40

5.2-1

5.1-1

5.1-2

5.1-3

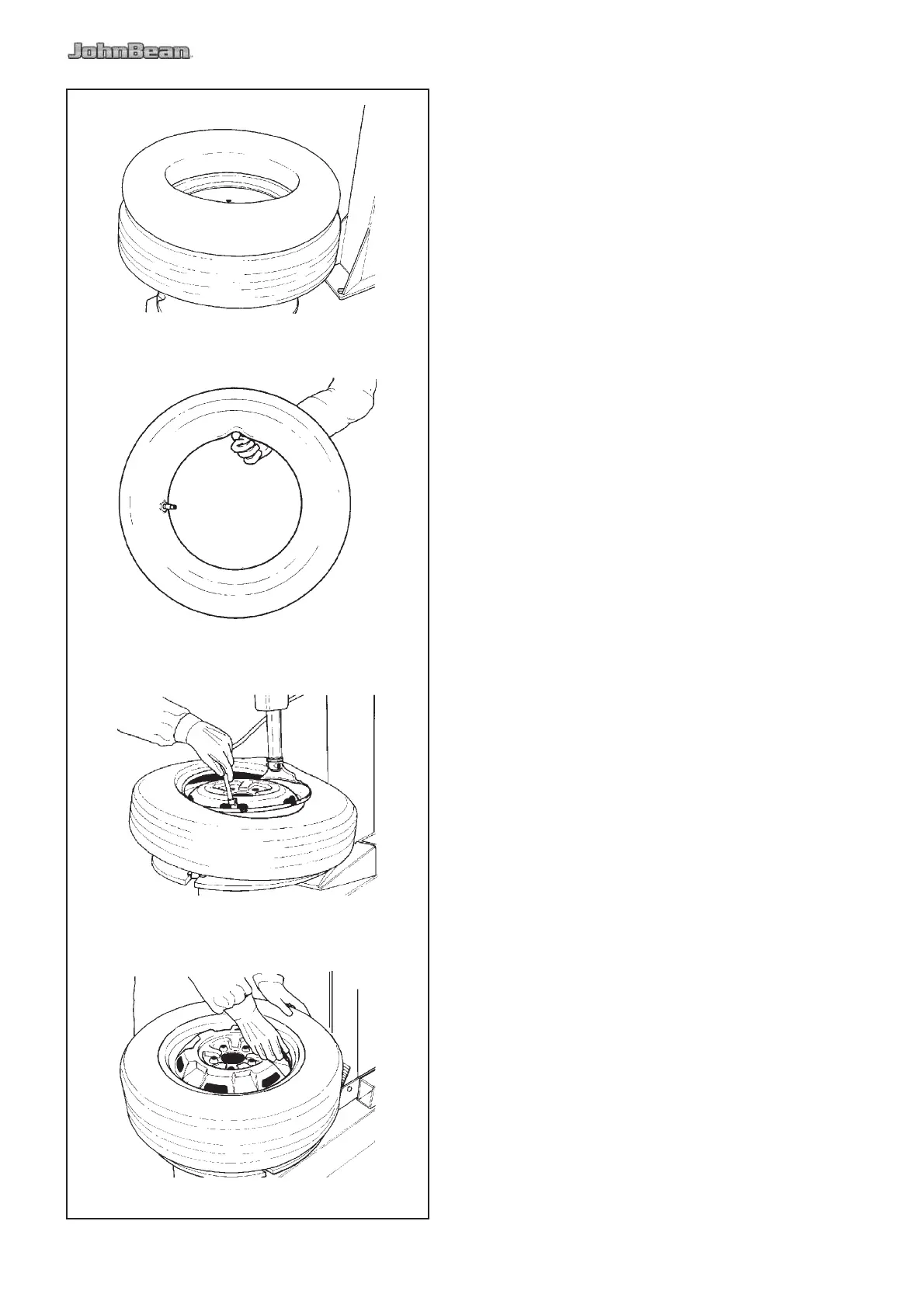

5.1 Mounting tube-type tires

A. Proceed as described in section 4.2.A.

Do NOT lubricate the tube. Talc can be used to assist

with the tube positioning.

B. Mount the valve core and place the tube onto the tire

to con! rm that the tube is of the correct size (Fig. 5.1-1).

C. In" ate the tube slightly: if held with the index ! nger

it should bend a little (Fig. 5.1-2).

D. Mount the ! rst bead as described in section 4.2.B.

Put the tube inside the tire and secure the valve with

the chuck of the in" ating hose (Fig. 5.1-3).

Mount the top bead following the directions above.

