RWF II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.610-IOM (JUN 11)

Page 12

• Remote – The external controller would reinitialize the

panel and proceed to run as required.

• Manual – The compressor will have to be restarted

manually after the 3phase bus fault has been cleared.

If the local power distribution system is unstable or prone

to problems, there are other recommendations to satisfy

these problems. If power spikes or low or high line voltages

are the problem, then we recommend the use of a Sola®

constant voltage (CV) transformer with a line suppression

feature. If a phase loss occurs, then you will typically get a

high motor amp shutdown. If problems continue to exist, then

an examination of the plant’s power factor may be in order.

Unless careful design failure analysis is considered in the

implementation of power systems, the alternative solutions

provide a safer and less expensive implementation. In either

case, only one Sola

®

may be used per compressor. Each

compressor needs to be individually isolated from each other

through a dedicated control transformer. Sharing a common

control power source is an invitation for ground loops and

the subsequent unexplainable problems.

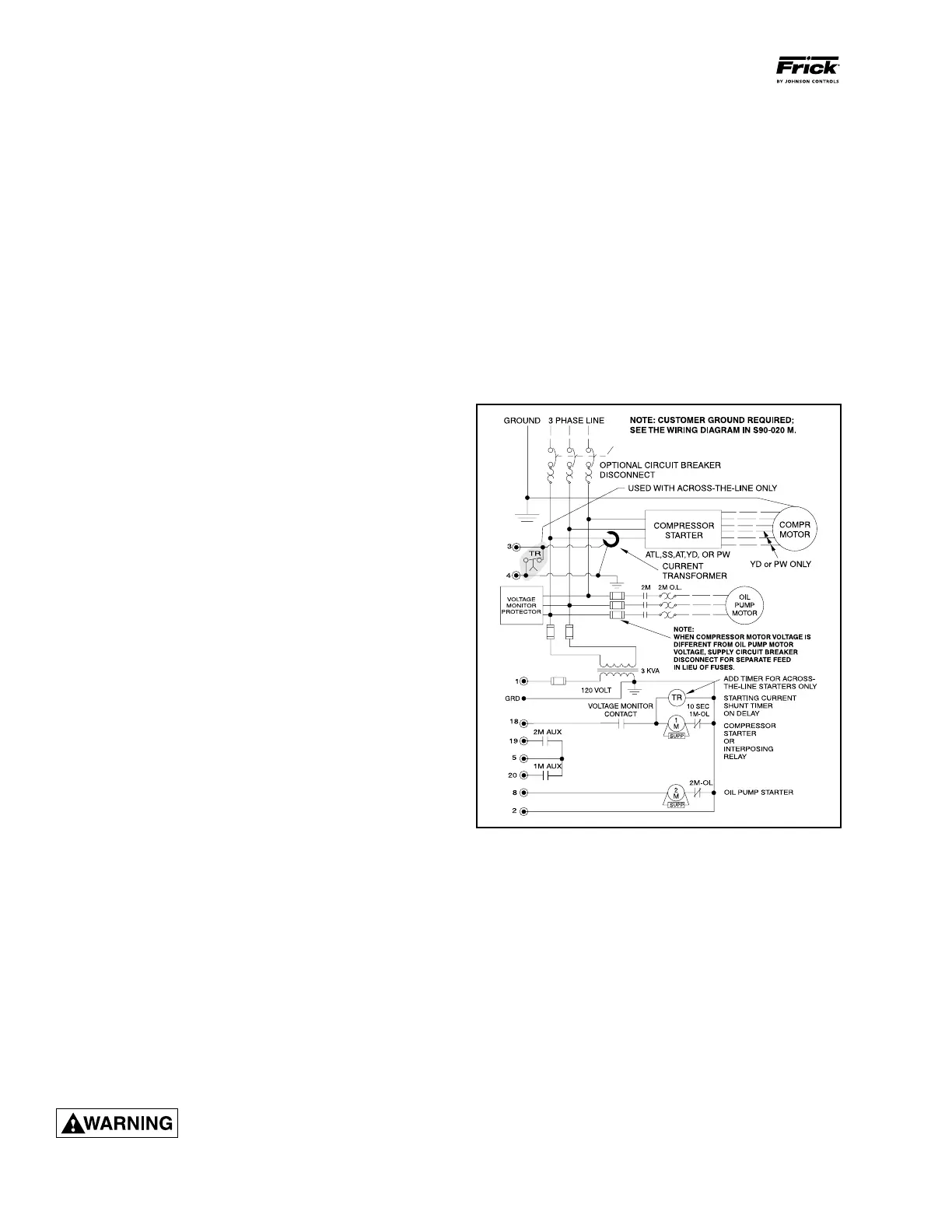

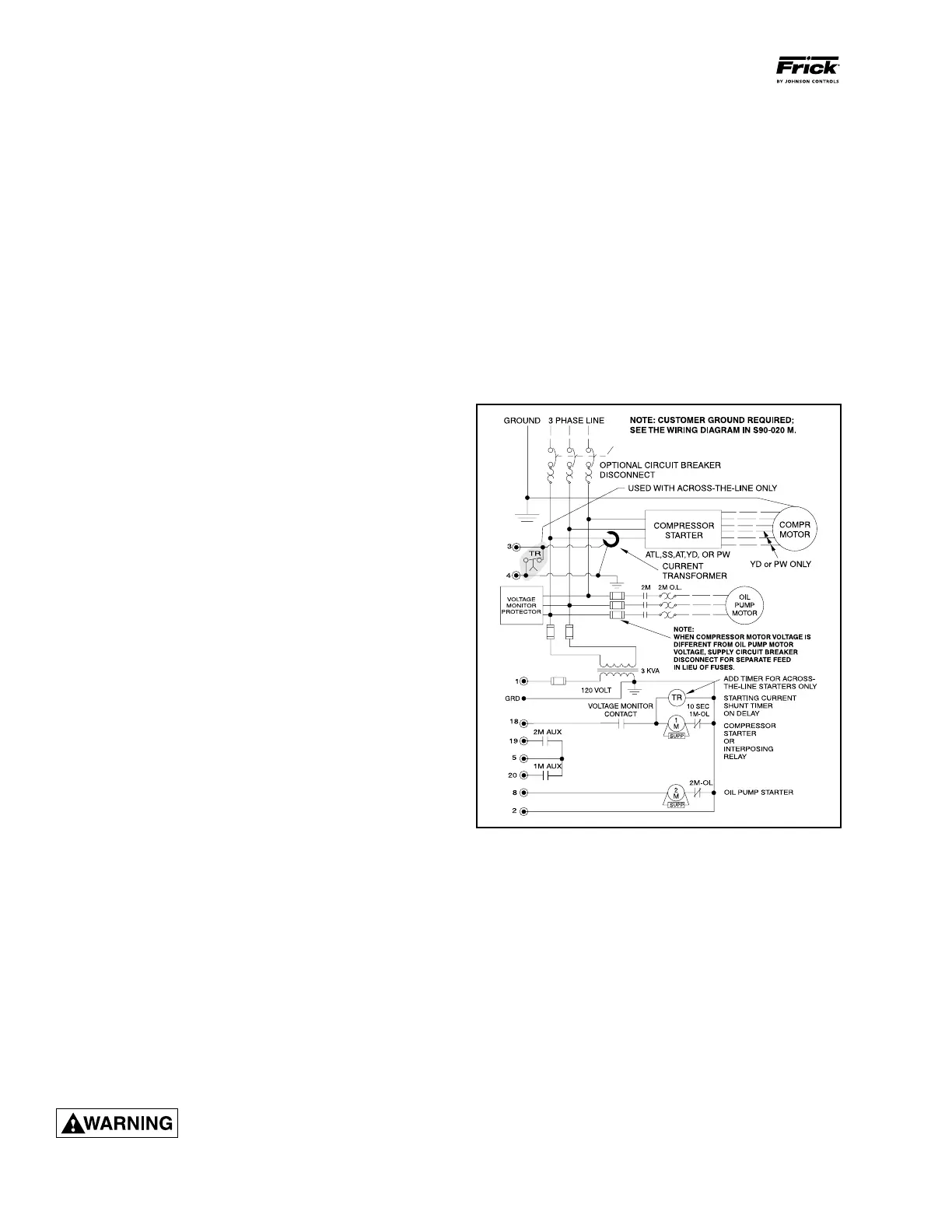

MOTOR STARTER PACKAGE

Motor starter and interlock wiring require ments are shown

in the Starter Wiring Diagram. All of the equipment shown

is supplied by the installer unless a starter package is pur

chased separately from Johnson ControlsFrick

®

. Starter

packages should consist of:

1. The compressor motor starter of the specied HP and

voltage for the starting method specied (acrosstheline,

wyedelta, or solidstate).

NOTE: If starting methods other than across-the-line are

desired, a motor/compressor torque analysis must be

done to ensure that sufcient starting torque is avail-

able, particularly in booster applica tions. Contact Johnson

Controls-Frick

®

if assistance is required.

2. If specied, the starter package can be supplied as a

