24

15.0 Lubrication schedule and general maintenance

Regularly scheduled maintenance is crucial to ensure a long service life for your machine. The schedule below shows

general cleaning, lubrication points and coolant replacement information for the ZX Series Lathes. Push stop button

and power off before lubricating. Follow local regulations for disposal of used coolant/lubricants. Minimize direct

skin contact with lubricants and coolants, and wear eye protection when pouring coolant in case of splash.

Mobile DTE® Oil Heavy Medium is recommended for the SAE-20W machine oil.

If the brand of oil is ever changed, it is recommended that you flush and clean the reservoir first to prevent any

compatibility issues.

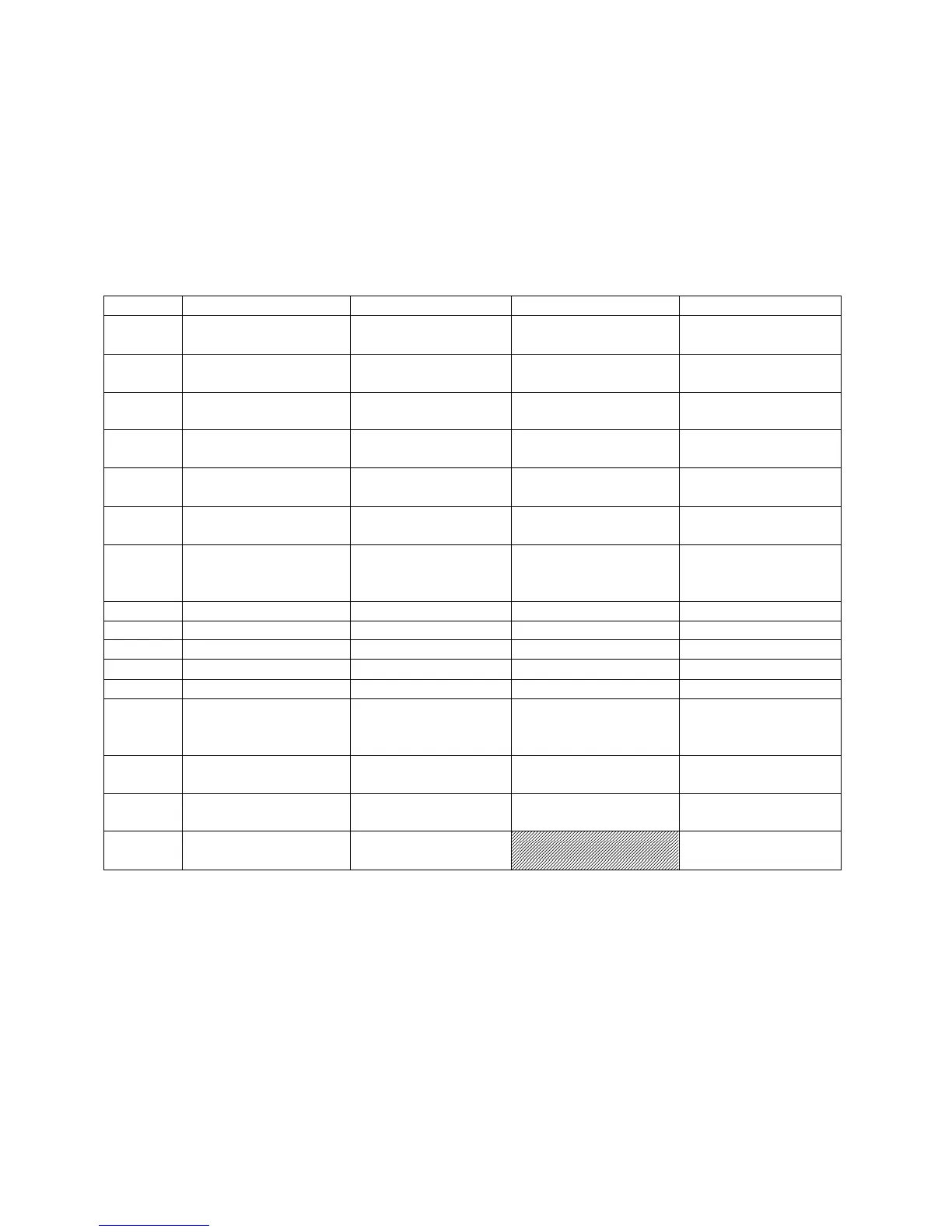

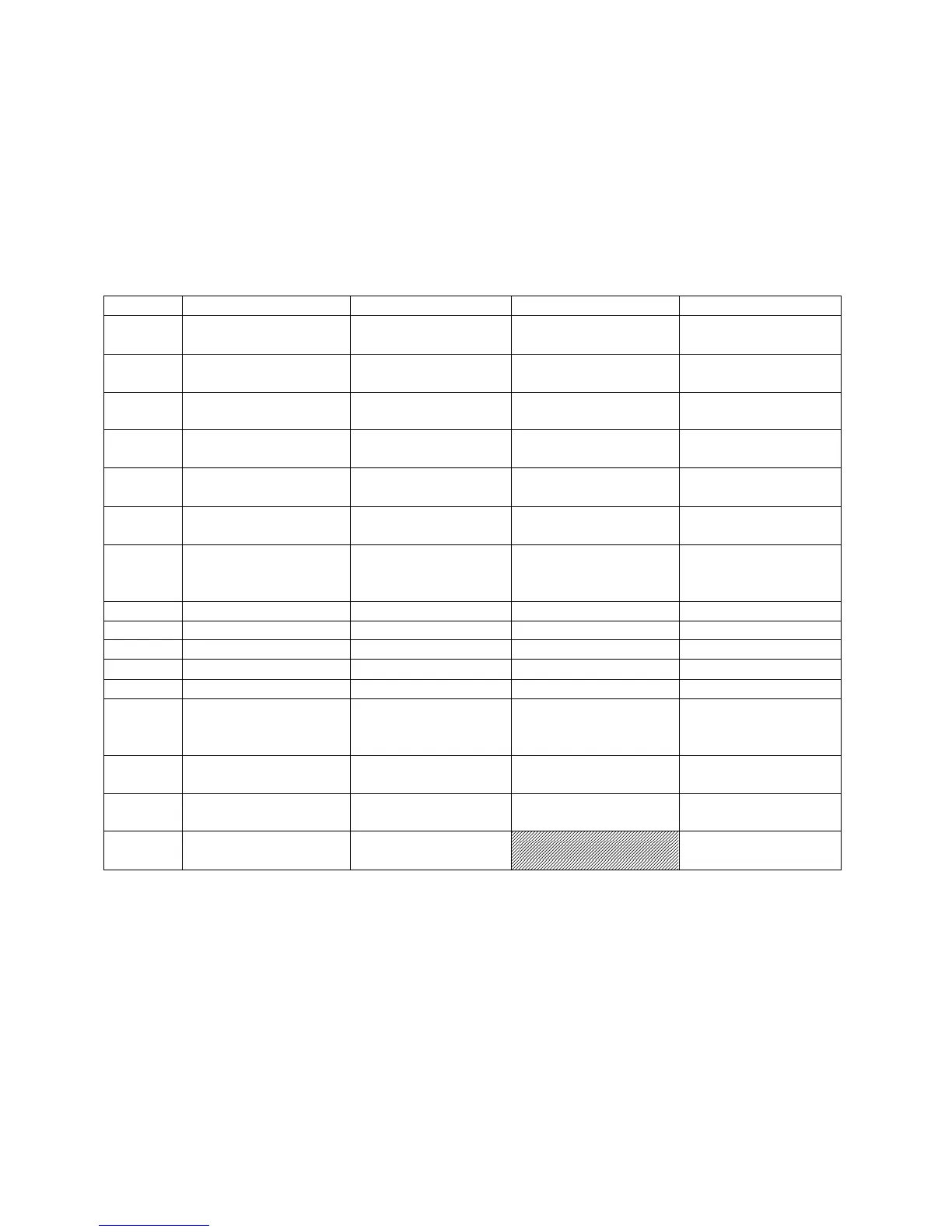

Table 1

Section Element Action Lubricant Frequency

8.3 Chuck Grease jaws and scroll #2 lithium tube grease periodically

8.3

Spindle/cam locks/

chuck body

light coat of oil SAE-20W machine oil periodically

All exposed metal

surfaces

light coat of oil SAE-20W machine oil frequently

9.0 Headstock Drain and fill SAE-20W machine oil

