13

Cord length Wire gauge (AWG)

0 – 25 ft. 16

25- 50 ft. 14

Table 3

Important: Make certain the receptacle in question

is properly grounded. If you are not sure, have a

registered electrician check the receptacle.

8.0 Adjustments

Note: Your miter saw was adjusted by the

manufacturer. However, during shipment slight

misalignment may have occurred. Check the

following settings and adjust if necessary prior to

using this miter saw.

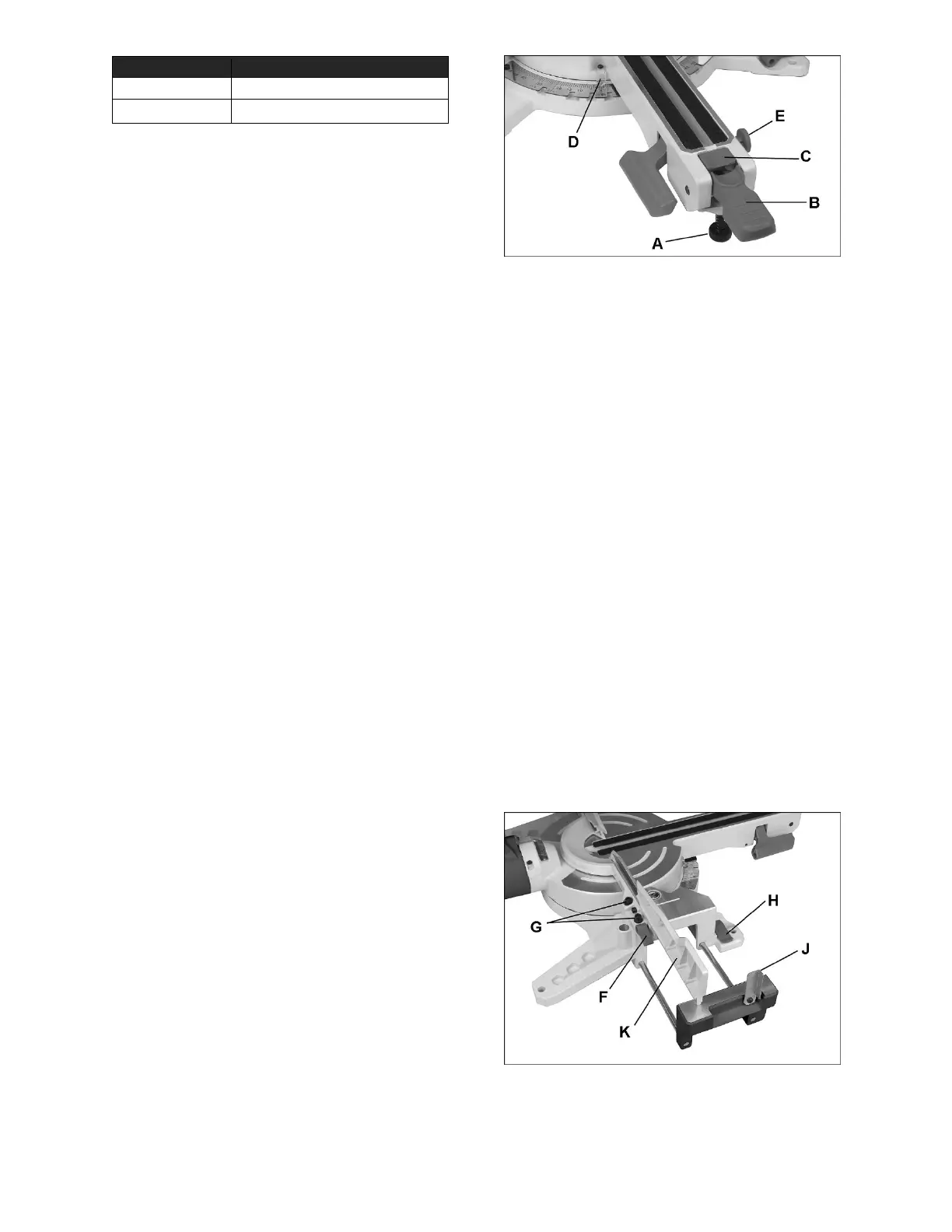

8.1 Support foot

The foot (A, Figure 8-1) can be turned in or out to

adjust its height. It is designed to provided support

for the miter table when locking handle is pushed

down or when cutting head is brought forward for

slide-cutting. The foot should be adjusted to contact

surface of bench or worktable.

8.2 Miter angle setting

The miter scale shows miter angles from 0° to 52°

to the left, and 0° to 60° to the right.

To set miter angle:

1. Lift up on miter lock handle (B, Figure 8-1) to

unlock table.

2. Press and hold release button (C) and use miter

lock handle to push cutting arm until desired

degree aligns with angle indicator (D).

3. Push down miter lock handle (B) to lock the

position.

Note: The release button (C) can be continuously

engaged to bypass the stops. This is convenient

when frequent and quick adjustment of miter angles

is needed.