combination starter with circuit breaker disconnect. Howev er,

the motor overcurrent protection/disconnection device can

be applied by others, usually as a part of an electrical power

distribution board.

3. The oil pump starter with fuses, or in the case where the

compressor motor is a different voltage from the oil pump

motor, with a circuit breaker disconnect suitable for sepa rate

power feed.

4. A 3.0 KVA control power transformer (CPT) to supply

120 volt control power to the microprocessor control sys

tem and separator oil heaters is included. If environ mental

condi tions require more than the usual two 500 watt oil

heaters, an appropriately oversized control transformer will

be required. If frequent power uc tuations are anticipat ed or

extremely noisy power lines are encoun tered, a regulating

control transformer should be considered. Contact Johnson

ControlsFrick

®

for assistance.

5. For customersupplied acrosstheline starters, a shunt

ing device must be installed across the Current Transformer

(terminals 3 & 4).

If the shunting device is not installed,

the Analog I/O board on the

Quantum

™

LX panel may be severely

damaged at start-up. See Figure 12.

6. One each normally open compressor motor and oil pump

motor starter auxiliary contact should be supplied. In addition

to the compressor and oil pump motor starter coils, the CT

and CPT secondaries should be wired as shown on the starter

package wiring diagram. The load on the control panel for

the compressor motor starter coil should not exceed a 2 amp

load. For larger starters, an interposing relay must be used

to switch the compres sor motor starter coil(s).

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

7. The compressor motor Current Transformer (CT) is in

stalled on any one phase of the compressor leads.

NOTE: The CT must see all the current of any one phase,

therefore in wye-delta applications BOTH leads of any

one phase must pass through the CT.

Figure 12 - Starter Wiring Diagram

Loading...

Loading...