070.550-IOM (JUN 2016)

Page 19

NGC GAS ROTARY SCREW COMPRESSOR

INSTALLATION - OPERATION - MAINTENANCE

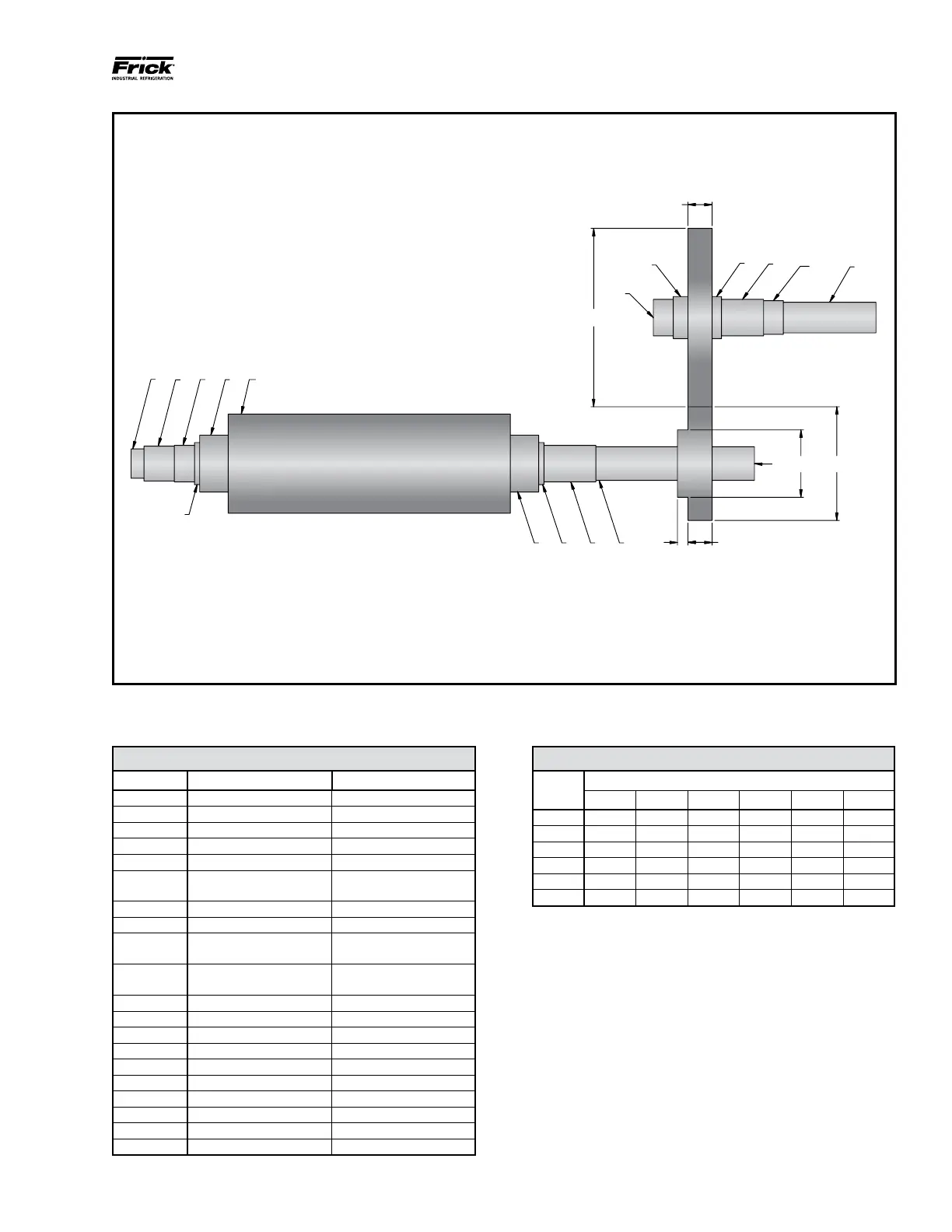

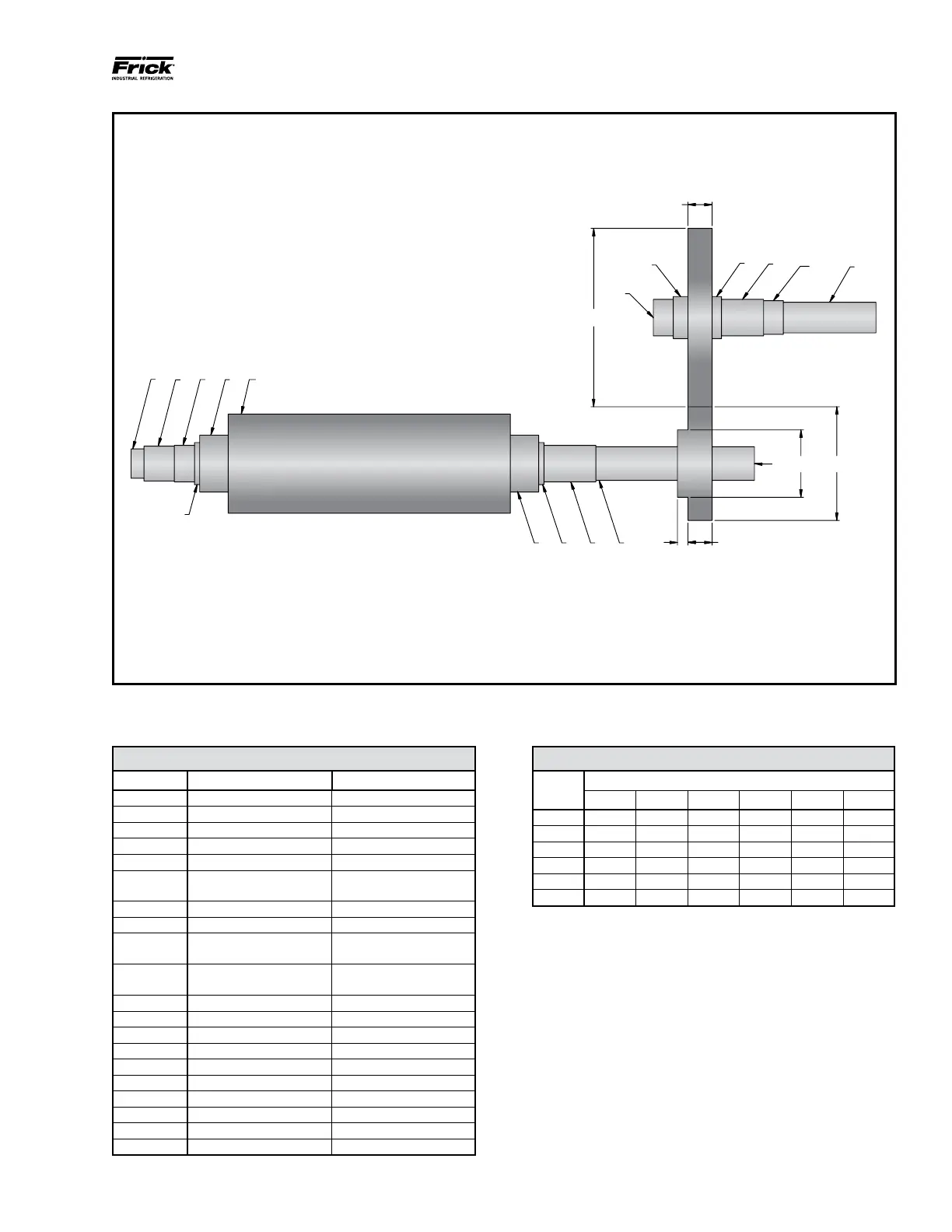

Figure 14. Torsional Analysis, NGC and NGCH 400/450 Driveline and Gear Dimensions.

NGC/NGCH Driveline Dimensions (Less Gears)

SEGMENT DIAMETER* LENGTH*

1 3.5 1.54

2 4.13 3.61

3 4.33 2.39

4 5 .62

5 6.75 3.38

6 11.79

15.37 (NGC/H 400)

33.53 (NGC/H 450)

7 6.75 3.38

8 5 .62

9 4.33

4.96 (NGC 400/450)

6.16 (NGCH 400/450)

10 4

10.98 (NGC 400/450)

9.79 (NGCH 400/450)

11 See Gear Dimensions See Gear Dimensions

12 See Gear Dimensions See Gear Dimensions

13 4.33 2.36

14 5 5

15 See Gear Dimensions See Gear Dimensions

16 5 1.12

17 4.33 5

18 4 2.35

19 3.75 11

20 4 4.93

*Dimensions in inches

NGC/NGCH Gear Dimensions

GEAR

SET

SEGMENT*

11 11A 12 12A 15 15A

A 8.13 1.25 16.13 3 21.1 2.75

B 8.13 1.25 14.6 3 22.63 2.75

C 8.13 1.25 12.76 3 24.48 2.75

D 8.13 1.25 11.43 3 25.8 2.75

E 8.13 1.25 10.48 3 26.75 2.75

F 8.13 1.25 9.66 3 27.57 2.75

*Dimensions in inches

NOTE: 1. All segments are labeled on the driveline.

Refer to corresponding tables for dimensions.

2. Male rotor body diameter, Segment 6, is an equivalent

diameter which is dependent on rotor prole geometry.

3. Diagram is subject to change. This drawing is current

as of 04/16/2014 (Rev. 09). Article 3800 in the CES

manual displays current revision level.

4. This is a representation of an NGC and NGCH 400/450

driveline and intended to be used for torsional

vibration analysis.

1

32

4

5

6

8 9 10

11

13

14

16

17

18

19

Male Rotor

Jackshaft

20

12

11A 12A

15

15A

7

TORSIONAL ANALYSIS

Loading...

Loading...