P/N 960-100189RA_Rev. A {EDP #148850} © 2009, Japan CashMachine Co., Limited

Troubleshooting VEGA™ SeriesBankNote Validator Appendix A

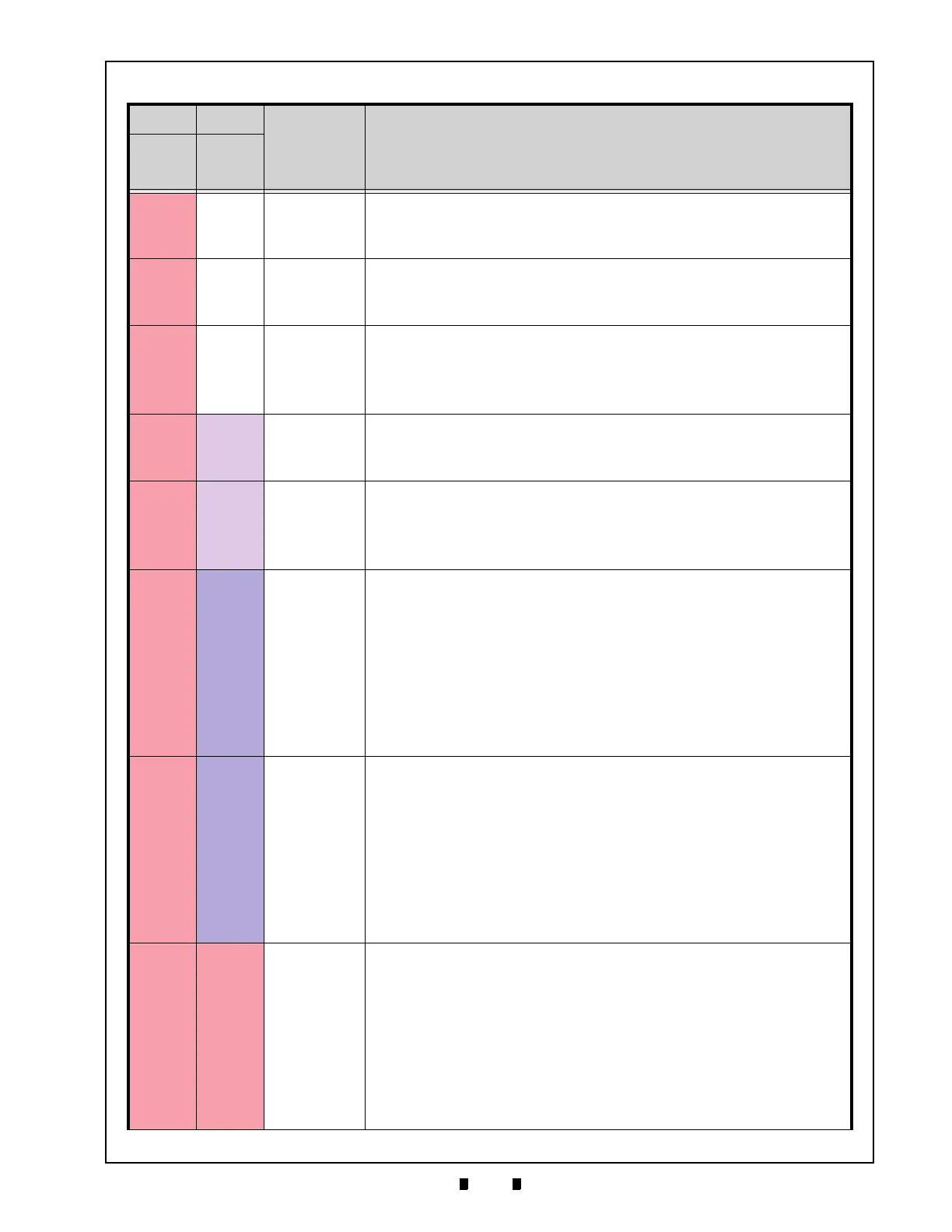

Red

3

(300)

White

3

(300)

Feed Motor Low

S

peed Problem

While operating the Feed Motor, no pulse input exist

s greater than the rated value.

[Solution] Check that the following parts are properly assembled and/or harness connected.

Feed Motor: SUB Board CN2 & CN3, CPU Board CN4.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

White

5

(300)

Feed Motor High

S

peed Problem

While operating the Feed Motor, no pulse input exist

s greater than the rated value.

