5

GHB-1330/ GHB-1340A:

Spindle taper MT-5

Spindle nose DIN 55029 D1-4

(Camlock)

Hole through spindle ∅38 mm

Spindle speeds…8 70-2000 rpm

Tailstock ram travel 95mm

Tailstock quill diameter 32mm

Tailstock taper MT-3

Cross slide travel 160mm

Top slide travel 68mm

Tool size max 16 x 16 mm

Lead screw pitch 4mm

Longitudinal feeds..36 0,04–0,8mm/r

Cross feeds…36 0,01–0,2mm/r

Metric threads...23 0,45–10mm/r

Inch threads…32 3,5 – 80 TPI

Mains 400V ~3L/PE 50Hz

Output power 1,5 kW (2 HP) S1

Reference current 4 A

Extension cord (H07RN-F): 4x1,5²

Installation fuse protection 16A

4.2 Noise emission

Acoustic pressure level

(according to EN ISO 11202):

Idling at maximum speed

LpA 78,4 dB(A)

The specified values are emission

levels and are not necessarily to be

seen as safe operating levels.

As workplace conditions vary, this

information is intended to allow the

user to make a better estimation of the

hazards and risks involved only.

4.3 Content of delivery

GHB-1330:

Machine cabinet stand

Chip tray

Splash guard

160mm 3-jaw universal chuck

300mm faceplate

Four way tool post

Steady rest

Follow rest

Set of change gears

2 pcs. MT3 fixed centres

MT3/MT5 centre sleeve

Threading dial

Operating tools in tool box

Oil can

Lifting hook

Operating manual

Spare parts list.

GHB-1340A:

Machine cabinet stand

Chip tray

Splash guard

160mm 3-jaw universal chuck

200mm 4-jaw independent chuck

300mm faceplate

Four way tool post

Steady rest

Follow rest

Set of change gears

2 pcs. MT3 fixed centres

MT3/MT5 centre sleeve

Threading dial

Operating tools in tool box

Oil can

Lifting hook

Operating manual

Spare parts list.

