10

P00792Q-rev.2

4. Installation Location

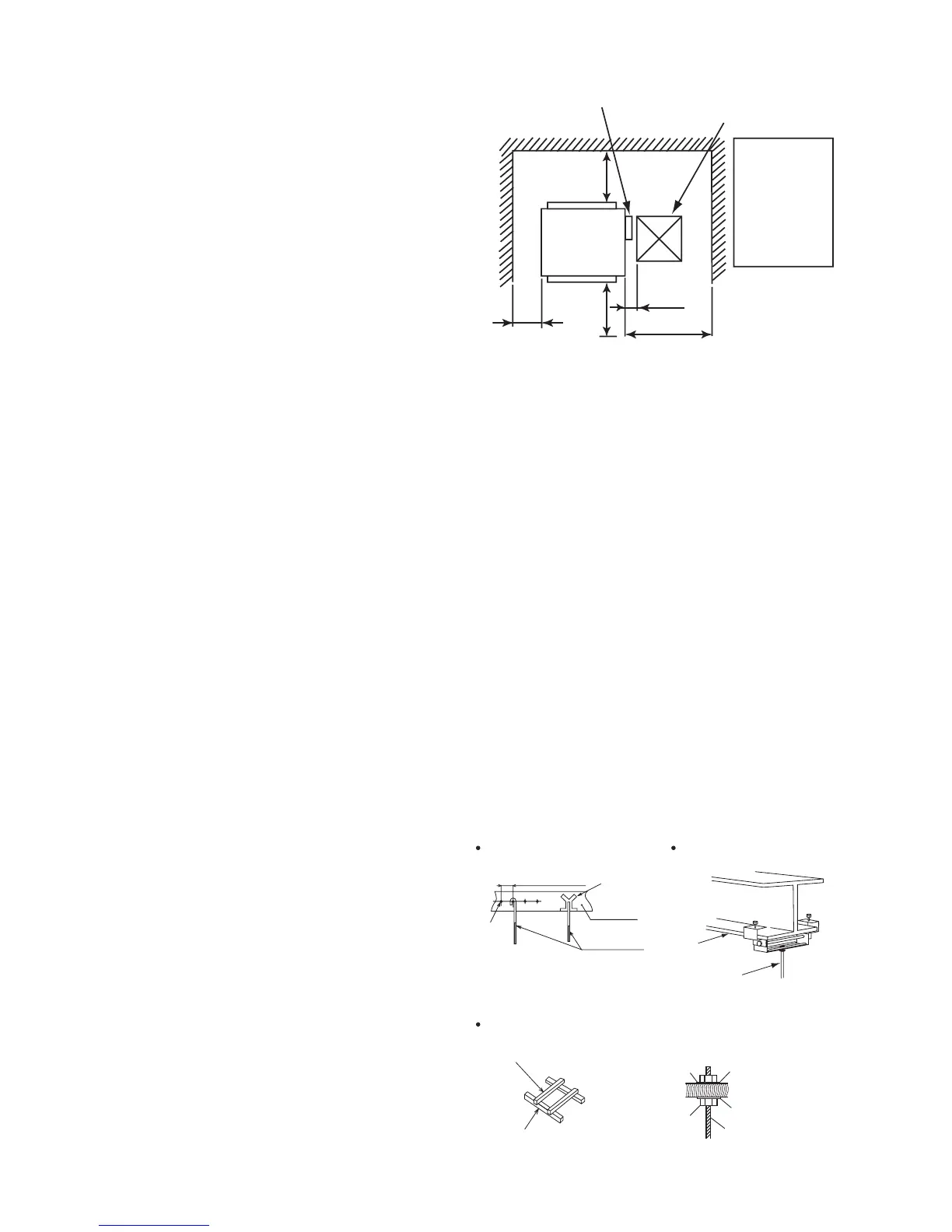

Figure. 4.1 Operation and Installation Space

(1) Install the indoor unit, allowing for proper

clearance for operation and maintenance

access, as shown in Figure. 4.1.

Rear Side

Min. 39-3/8

(1000)

Service Access Door

(Min

□

17-11/16 (450))

In case that the

ceiling board can

not be detected

for servicing,

prepare a service

access door

below the indoor

unit for removing

the indoor unit.

Min. 39-3/8

(1000)

Min. 23-5/8

(600)

(2) Consider the air distribution from the indoor unit to the space of the room, and select a suitable location

so that uniform air temperature in the room can be obtained.

(3) Do not leave combustible materials inside the service space of the indoor unit.

(4) Avoid obstacles which may hamper the air intake or the air discharge ow.

(5) Do not install the indoor unit in a machine shop or kitchen where vapor from oil or its mist ows to the

indoor unit.

The oil will deposit on the heat exchanger, thereby reducing the indoor unit performance, and may

deform and in the worst case, break the plastic parts of the indoor unit.

