RWF II ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.610-IOM (JUN 11)

Page 9

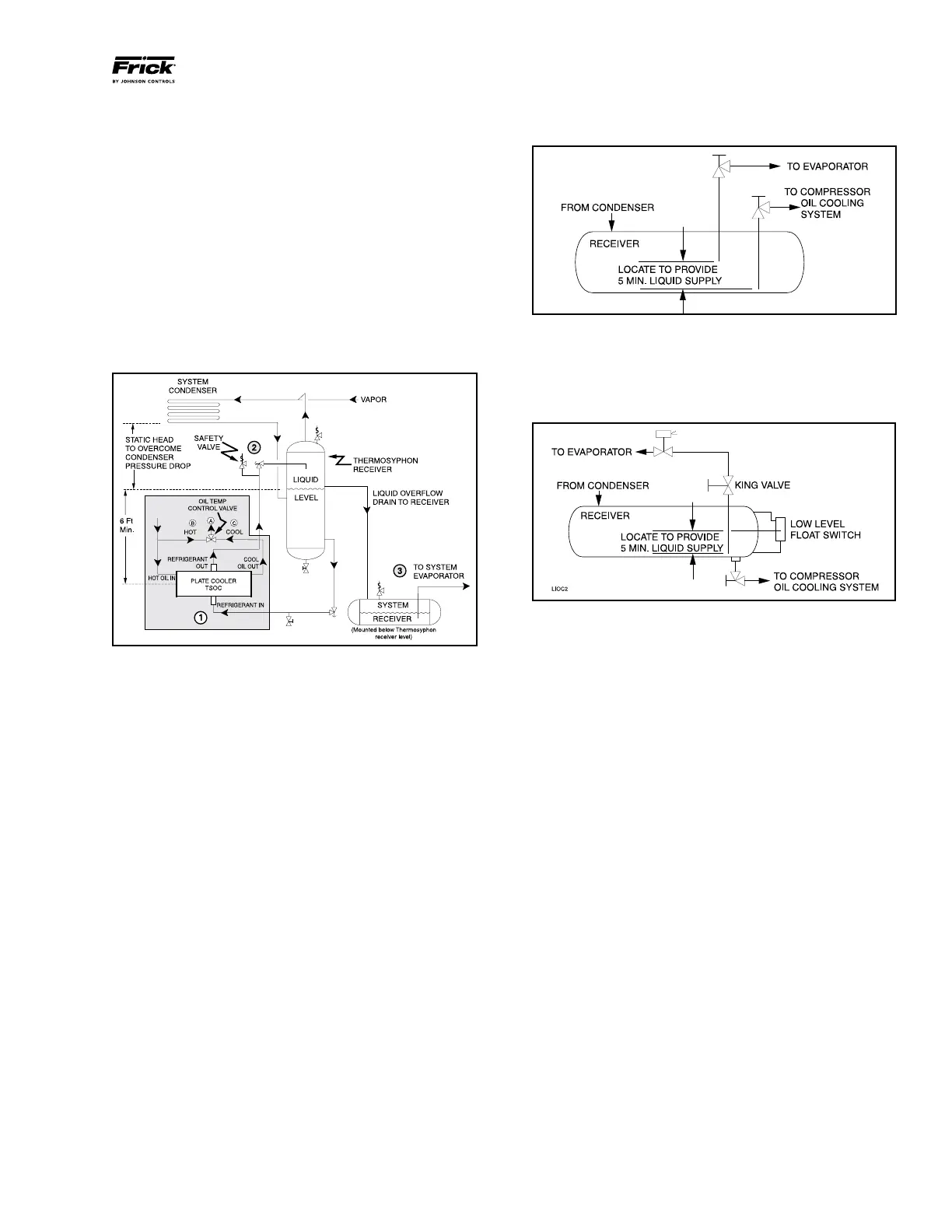

ator tube to ensure continued oil cooling when the receiver

level is low.

