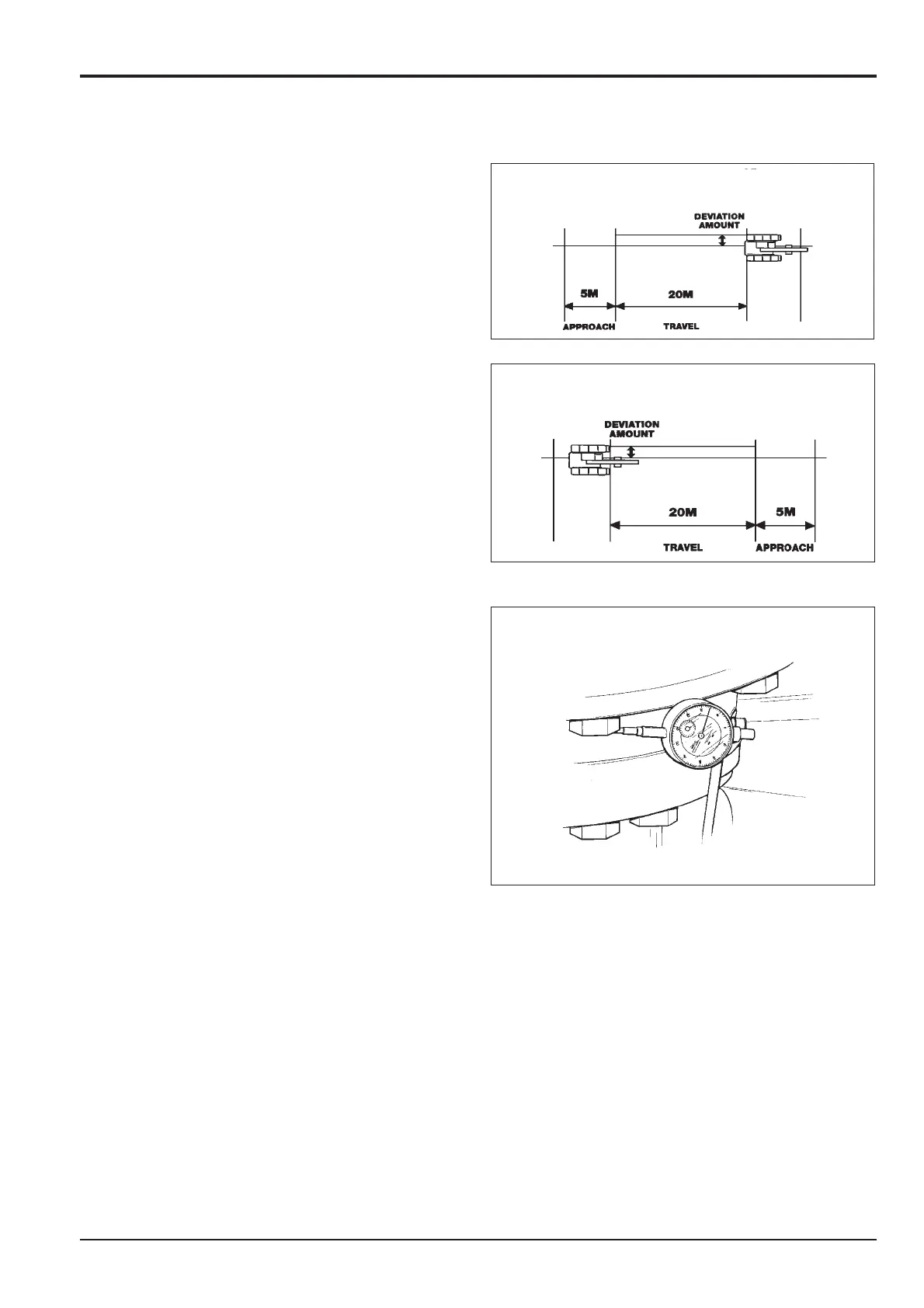

a Travel Linearity.

The conditions for checking are that the vehicle should

have an approach of 5 metres and a travel distance of

20 metres; measurement is of the amount of deviation

after 20 metres between the reference line and track

shoe.

Approach the reference line and adjust the position of

the track shoe/travel direction against the reference line

in the first 5 metres, then without adjusting, allow the

machine to travel 20 metres, then measure the

deviation, then complete the same procedure in

reverse.

b Slew Backlash.

1 The conditions for checking are to position the

bucket in the open position slightly above ground

and to stop the engine.

2 Gently push the bucket from the side and put a

mark on the ground, this becomes the 'Zero

Point'.

3 Then do the same for the opposite side of the

bucket and make a mark, the distance the

bucket has moved is the amount of

backlash.

Note: If the front attachment is pushed from side to side

repeatedly or if there is leakage or the attachments are

loose,

correct measurement will not be possible.

If the attachments are loose, position a dial gauge on the

turntable bearing and measure the movement here.

Section 3 Routine Maintenance

9803/6410

Section 3

10 - 3

Issue 1

Performance Evaluation

MEASUREMENT METHOD

MEASUREMENT METHOD

Loading...

Loading...