VAV Controller—Variable Air Volume (VAV) Controller 81

The following table indicates symptoms and corrections for typical control

system malfunctions (primarily in pressure independent applications). We

recommend that you use HVAC PRO for Windows Commissioning mode

during all troubleshooting procedures.

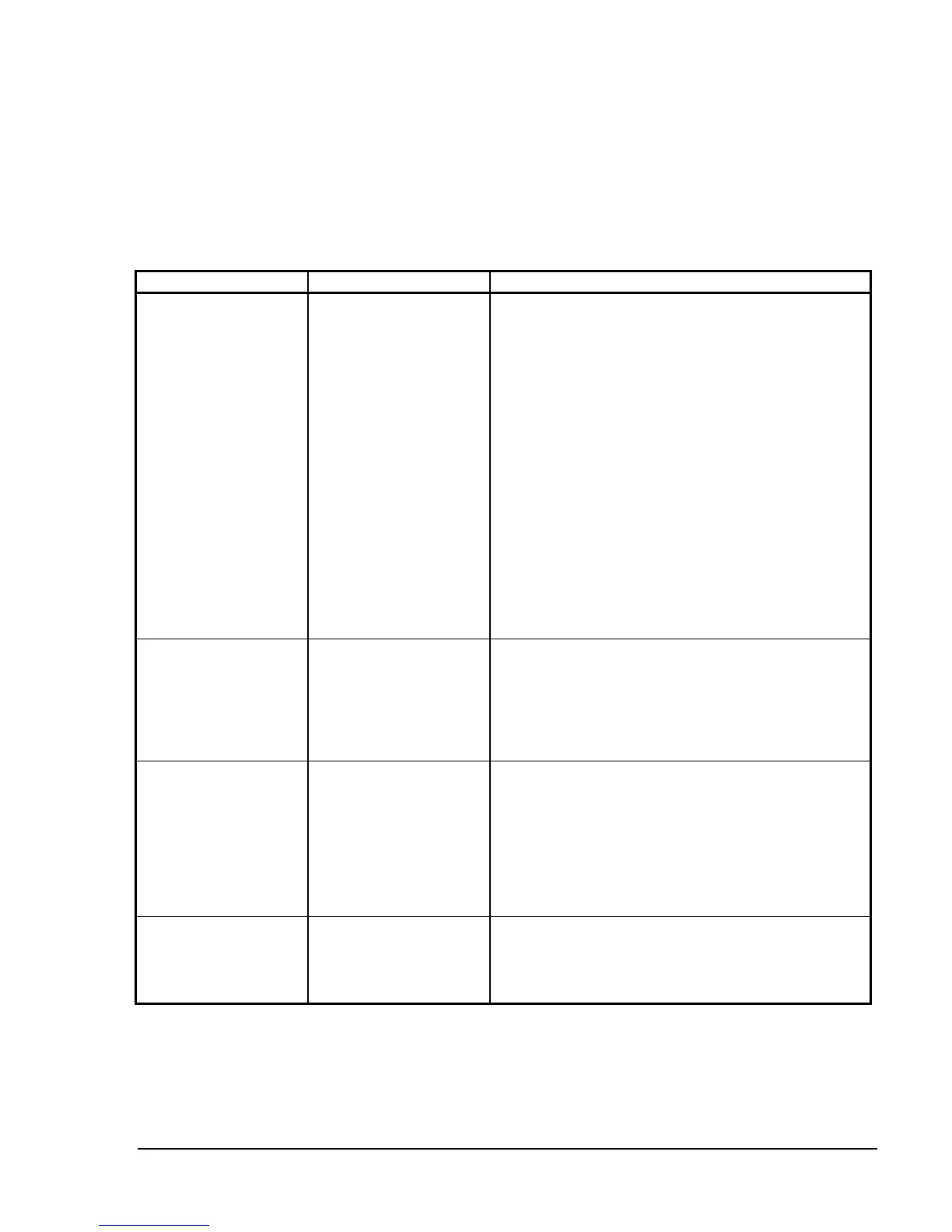

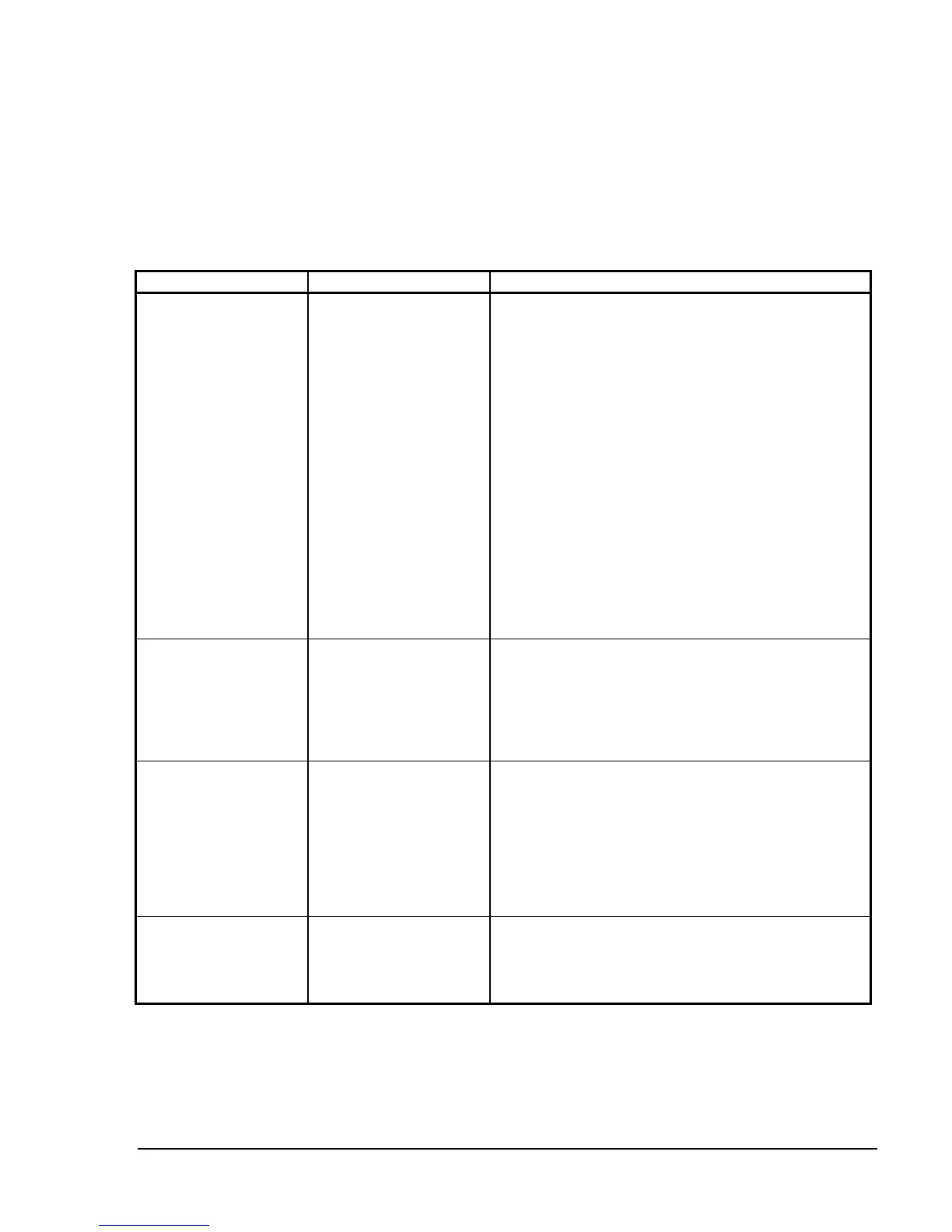

Table 34: VAV Controller Troubleshooting Symptoms and Corrective Actions

Symptom Possible Cause Corrective Action

VAV Controller CFM

readings are not within

10 percent of balancing

contractors readings or

flow readings are not

repeatable.

Velocity Pressure

Transducer out of calibration

by more than 20 percent.

Damper does not seal.

Box Multiplier Constant

and/or Box Area parameters

are not set correctly.

One or both airflow pickup to

DPT tubing connections are

crossed, plugged, or open.

The ductwork configuration

upstream of the airflow

pickup is disturbing the air

flow across the pickup.

Command Auto Zero mode using HVAC PRO for Windows

and read the offset value for the DPT sensor. If the value is

greater than 20 percent of the sensor range, you need to

replace or manually calibrate the transducer.

Override damper closed and verify.

Verify the numbers displayed in the HVAC PRO for Windows

parameters screen against the information on the box, or check

the OEM Reference Manual (FAN 638) for the recommended

numbers per box type.

Check that the high or upstream side of the pickup connects to

the DPT high side, and the downstream side of the pickup

connects to the DPT low side. Check that the tubing is not

plugged and that the test taps are capped.

Turns, transitions, and flex duct should be no closer than