[Solution] Check that the following parts are properly assembled and/or harness connected.

Feed Motor: SUB Board CN2 & CN3, CPU Board CN4.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

White

7

(300)

Feed Motor

L

ock-up Problem

While operating the Feed Motor, no pulse input exist

s greater than the rated value. (This error

occurs while initializing, or when a Banknote is at a transport position where it can not be

returned.)

[Solution] Check that the following parts are properly assembled and/or harness connected.

Feed Motor: SUB Board CN2 & CN3, CPU Board CN4.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

Purple

5

(300)

Stacker Motor

L

ock-up Problem

While operating the Stack Motor, no pulse input exists greater than the rated value.

[Solution] Check that the following parts are properly assembled and/or harness connected.

Stack Motor: SUB Board CN4 & CN3, CPU Board CN4.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

Purple

7

(300)

Stacker Motor

G

ear Problem

The Pusher Mechanism stays in its home position while the Stacker Motor is operating.

[Solution] Check that the following parts are properly assembled and/or harness connected,

a

nd clean all of the Sensors.

Stack Motor: SUB Board CN4 & CN3, CPU Board CN4,

Pusher Mechanism & Home Position

Sensor: SUB Board LED7 & PT2 &CN8, CPU Board CN8.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

Blue

2

(300)

Banknote

T

ransportation

Slips

An abnormal Banknote transportation error is d

etected when transporting or rejecting

Banknotes. The Transportation Slip Sensors do not detect continuous Banknotes being

transported according to the rated value.

[Solution] Check that the following parts are properly assembled and/or harness connected,

a

nd clean all of the Sensors.

Feed Motor: SUB Board CN2 & CN3, CPU Board CN4.

Stack-in Sensor: SUB Sensor Board (Upper) LED2, PS2

& CN1, SUB Board CN6 & CN8, CPU

Board CN7.

Cash Box Sensor: SUB Sensor Board (Upper) LED3, P

S3 & CN1, SUB Board CN6 & CN8, CPU

Board CN7.

Storage Flap Sensor: CPU Board F-SENS1.

Escrow Sensor: CPU Board LED

1 & P-SENS1.

Validation Sensor: Sensor Board (Upper) & Sensor Board (Lowe

r), LED1 & LED3 & PT1, LED2

& LED4 & PT2, LED5 & PT3.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

Blue

3

(300)

Transportation

T

imes out

An abnormal Banknote transportation error is d

etected when transporting or rejecting

Banknotes. The Transportation Locks-up or is running too slow. Sensors detect continuous

Banknotes being transported according to the rated value.

[Solution] Check that the following parts are properly assembled and/or harness connected,

a

nd clean all of the Sensors.

Feed Motor: SUB Board CN2 & CN3, CPU Board CN4.

Stack-in Sensor: SUB Sensor Board (Uppe

r) LED2&PS2&CN1, SUB Board CN6 & CN8, CPU

Board CN7.

Cash Box Sensor: SUB Sensor Board (Upper) LED3 &

PS3 & CN1, SUB Board CN6 & CN8,

CPU Board CN7.

Storage Flap Sensor: CPU Board F-SENS1.

Escrow Sensor: CPU Board LED

1&P-SENS1.

Validation Sensor: Sensor Board (Upper) & Sensor Board (Lowe

r), LED1 & LED3 & PT1, LED2

& LED4 & PT2, LED5 & PT3.

If the error is not resolved, change the above related part or parts.

Red

3

(300)

Red

3

(300)

Abnormal

T

iming Response

(Transport,

Reject

, other)

Sensors detect Banknotes remain in path or

none exist during abnormal timing.

[Solution] Check that the following parts are properly assembled and/or harness connected,

a

nd clean all of the Sensors.

Stack-in Sensor: SUB Sensor Board Upper LED2

& PS2 & CN1, SUB Board CN6 & CN8, CPU

Board CN7.

Box Sensor: SUB Sensor Board (Upper) LED3 &

PS3 & CN1, SUB Board CN6 & CN8, CPU

Board CN7.

Store Flap Sensor: CPU Board F-SENS 1.

Escrow Sensor: CPU Board LED

1 & P-SENS1.

RC Flap Sensor: CPU Board F-SENS2.

