070.550-IOM (JUN 2016)

Page 12

NGC GAS ROTARY SCREW COMPRESSOR

INSTALLATION

HOLDING CHARGE AND STORAGE

Every NGC compressor is pressure and leak tested at the

factory and then thoroughly evacuated and charged with dry

nitrogen to ensure its integrity during shipping and short

term storage prior to installation.

All compressors must be kept in a clean, dry location to

prevent corrosion damage. Compressors that will be stored

for more than two months must have their nitrogen charge

checked periodically (see pages in GENERAL INFORMATION

for complete instructions).

WARNING

Holding-charge shipping gauges (if mounted) are rated

for 30 psig and are for checking the shipping charge

only. They must be removed before pressure testing

and operating the system. Failure to remove these

gauges may result in catastrophic failure of the gauge

resulting in serious injury or death.

CAUTION

Cylinder assembly under high spring load. Consult

manual before disassembly. Improper disassembly may

cause injury due to spring tension release.

RIGGING AND HANDLING

The compressor can be moved with rigging, using a crane

or forklift, by hooking into the two lifting rings at each end

of the main housings. The compressor lifting rings shall only

be used to lift the compressor itself. See Figure 7.

Figure 7 - Lifting Rings

DEHYDRATION / EVACUATION TEST

Evacuate the system to 1000 microns. Valve off the vacuum

pump and hold vacuum for one hour.

Pass – Vacuum cannot rise more than 500 microns during

one hour hold period.

Fail – Vacuum rise is more than 500 microns during one

hour hold period. Identify and repair any system leaks.

Repeat vacuum test until requirements are met.

FOUNDATION

Each NGC Rotary Screw Compressor is shipped mounted on

a wooden skid, which must be removed prior to unit

installation.

CAUTION

Allow proper spacing for servicing (see Dimensional

Outline Drawing).

The rst requirement of the compressor foundation is that

it must be able to support the weight.

NGC 100 2900 lb NGC 300 6,700 lb

NGC 150 3150 lb NGC 400 10,000 lb

NGC 200 4400 lb NGC 450 13,200 lb

NGC 250 4800 lb

Screw compressors are capable of converting large

quantities of shaft power into gas compression in a relatively

small space. The compression process creates relatively

high frequency vibrations that require sufcient mass in the

base to effectively dampen them.

The best insurance for a trouble-free installation is to rmly

anchor the compressor to a suitable foundation using

proper bolting and by preventing piping stress from being

imposed on the compressor. Once the compressor is rigged

into place, its feet must be shimmed to level it. There must

be absolutely no stresses introduced into the compressor

body due to bolting of the feet and anges.

