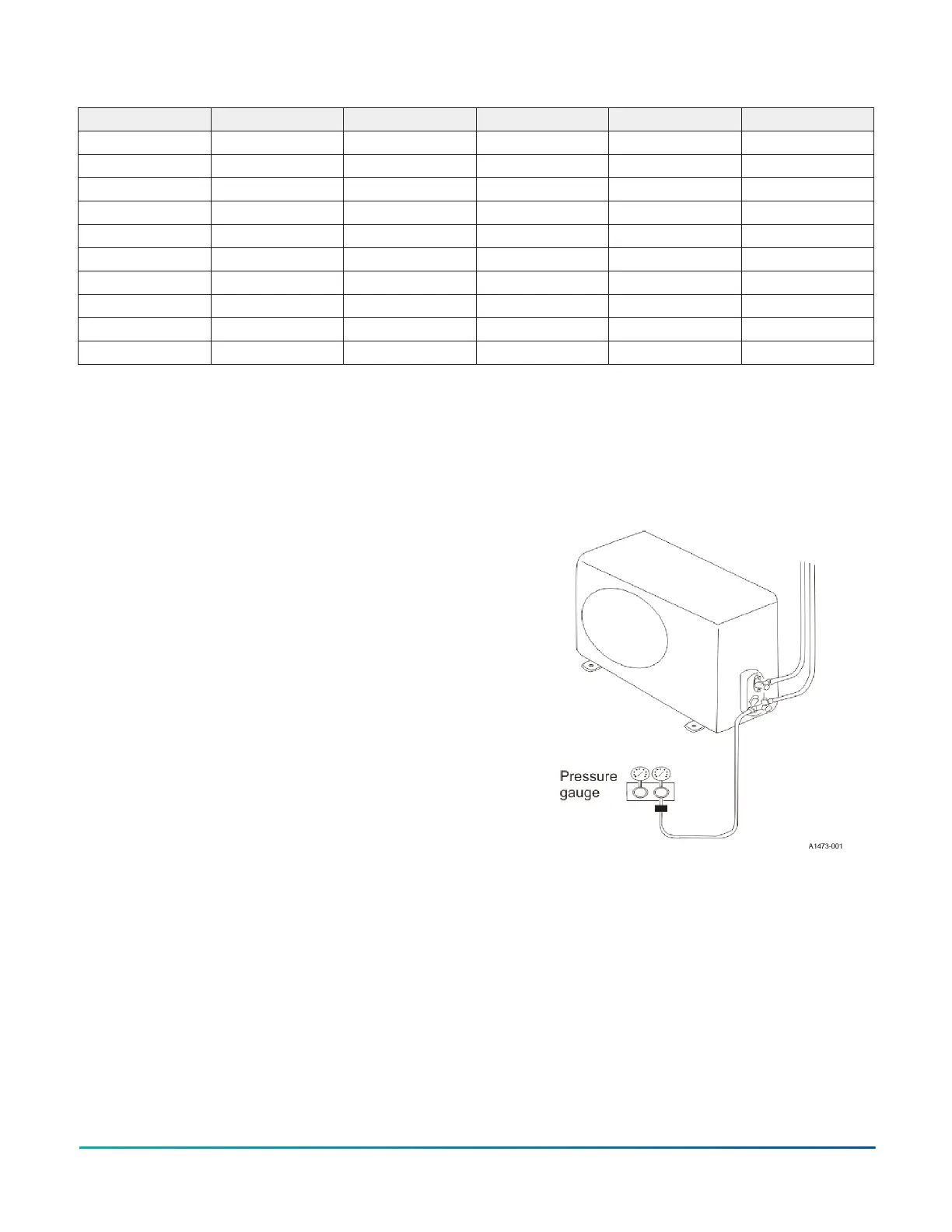

Table 9: Suction, ambient, coil, and discharge sensors

T [ ℃ ] Rmin [ KΩ ] Rnom [ KΩ ] Rmax [ KΩ ] Dev(MIN)% Dev(MAX)%

-30 60.78 64.77 68.99 -6.16 6.12

-15 29.07 29.97 30.89 -3.00 2.98

0 14.70 15.00 15.29 -2.00 1.90

15 7.804 8.021 8.240 -2.71 2.66

30 4.355 4.550 4.753 -4.29 4.27

45 2.558 2.701 2.850 -5.29 5.23

60 1.551 1.654 1.762 -6.23 6.13

75 0.9676 1.041 1.120 -7.05 7.05

90 0.6188 0.6718 0.7291 -7.89 7.86

105 0.4056 0.4440 0.4859 -8.65 8.62

Troubleshooting

Variable capacity systems can be difficult to troubleshoot

considering integrated fault isolation and protection

algorithms. When the HP system is not operating within

acceptable parameters or there is a need to verify system

or component operation, it may be necessary to perform

specific system checks. Follow the troubleshooting steps,

component checks, and fault code/resolution tables in

this section to isolate potential root causes.