1. Push down release button (C) and push in pin

(E). Release button is now continuously

engaged.

2. Grasp handle (B) and freely rotate cutting arm.

3. Press release button (C) again to disengage

pin.

Figure 8-1: selecting miter angles

8.2.1 Miter positive stop selection

The miter saw table has preset stops for quick and

accurate positioning at common angle settings of 0°,

15°, 22.5°, 31.6°, and 45° left and right; and 60°

right.

1. Lift up on miter lock handle (B, Figure 8-1) to

unlock table.

2. Press release button (C) and move table with

handle (B). As scale indicator approaches the

desired degree, release the button (C). The

table will engage the next positive stop.

3. Push down miter lock handle (B) to lock the

position.

8.2.2 Miter scale indicator alignment

1. Rotate table to the 0° stop.

2. If indicator (D, Figure 8-1) does not align with

zero on scale, loosen screw and adjust indicator

to 0° mark. Retighten screw.

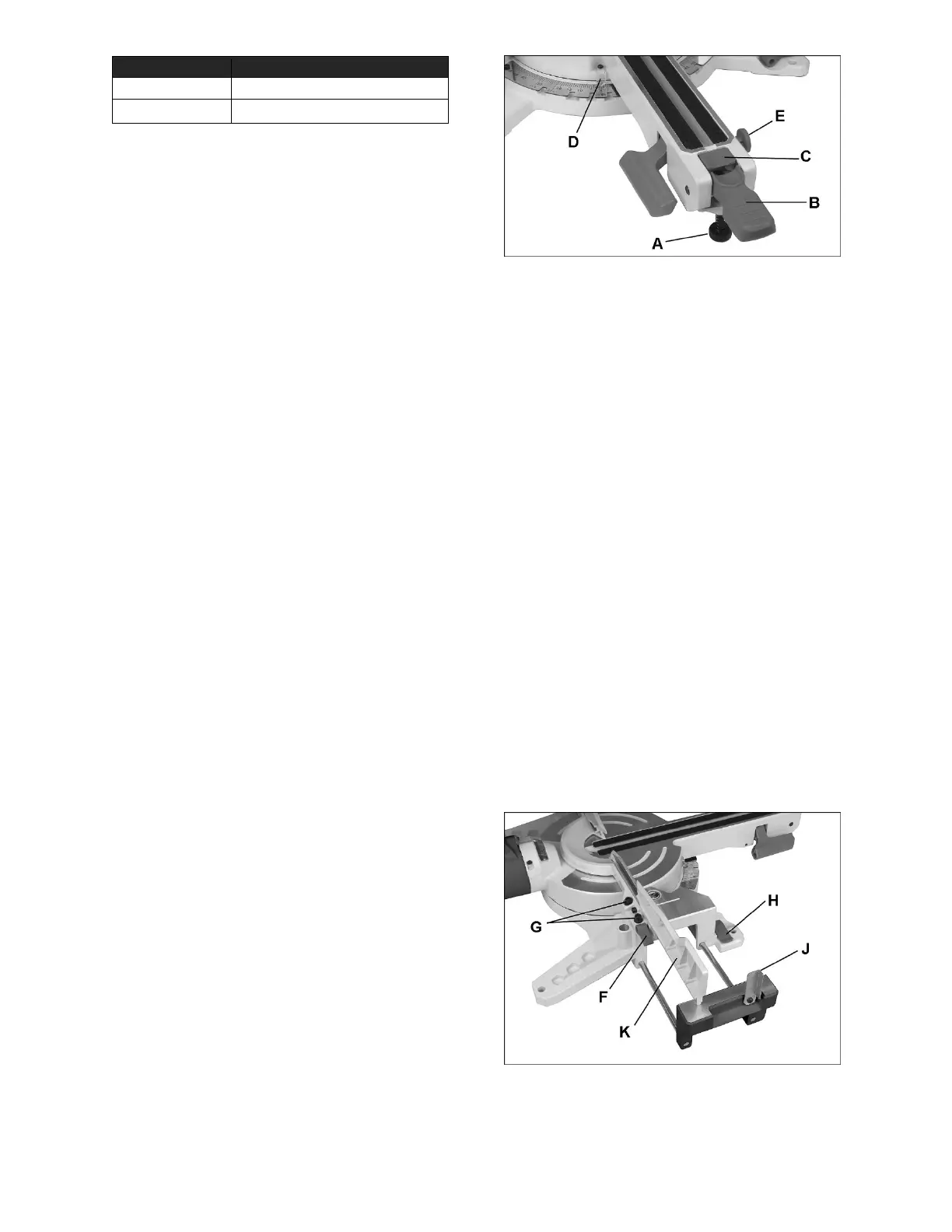

8.3 Table extensions and work stop

Pull up lock handle (H, Figure 8-2) and slide table

extension outward, as shown. Push down lock

handle to secure position.

Raise workstop (J) for quick positioning of stock

when cutting multiple pieces of equal length.

Figure 8-2

Loading...

Loading...