070.550-IOM (JUN 2016)

Page 16

NGC GAS ROTARY SCREW COMPRESSOR

OPERATION

High stage compressor loading: The compressor loads

when MSV solenoid YY2 is energized and oil ows from the

unload side of the cylinder out port SC1, through valve

ports A and T to compressor suction. Simultaneously,

discharge pressure loads the slide valve.

High stage compressor unloading: The compressor unloads

when MSV solenoid YY1 is energized and oil ows from the

oil manifold through valve ports P and A to cylinder port

SC1 and enters the unload side of the cylinder.

Simultaneously, gas on the load side of the cylinder is

vented through port SC2 and valve BP to compressor

suction.

NOTICE

To control the rate of loading and unloading, throttle

the needle valve at SC1 port.

DOUBLE-ACTING MODE - Booster (low differential)

Open valve at SC1

Open valve at SC2

Close valve at BP (bypass)

Booster Compressor Loading: The compressor loads when

MSV solenoid YY2 is energized and oil ows from the oil

manifold through valve ports P and B to cylinder port SC2

and enters the load side of the cylinder. Simultaneously, oil

contained in the unload side of the cylinder ows out cylinder

port SC1 through valve ports A and T to compressor suction.

Booster Compressor Unloading: The compressor unloads

when MSV solenoid YY1 is energized and oil ows from the

oil manifold through valve ports P and A to cylinder port

SC1 and enters the unload side of the cylinder.

Simultaneously, oil contained in the load side of the cylinder

ows out of compressor port SC2 through valve ports B and

T to compressor suction.

NOTICE

To control the rate of loading and unloading, throttle

valves SC1 and SC2.

NOTICE

To slow all valve movements - loading, unloading, and

VI change - throttle valve 2.