one duct diameter upstream from the airflow pickup. The

takeoff should be at least three duct diameters upstream from

the pickup.

No change in the CFM

value while you are

manually overriding the

damper by changing the

temperature setpoint or

issuing a direct override

to the damper command.

Damper linkage is slipping or

linked incorrectly.

Main system is not supplying

enough air.

Inspect the linkage while the actuator is being commanded to

ensure tight connection.

If the VAV box actuator is linked correctly and you cannot

obtain the maximum CFM setpoint, check the Central System

Static Pressure to ensure enough primary air is being provided

to properly balance the system.

The damper actuator

cycles excessively.

The Supply Deadband

and/or Heating/Cooling Prop

Bands are too narrow.

Electrical noise is present on

zone temperature signal.

Check the Supply Deadband value to ensure that it is greater

than (48*(box inlet area))ft

2

/(4.5*(box inlet area))m

2

.

If the cycling persists after changing the supply deadbands,

check the heating and cooling prop bands to see if they are

greater than 4°F/-15.5°C. If not, increase the prop band values

to at least 4°F/-15.5°C and add an integration timer of 400.

Diagnose with HVAC PRO for Windows data graphing. If

present, reroute wire or use twisted pair and/or shielded cable.

Series fan is not running.

Unit is not in Occupied

mode.

Unit in initial startup.

Check HVAC PRO for Windows parameter table to ensure

occupied status shows on.

Before the series fan is commanded on, the damper fully

closes to ensure the fan does not turn backwards.

103F104F105FTroubleshooting

the VAV

Controller with

HVAC PRO for

Windows

Loading...

Loading...