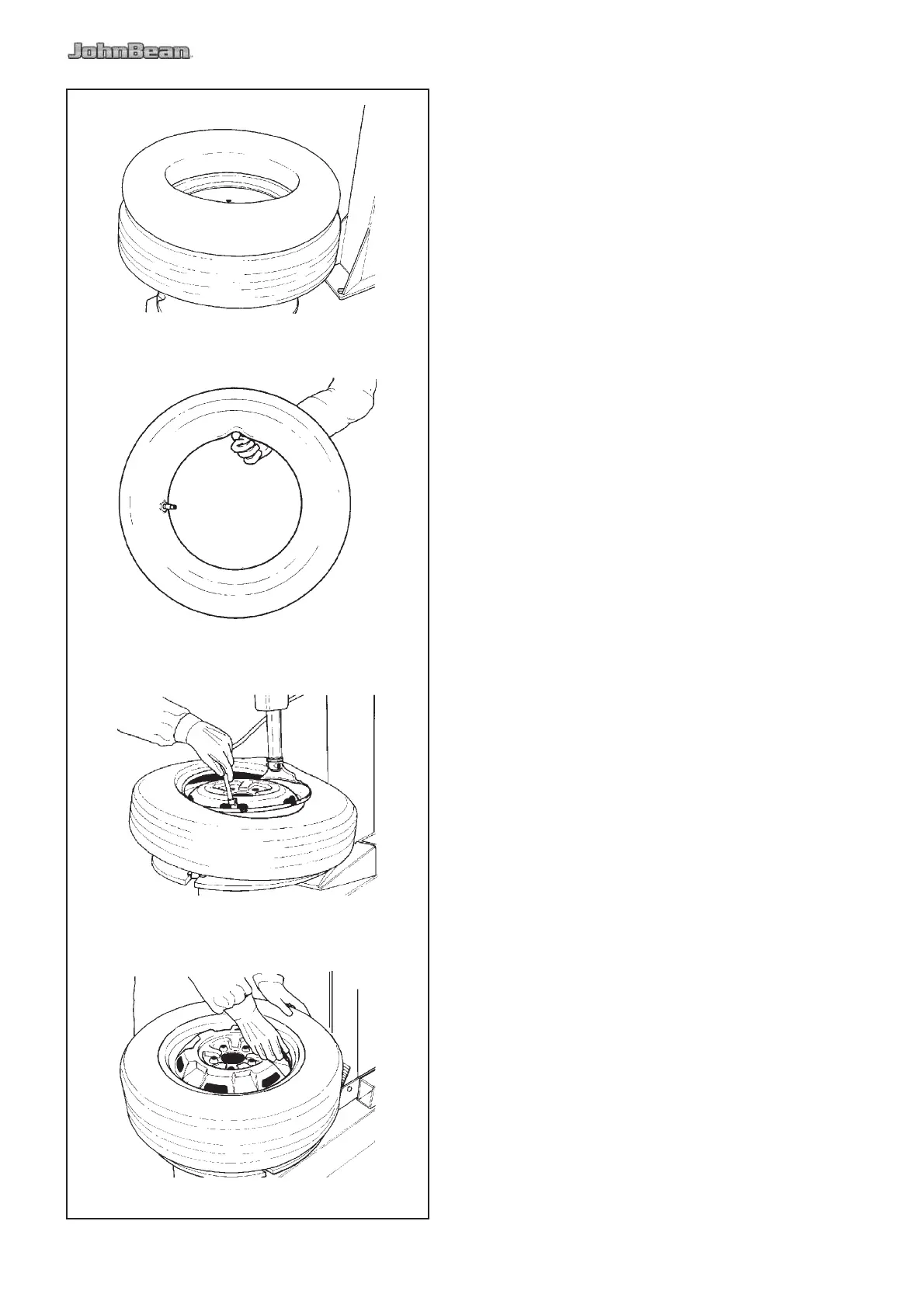

5.2 In! ating tube-type tires

To in" ate the tires unlock the rim and start in" ating

while pressing the valve towards the inside. This is

necessary to avoid air pockets forming between tube

and tire (Fig. 5.2-1).

Ensure that the tire is correctly centered on the rim and

complete in" ation as described in section 4.3.

5.0 Demounting tube-type tires

A. For breaking the bead operate as described for the

tubeless tires in § 4.1.A to 4.1.F.

In this case, the valve is part of the tube

WARNING: BE CAREFUL NOT TO DAMAGE

THE TUBE DURING THE BEAD-BREAKING

OPERATION. THE VALVE SHOULD BE OPPOSITE

TO THE BLADE OF THE BEAD BREAKER.

NOTE: In order to avoid damage to their surface

! nish, alloy rims should be clamped from

the outside only.

Special plastic caps are available as optional extras

for the clamping jaws so that alloy rims

can be clamped carefully.

B. To demount the ! rst bead, place the valve at 3

o’clock position.

WARNING

DO NOT CATCH THE TUBE WITH THE BEAD

LIFTING TOOL, WHEN LIFTING THE BEAD ON

THE MOUNTING FINGER

After demounting the ! rst bead remove the tube before

demounting the second bead, as described in section 4.1.

Loading...

Loading...