9

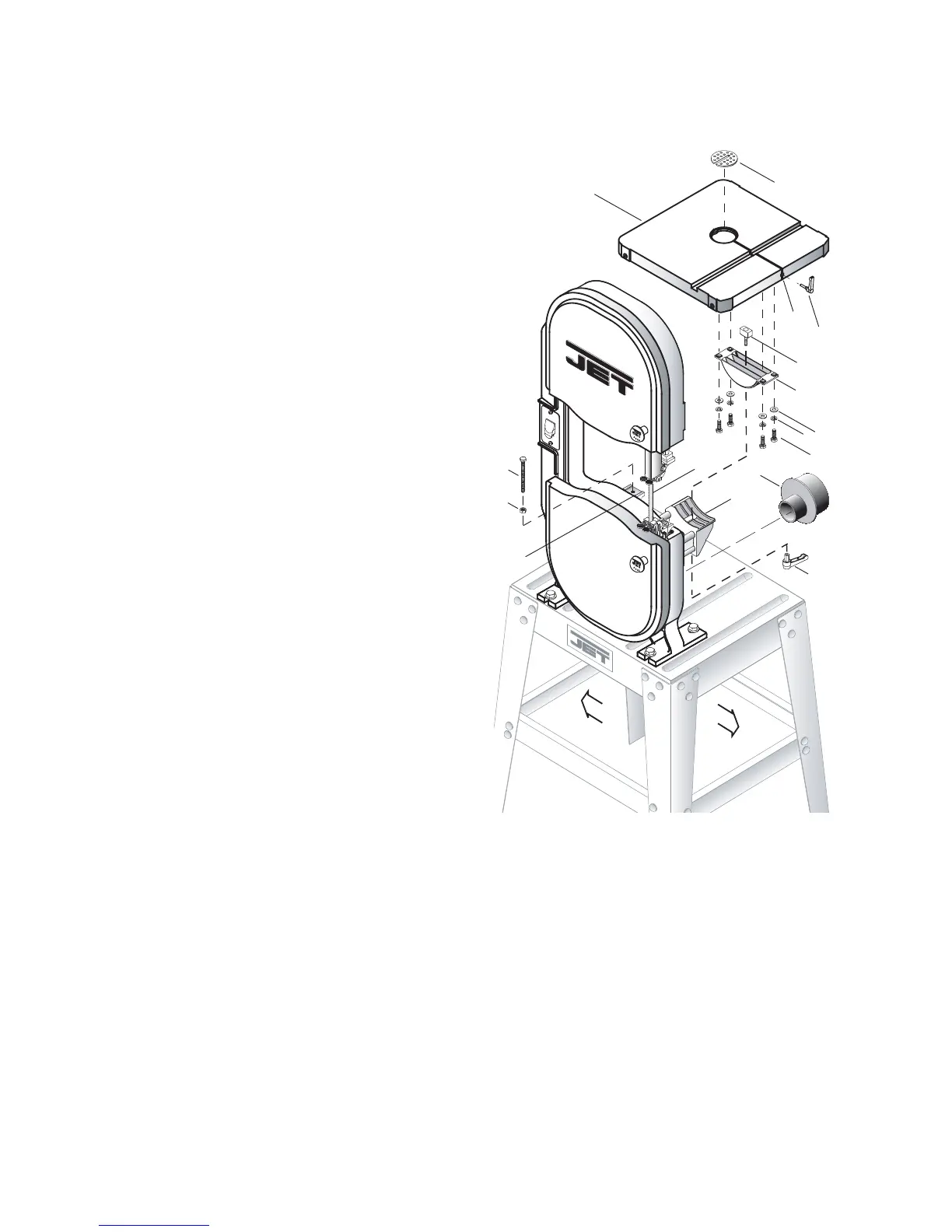

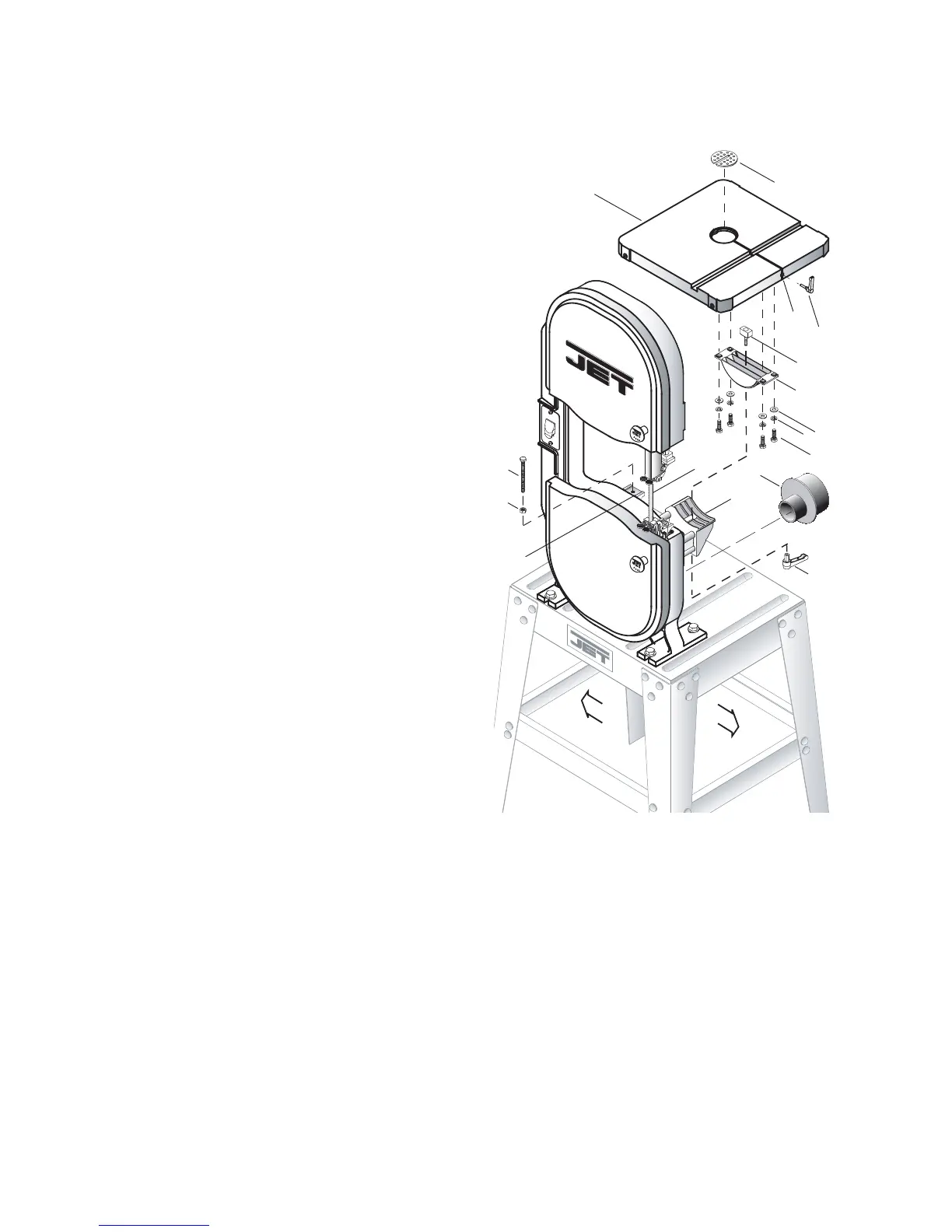

Table Assembly

For this section, refer to Figure 3.

90º Table Stop

1. Thread the M6 hex nut (R) approximately half

way onto the M6x70 hex cap screw (M). Then

thread the screw half way into the bracket (A

B

).

Adjustment will be made later.

Trunnion Installation

2. Position the trunnion (C) on top of the trunnion

support bracket (C

C

). The scale on the trun-

nion must be on the same side as the indicator

arrow on the bracket.

3. Place the clamp shoe (C

A

) through the middle

slot at the top of the trunnion (C), inserting the

screw through the slotted opening at the

bottom of the trunnion and through the support

bracket (C

C

).

4. Thread the lock handle (C

B

) onto the screw

protruding through the bottom of the support

bracket (C

C

). Adjust the trunnion (C) to 0º, then

secure by tightening the lock handle (C

B

).

Table Installation

5. Remove the insert (B

A

) and pin (B

B

) from the

table (B).

6. Maneuver the table (B) to allow the saw

blade (A

A

) to pass through the slot (B

C

) to the

round opening in the center.

7. Orient the table (B) as shown.

8. Line up four threaded mounting holes

underneath the table (B) with the four mount-

ing through-holes on the trunnion (C).

9. Secure with four each M8x20 hex cap

screws (O), M8 lock washers (S) and M8xØ18

flat washers (T).

10. Tighten the screws (O) with a 13mm wrench.

Right

T

C

C

A

C

B

S

O

B

A

B

B

B

D

C

C

B

C

Left

A

A

M

R

A

B

Figure 3

Loading...

Loading...