4.4 Machine description

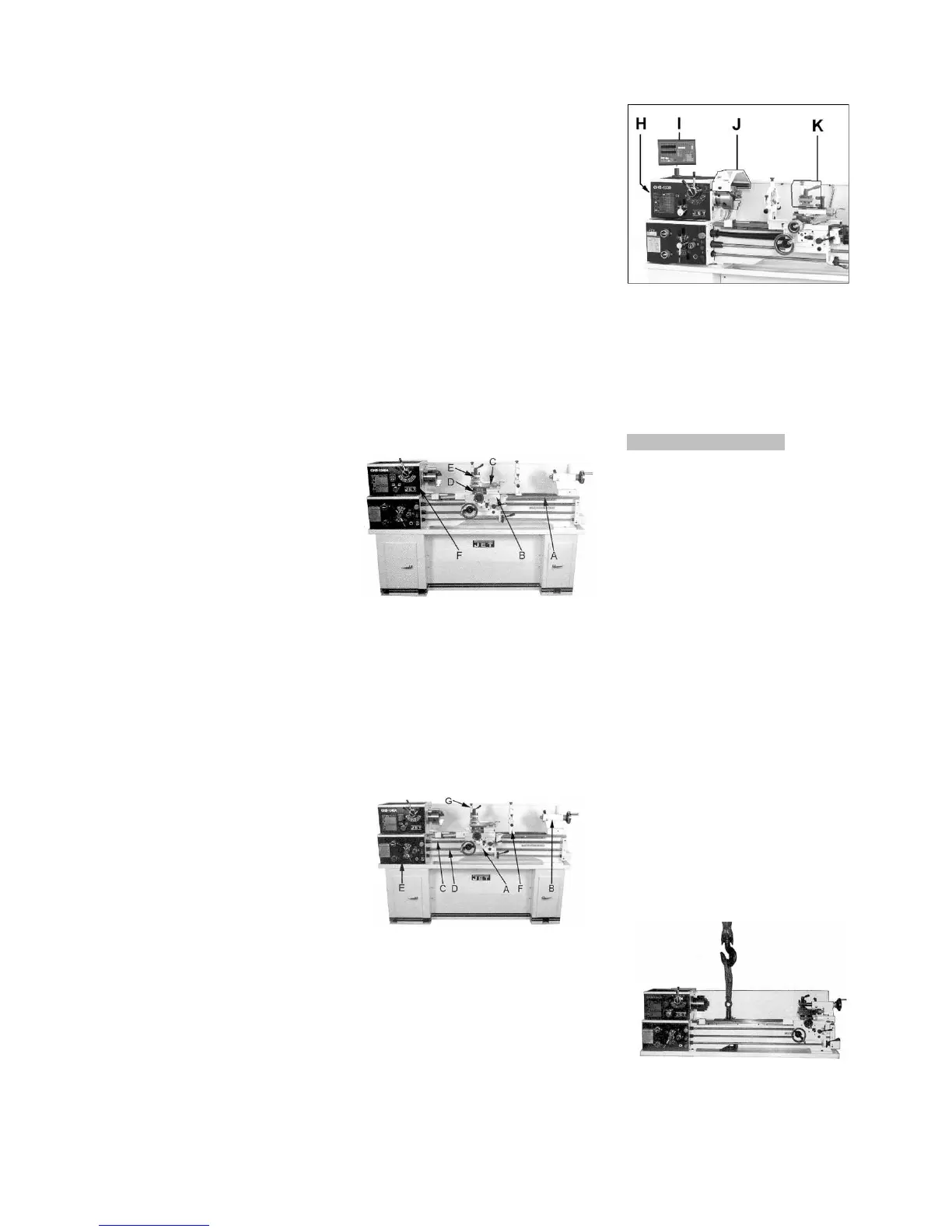

Fig 1

A….Lathe bed

B….Carriage

C….Top slide

D….Cross slide

E….Four-way tool post

F….Headstock

Fig 2

A….Apron

B….Tailstock

C….Lead screw

D….Feed rod

E….Gear box

F….Steady rest

G….Follow rest

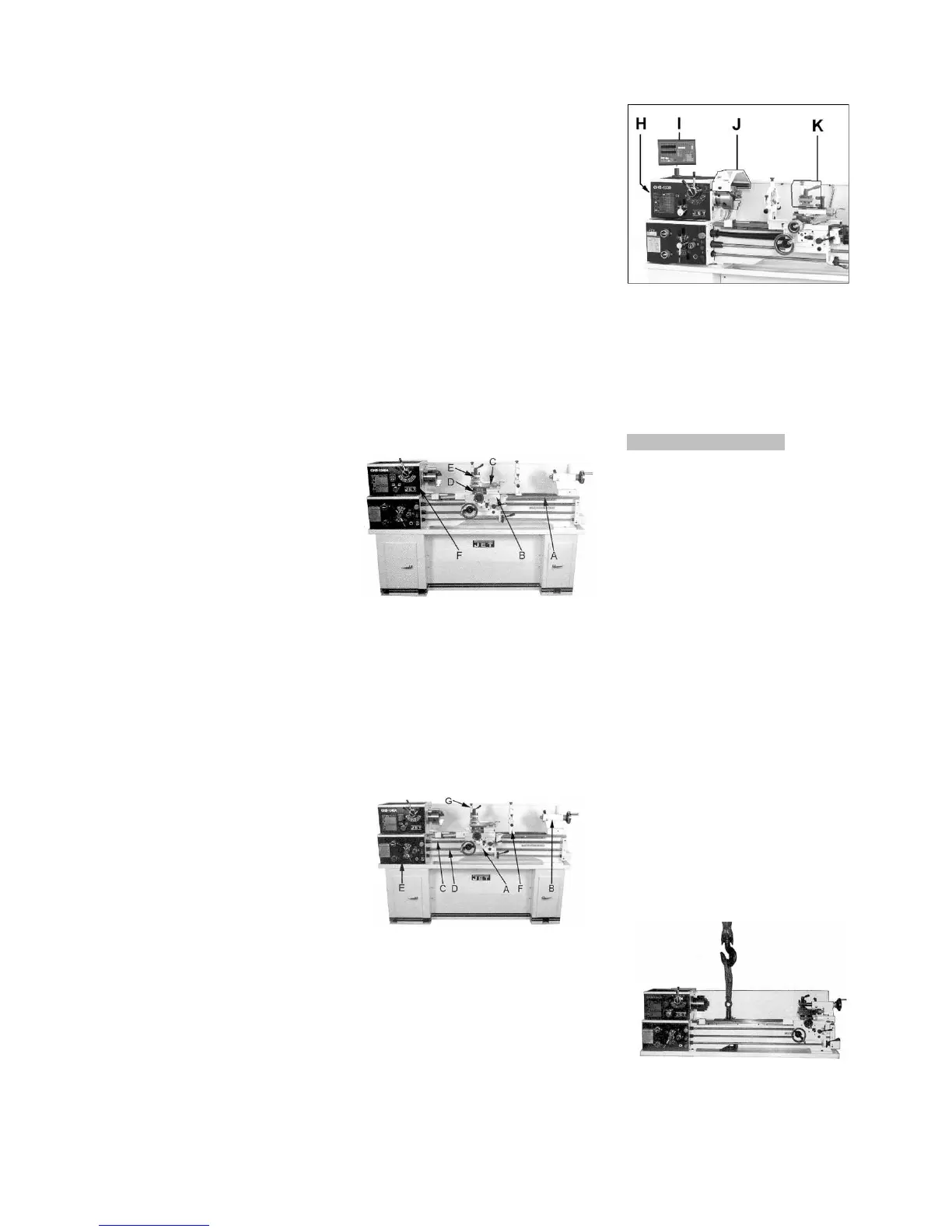

Fig 3

H….Pulley cover

I…...3-axis digital readout (option)

J.….Chuck guard

K….Tool post guard

5. Transport and start up

5.1 Transport and installation

The machine will be delivered in a

closed crate.

For transport use a forklift or hand

trolley. Make sure the machine does

not tip or fall off during transport.

The machine is designed to operate in

closed rooms and can be bolted to the

floor.

5.2 Assembly

If you notice transport damage while

unpacking, notify your supplier

immediately. Do not operate the

machine!

Dispose of the packing in an

environmentally friendly manner.

Clean all rust protected surfaces with

petroleum, diesel oil or a mild solvent.

Unbolt the lathe from the shipping

crate bottom.

Move the carriage and tailstock to the

tailstock end of the bed.

Assemble lifting hook (parts fastened

to the crate bottom) to lift the lathe

(see Fig 4)

Fig 4

Loading...

Loading...