Figure 6 - Dual Dip Tube

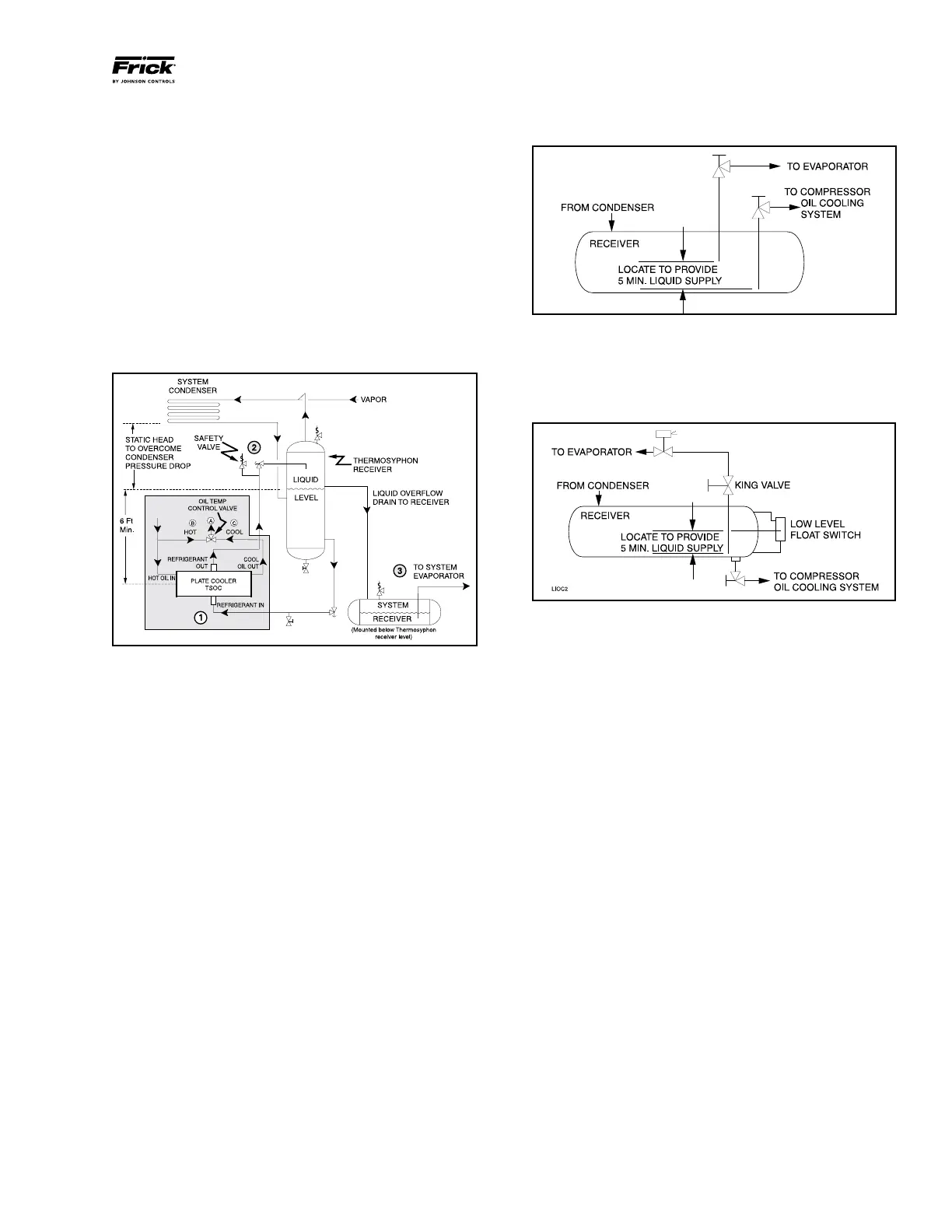

The level-control method (Figure 7) utilizes a float level

control on the receiver to close a solenoid valve feeding the

evaporator when the liquid falls below that amount necessary

for 5 minutes of liquid injection oil cooling.

Figure 7 - Level Control

LIQUID LINE SIZES/RECEIVER VOLUME

Liquid line sizes and the additional receiver volume (quanti-

ty of refrigerant required for 5 minutes of liquid injection oil

cooling) are given in TABLE 1.

WATER-COOLED OIL COOLING (OPTION AL)

The plateandshell type watercooled oil cooler is mounted

on the unit complete with all oil piping. The customer must

supply adequate water connections. Determine the size of

the watercooled oil cooler supplied with the unit, as outlined

on the Frick P&I diagram and arrangement drawings. The

water supply must be sufcient to meet the required ow.

A closedloop system is recommended for the waterside of

the oil cooler. Careful attention to water treatment is es

sential to ensure adequate life of the cooler if cooling tower

water is used. It is imperative that the condition of cooling

water and closed-loop uids be analyzed regularly and

as necessary and maintained at a pH of 7.4, but not less

than 6.0 for proper heat exchanger life. After initial start

up of the compressor package, the strainer at the inlet of

the oil cooler should be cleaned several times in the rst 24

hours of operation.

In some applications, the plate and shell oil cooler may be

subjected to severe water conditions, including high tem

perature and/or hard water conditions. This causes acceler

ated scaling rates which will penalize the performance of the

heat exchanger. A chemical cleaning process will extend the

life of the Plate and Shell heat exchanger. It is important to

establish regular cleaning schedules.

Cleaning: A 3% solution of Phosphoric or Oxalic Acid is rec

ommended. Other cleaning solutions can be obtained from

outside of the shaded area on the piping diagram with con

sideration given to the following:

1. The refrigerant source, thermosyphon or system receiv er,

should be in close proximity to the unit to minimize piping

pressure drop.

2. The liquid level in the refrigerant source must be 6 to 8

feet minimum above the center of the oil cooler.

3. A safety valve should be installed if refrigerant isolation

valves are used for the oil cooler.

NOTE: The component and piping arrangement shown in

Figure 5 is intended only to illustrate the operating principles

of thermosyphon oil cooling. Other component layouts may

be better suited to a specic installation. Refer to publica-

tion 070-900E for additional information on Thermosyphon

Oil Cooling.

Figure 5 - TSOC Piping Arrangement

1. The thermosyphon oil cooler is supplied with oil side

piped to the compressor unit and stub ends supplied on the

refrigerant side.

2. A refrigerantside safety valve is required in this location

only when refrigerant isolation valves are installed between

the cooler and thermosyphon receiver. If no valves are used

between the cooler and TSOC receiver, the safety valve on

the TSOC receiver must be sized to handle the volume of

both vessels. Then, the safety valve on the cooler vent (liquid

refrigerant side) can be eliminated.

3. The system receiver must be below the thermosyphon

receiver in this arrangement.

LIQUID INJECTION OIL COOLING (Optional)

The liquid injection system provided on the unit is self

contained but requires the connection of the liquid line sized

as shown in Table 1.

It is IMPERATIVE that an uninterrupted supply of high pres

sure liquid refrigerant be provided to the injection system

at all times. Two items of EXTREME IMPOR TANCE are the

design of the receiver/liquid injection supply and the size of

the liquid line.

It is recommended that the receiver be oversized sufcient ly

to retain a 5minute supply of refrig erant for oil cooling. The

evaporator supply must be secondary to this consideration.

Two methods of accomplishing this are shown.

The dual dip tube method (Figure 6) uses two dip tubes in

the receiver. The liquid injection tube is below the evapor

Loading...

Loading...