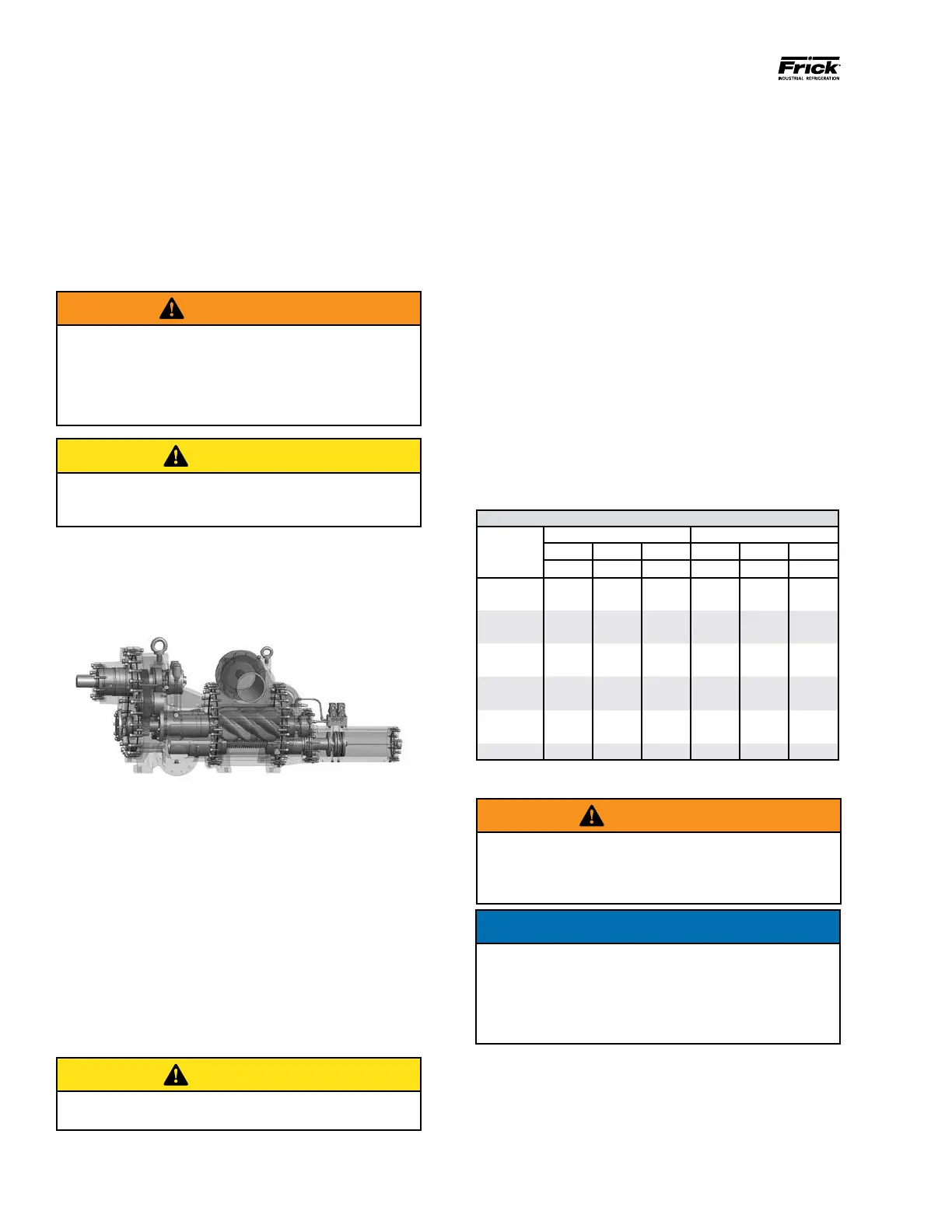

In any screw compressor installation, suction and discharge

lines should be supported in pipe hangers (preferably within

2 ft. of vertical pipe run) so that the lines won’t move if

disconnected from the compressor. See table for Allowable

Flange Loads.

ALLOWABLE FLANGE LOADS

NOZ. MOMENTS (ft-lbf) LOAD (lbf)

SIZE AXIAL VERT. LAT. AXIAL VERT. LAT.

NPS M

R

M

C

M

L

P V

C

V

L

1 25 25 25 50 50 50

1.25 25 25 25 50 50 50

1.5 50 40 40 100 75 75

2 100 70 70 150 125 125

3 250 175 175 225 250 250

4 400 200 200 300 400 400

5 425 400 400 400 450 450

6 1,000 750 750 650 650 650

8 1,500 1,000 1,000 1,500 900 900

10 1,500 1,200 1,200 1,500 1,200 1,200

14 2,000 1,800 1,800 1,700 2,000 2,000

COMPRESSOR OIL

WARNING

DO NOT MIX OILS of different brands, manufacturers,

or types. Mixing of oils can cause excessive oil foam-

ing, nuisance oil level cutouts, oil pressure loss, gas or

oil leakage and catastrophic compressor failure.

NOTICE

The Frick oil recommended for the application is the

best suited lubricant for the conditions specied at the

time of purchase. If there is any doubt due to the gas

composition, operating pressures, or temperatures,

refer to Johnson Controls-Frick publications 160-810

NGO and E160-802 SPC for guidance.

OIL FILTER(S)

Use of lter elements other than Johnson Controls - Frick

must be approved in writing by Johnson Controls - Frick

engineering or a warranty claim may be denied. Typical oil

lter specication β

5

= 75 according to ISO 4572 is required

to obtain the recommended oil cleanliness class 16/14/11

according to ISO 4406.

Loading...

Loading...