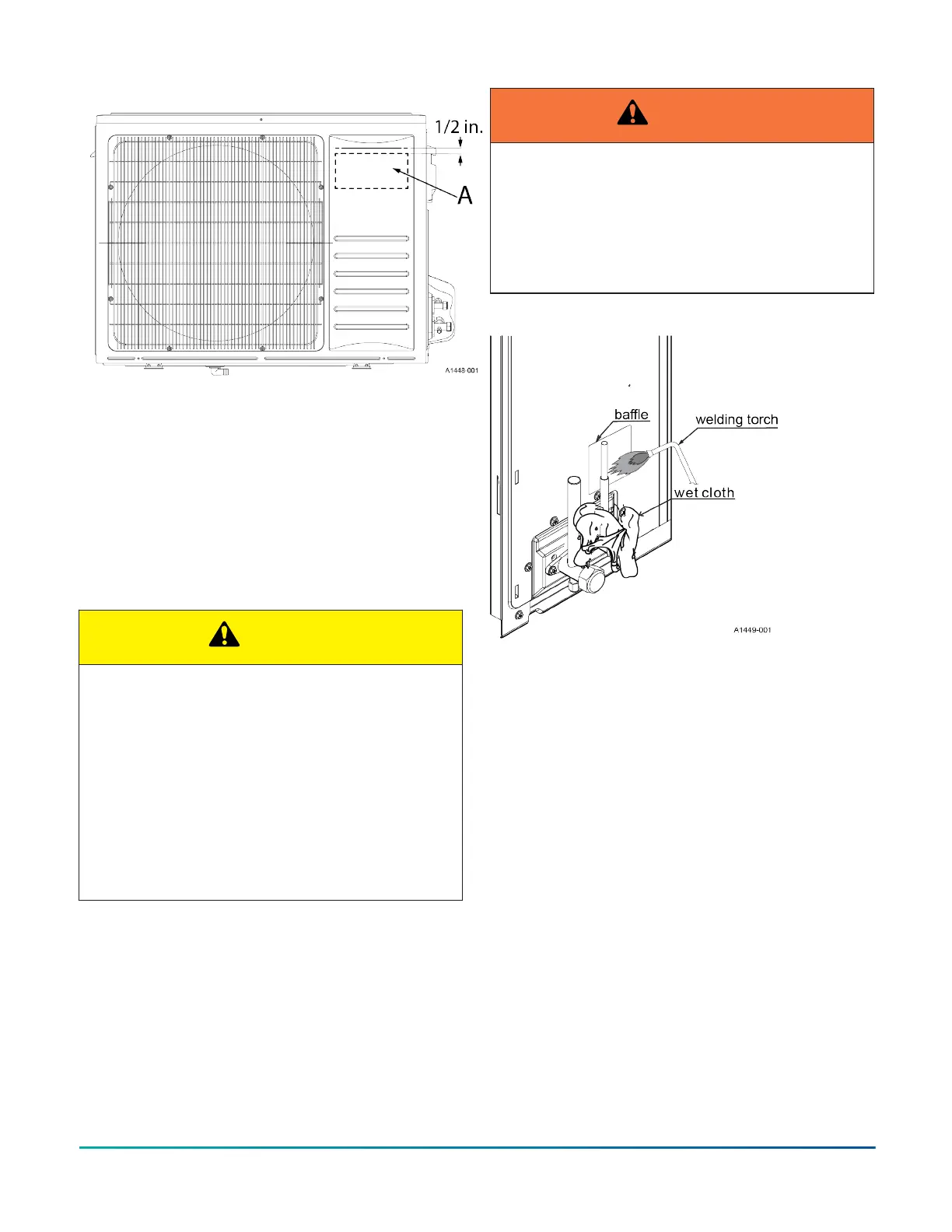

Figure 11: Brand label location

Precautions for brazing of lines

All outdoor unit and indoor coil connections are copper-

to-copper and must be brazed with a phosphorous-

copper alloy material such as Silfos-5 or equivalent. Do

not use soft solder. The outdoor units have reusable

service valves on both the liquid and vapor connections.

The total system refrigerant charge is retained within

the outdoor unit during shipping and installation. The

reusable service valves are provided to evacuate and

charge per this instruction. Serious service problems can

be avoided by taking adequate precautions to ensure an

internally clean and dry system.

CAUTION

The indoor coil is under inert gas pressure. Relieve

pressure from the coil by depressing the Schrader

core at the end of the suction manifold stub out. Dry

nitrogen must always be supplied through the tubing

while it is being brazed because the temperature

required is high enough to cause oxidation of the

copper, unless an inert atmosphere is provided.

The flow of dry nitrogen must continue until the joint

cools. Always use a pressure regulator and safety

valve to insure that only low pressure dry nitrogen

is introduced into the tubing. Only a small flow is

necessary to displace air and prevent oxidation.