- after 30 days,

- every 2 months

9.0 Gearbox Drain and fill SAE-20W machine oil

- after first 3 months,

- every 6 months

9.0 Apron and Saddle Drain and fill SAE-20W machine oil

- after first 3 months,

- then annually

9.0

Leadscrew; Feed Rod;

Spindle Direction

Control Axle

Fill at ball oilers SAE-20W machine oil

daily (1 or 2 times per

shift)

Travel Setting Rod Fill at (1) ball oiler SAE-20W machine oil as needed

9.0

Cross slide Fill at (2) ball oilers SAE-20W machine oil daily

9.0

Compound rest Fill at (2) ball oilers SAE-20W machine oil daily

9.0

Tailstock Fill at (1) ball oiler SAE-20W machine oil daily

9.0 Anti-dust felt on v-ways Clean kerosene Inspect weekly

10.0 Coolant reservoir

(follow coolant

manufacturer’s

directions)

Coolant of choice,

approx. 4 gallons

(follow coolant

manufacturer’s

directions)

14.10 Steady Rest

Lubricate finger shafts

and contact points

Lead-based grease before each use

14.11 Follow Rest

Lubricate finger shafts

and contact points

Lead-based grease before each use

14.6 V-belts

Inspect and tighten if

needed

periodically

Loading...

Loading...