(6) Pay attention to the following points when the indoor unit is installed in a hospital or other facilities

where there are electronic waves from medical equipment.

(a) Do not install the indoor unit where the electromagnetic wave is directly radiated to the electrical

box, communication cable or wired controller.

(b) Install the indoor unit and components as far away as practical or at least 9.8ft (3m) from any

electromagnetic wave radiator.

(c) Prepare a steel box and install the wired controller in it. Prepare a steel conduit tube and wire the

controller cable in it. Then, connect the ground wiring with the box and the tube.

(d) Install a noise lter when the power supply emits harmful noises.

(7) To avoid any corrosive action to the heat exchangers, do not install the indoor unit in an acid or alkaline

environment.

5. Installation Work

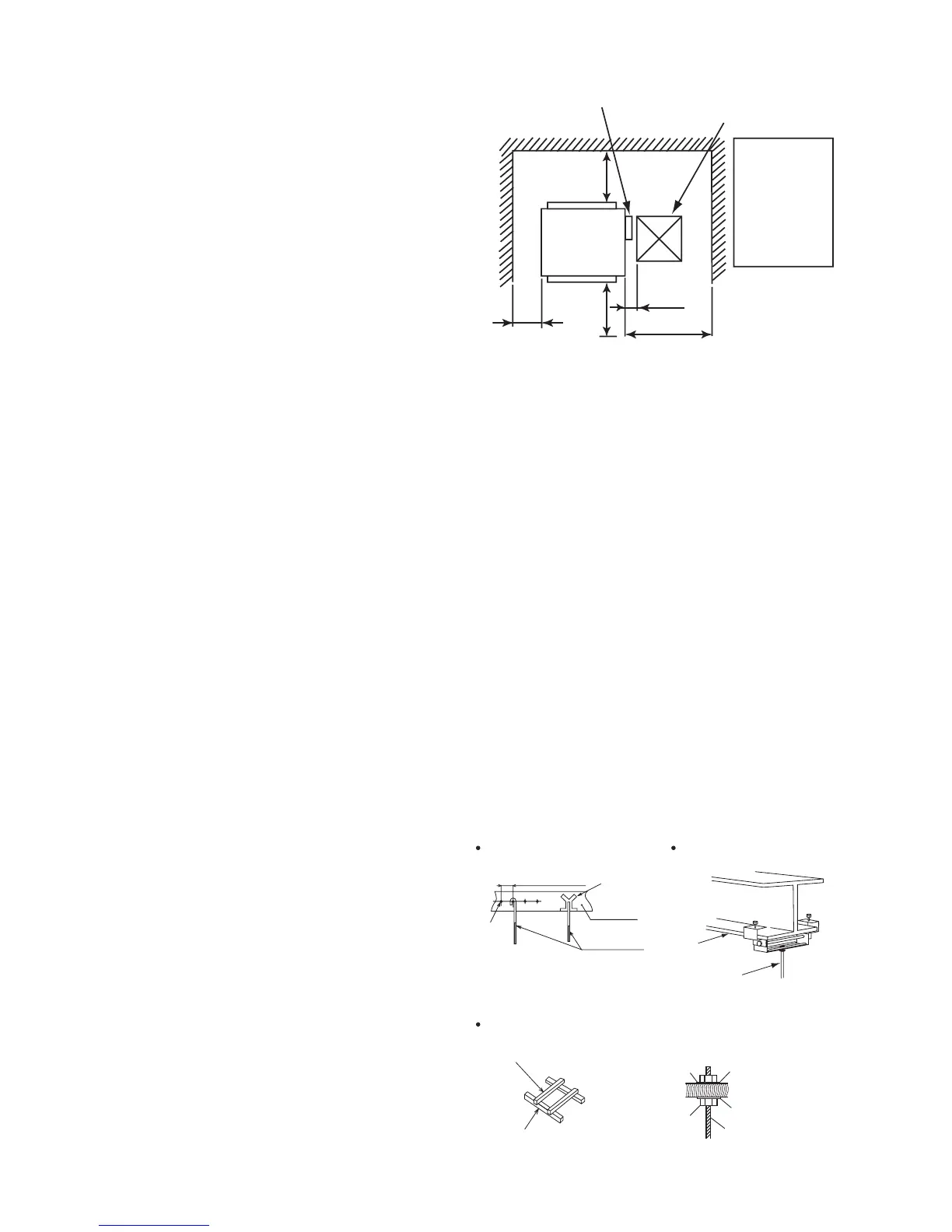

5.1 Suspension Bolts

(1) Determine the nal location and installation

orientation of the indoor unit with respect

to the space allowed for piping, wiring, and

maintenance access.

(2) Mount suspension bolts, as shown in Figure

5.1.

5-7/8 to 6-5/16

Insert

(221 to 331 lbs)

I Beam

Loading...

Loading...