18

2.0-1

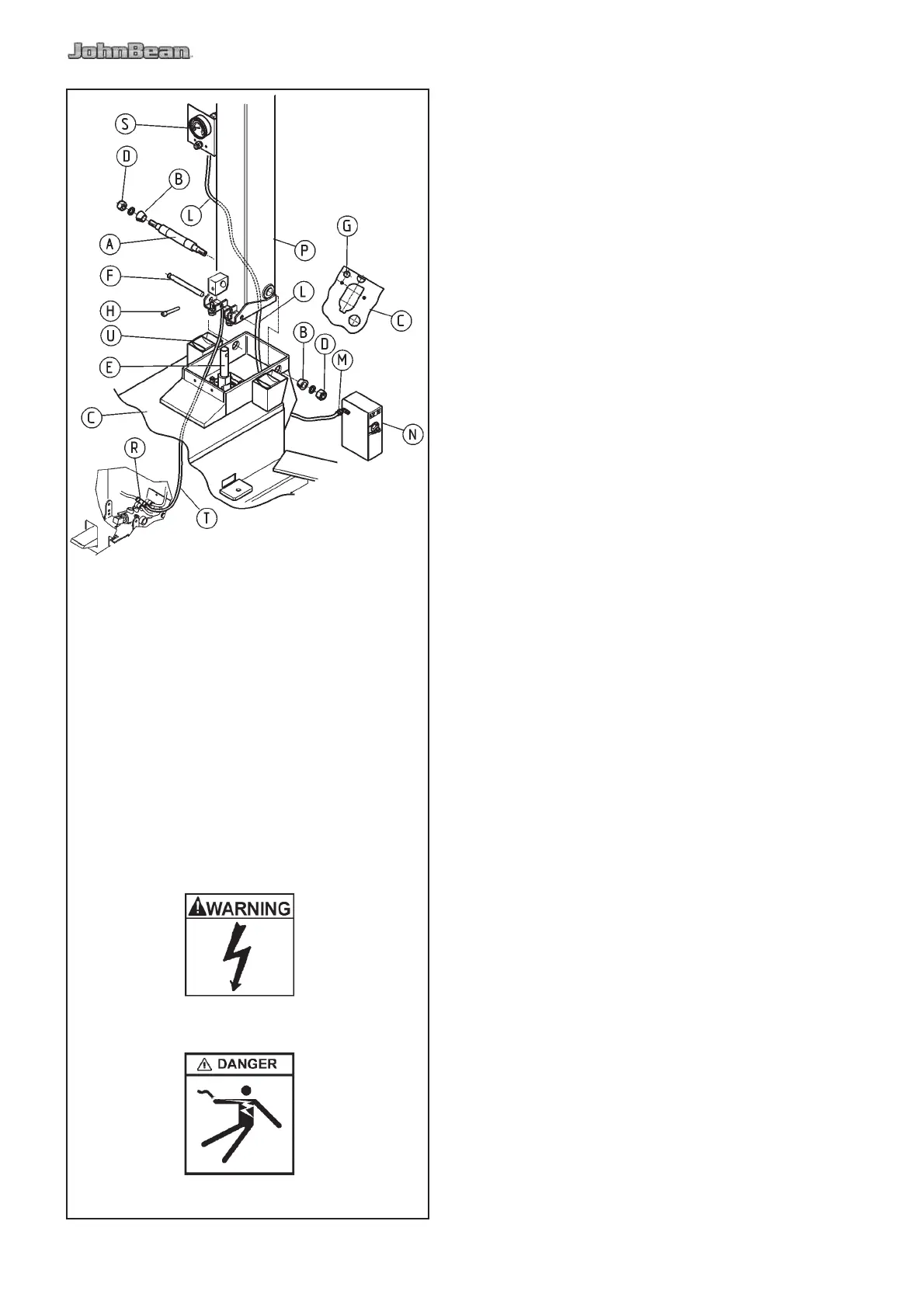

D.

Tilt the column backwards. Pull the rod “E” of the tilting

cylinder and connect it to the column with the pin “F”.

Apply N°243 Loctite to the grub screw “H” and tighten

with a tightening torque of 11 Nm.

E.

Fix the manometer ‘S’ with the available screws, as

shown in Fig. 2.0-1.

F.

Connect the air hose ‘L’ (Fig. 2.0-1) coming from the

tool box ‘S’ (Fig. 2.0-1) to the ! tting ‘M’ of the device

‘N’ (Fig. 2.0-1).

G.

Mount the carter ‘U’ (Fig. 2.0-1), by tightening the

screws ‘Z’.

Mount the lube pail with the available screw.

H.

Secure the tire changer to the " oor as described in

chapter 2.2.

2.1 ELECTRICAL INSTALLATION

WARNING!

THE ELECTRICAL INSTALLATION MUST BE MADE

BY A LICENSED ELECTRICIAN.

Check that the electrical speci! cations of the power

source are the same of the machine. The machine

uses 115 V AC 60 Hz, single phase 20 amp source.

Electric speci! cations are clearly marked on a label at

the end of the electric cord.

If the plug is provided disregard this paragraph.

Connect the electric cord of the machine with an

approved plug. The ground cable (green and yellow)

must be properly connected.

DANGER

FAILURE TO PROVIDE PROPER ELECTRICAL

SUPPLY AND GROUNDING WILL CREATE A

SHOCK HAZARD TO THE OPERATOR.

Loading...

Loading...