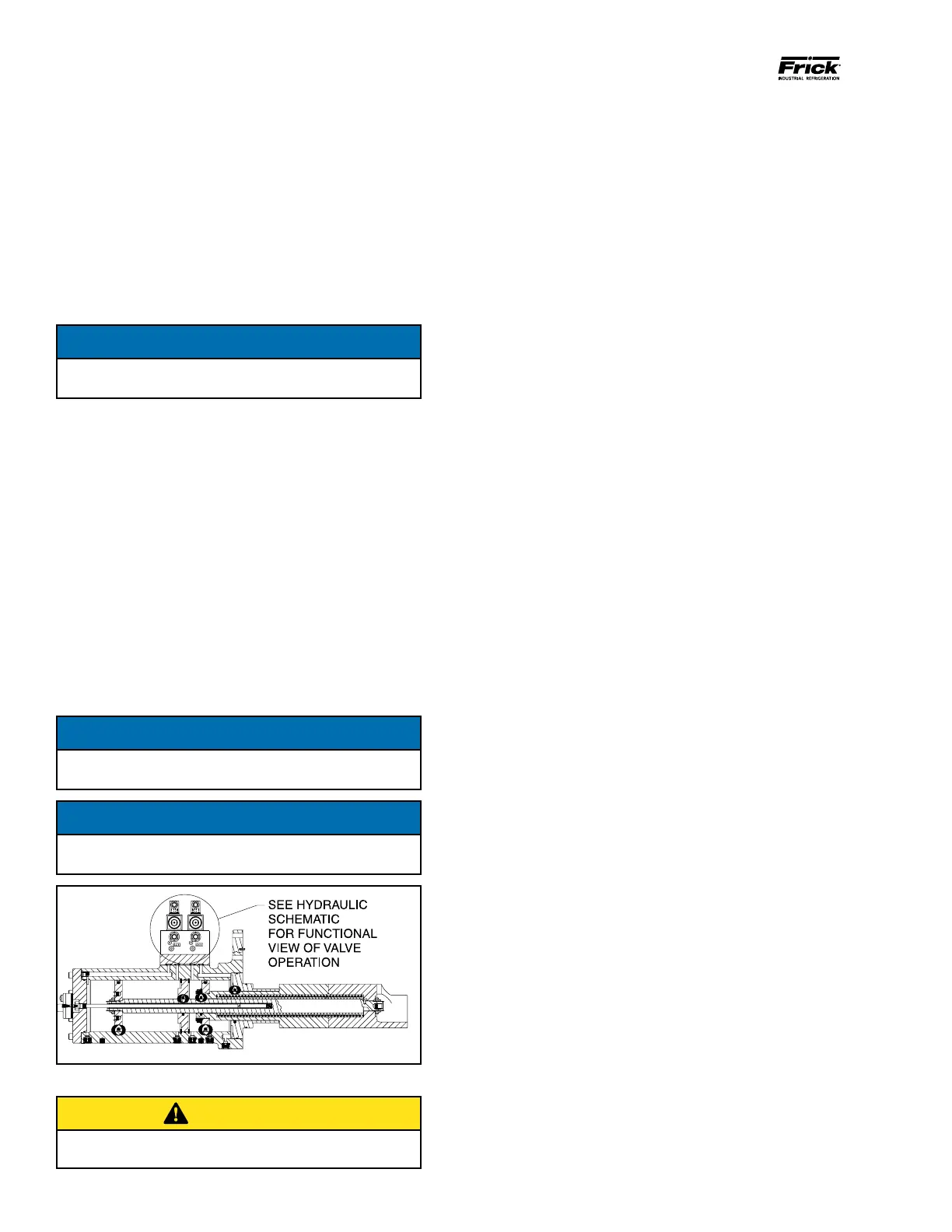

Figure 13 - Solenoid Valve Block

CAUTION

NEVER open valve BP and valve SC2 at the same time

during compressor operation.

VOLUMIZER VOLUME RATIO CONTROL

Open valve at SC3

Open valve at SC4

Compressor VI increase: The volume ratio Vi is increased

when MSS solenoid valve YY3 is energized and oil ows

from the oil manifold through valve ports P and A to

compressor port SC3, enters the increase side of the

cylinder and overcomes the decrease spring tension.

Simultaneously, oil ows from SC4 port through valve ports

B and T to compressor suction.

Compressor VI decrease: The volume ration Vi is decreased

when MSS solenoid valve YY4 is energized and oil ows

from the oil manifold through valve ports P and B to

compressor port SC4, enters the decrease side of the

cylinder. Simultaneously, oil ows form SC3 port through

valve ports A and T to compressor suction.

TO CONTROL THE RATE OF VI CHANGE, THROTTLE THE

NEEDLE VALVE AT SC3 PORT.

LOW AMBIENT OPERATION

It is recommended that package oil separators be insulated

as a minimum requirement to preserve the heat generated

by the oil heaters, to prevent condensation and secure

lubrication at start-up.

INITIAL STARTUP

Prior to the start-up, the packager’s prestart check must

be accomplished.

INITIAL STARTUP PROCEDURE

Having performed the packager’s prestart check, the

compressor unit is ready for start-up. It is important that an

adequate gas load be available to load test the unit at

normal operating conditions. The following points should

be kept in mind during initial start-up.

1. For proper and safe operation, the compressor must be

run at the proper speed and discharge pressure. Exceeding

design conditions creates a potential hazard.

2. After 1 to 3 hours of operation adjust oil cooling system.

3. Pull and clean suction strainer after 24 hours of operation.

If it is excessively dirty, repeat every 24 hours until system

is clean. Otherwise, follow the normal maintenance

schedule.

4. Perform vibration analysis if equipment is available.

NORMAL STARTUP PROCEDURE

1. Conrm system conditions permit starting the

compressor.

2. Start.

3. Observe the compressor unit for mechanical tightness of

the external piping, bolts and valves. Ensure that the

machine has no oil and vapor leaks. If any of these occur,

shut down the compressor and correct the problem as

necessary using good safety precautions.

Loading...

Loading...