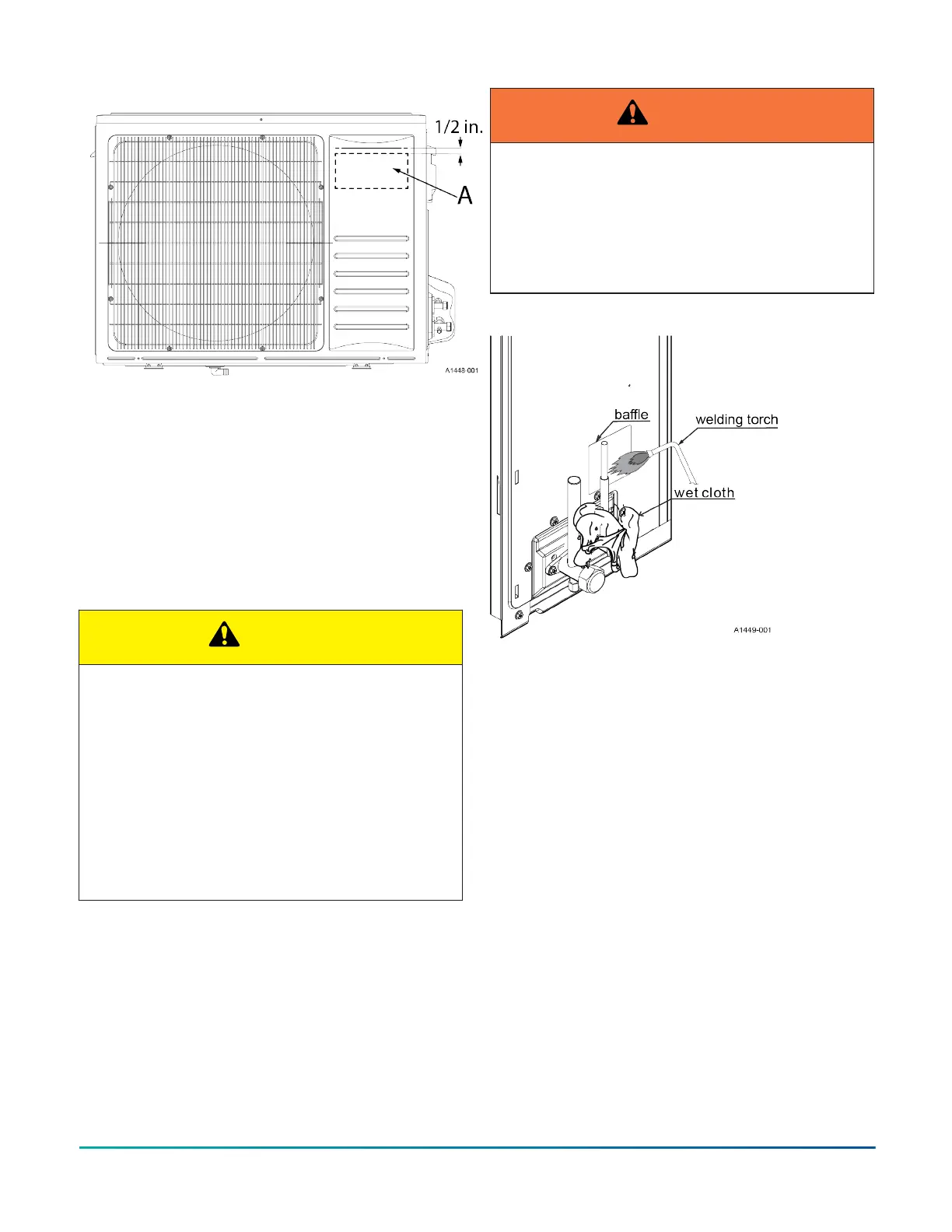

Precautions for brazing of the service valve

• Wrap a wet rag around the service valve to prevent

heat damage, as shown in Figure 12.

• Protect all painted surfaces, insulation, and plastic

base during brazing.

• After brazing, cool the joint with a wet rag.

WARNING

This is not a backseating valve. The service access

port has a valve core. Opening or closing the valve

does not close the service access port. If the valve

stem is backed out past the chamfered retaining

wall, the O-ring can be damaged, causing leakage or

system pressure that could force the valve stem out of

the valve body, possibly causing personal injury.

Figure 12: Brazing the service valve

Connecting the refrigerant lines

About this task:

The valve can be opened by removing the plunger cap

and fully inserting a hex wrench into the stem, then

backing out counter-clockwise until the valve stem just

touches the chamfered retaining wall.

1. Remove the cap and Schrader core from both the

liquid and vapor service valve service ports at the

outdoor unit. Connect low pressure nitrogen to the

liquid line service port.

2. Braze the liquid line to the liquid valve at the

outdoor unit. Ensure to wrap the valve body with a

wet rag. Allow the nitrogen to continue flowing.

3. Carefully remove the plugs from the liquid and

vapor connections at the indoor coil.

4. Braze the liquid line to the indoor coil liquid

connection. Nitrogen should be flowing through

the indoor coil.

5. Slide the grommet away from the vapor connection

at the indoor coil. Braze the vapor line to the

indoor coil vapor connection. After the connection

has cooled, slide the grommet back into original

position.

Installation Manual: HMH7 Series - 17 SEER Horizontal Discharge Modulating Heat Pump 11

Johnson Controls Ducted Systems

Loading...

Loading...