Side Sensor: CPU Board SIDE-LED & SIDE

Pusher Mechanism Home Position Sensor: SUB Board LED7

& PT2 & CN8, CPU Board CN8

Validation Sensor: Sensor Board (Upper) & Sensor Board (Lower) LED1 & LED3 & PT1, LED2

& LED 4& PT2, LED5 & PT3.

If the error is not resolved, change the above related part or parts.

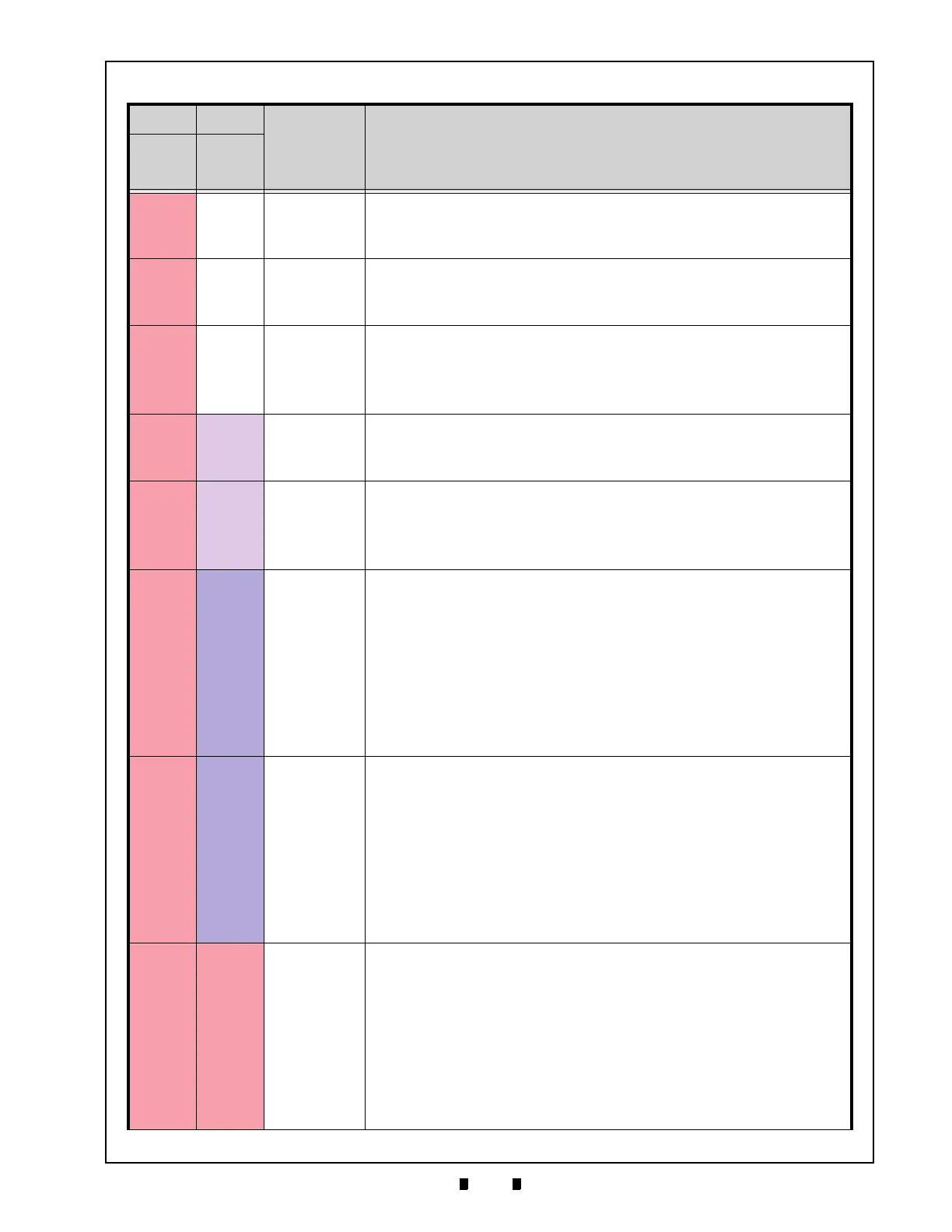

Table A-2 Error Codes (Continued)

on-line off-line

Error Causes and Solutions

Color

Flashes

(msec)

Color

Flashes

(msec)

Loading...

Loading...