Checking components

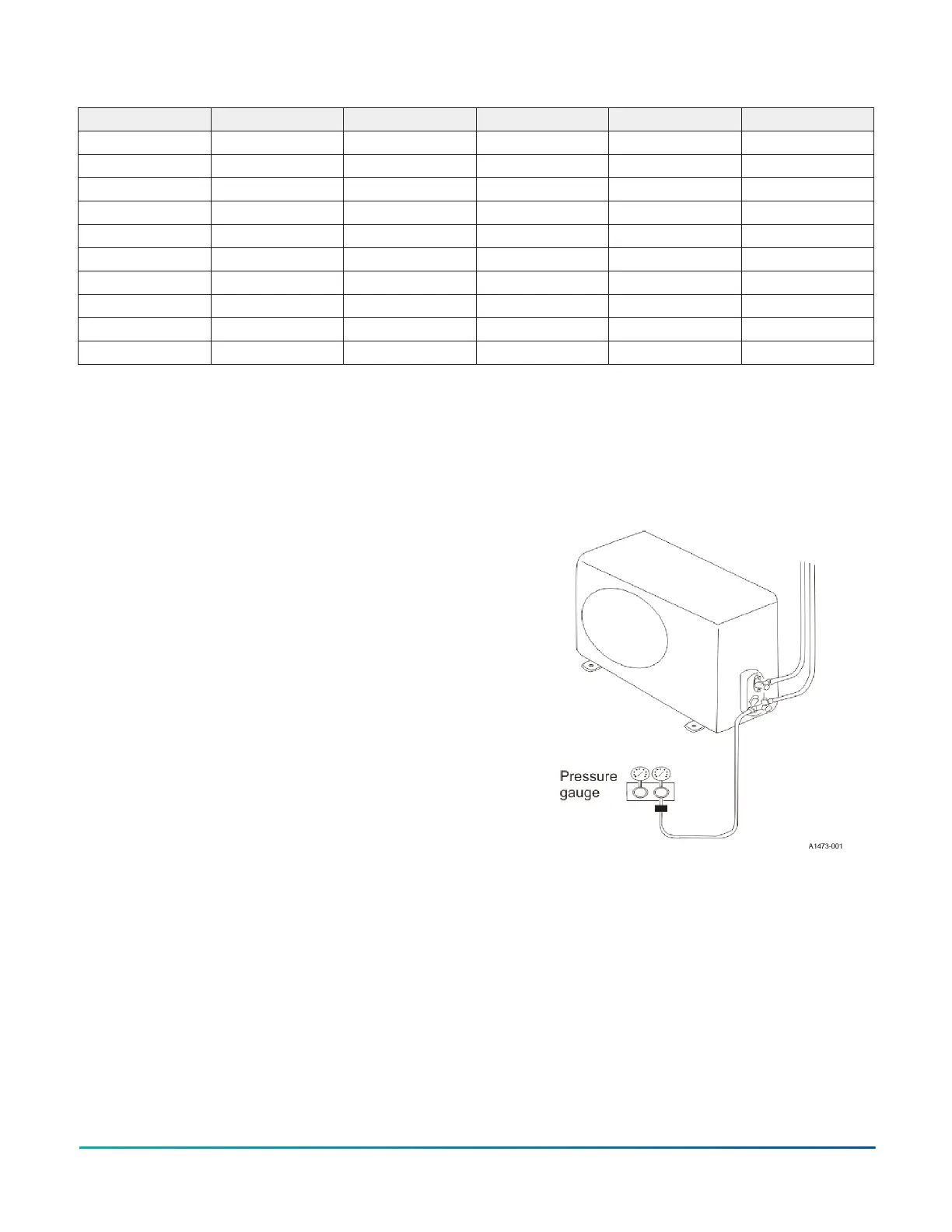

Check the refrigerant system.

Test system flow

Conditions:

• The compressor is running.

• The outdoor section is installed in a well-ventilated

area.

Tool

Pressure gauge:

• See: Tube defrost

• Feel: The difference between the tube's temperature

• Test: Test pressure

Figure 37: Refrigerant system

Installation Manual: HMH7 Series - 17 SEER Horizontal Discharge Modulating Heat Pump32

Johnson Controls Ducted Systems

Loading...

Loading...