JOHNSON CONTROLS

8

FORM 130.13-NOM1 (114)

MAINTENANCE

Optional Damper Actuator

An optional factory mounted oating type actuator

is available, which mounts directly to the damper

operating shaft. The actuator is not provided with and

does not require any limit switches but is electronically

protected against overload.

Manual Override

A button on the side of the actuator cover disengages

the gear train so the drain shaft can be moved manually.

Releasing the button will re-engage the gear train.

Mechanical Angle of Rotation Stops

The adjustable stops may be field adjusted to halt

the rotation of the damper blade before the damper

blade reaches the damper stops. The actuator can be

indenitely stalled in any position without harm.

1. Loosen the two end stop screws using a No. 2

Phillips head screwdriver, being careful not to

unscrew the captive nut under the slot.

2. Move the stops (in 2.5° steps) to the desired posi-

tion and retighten the screws.

External Terminal Strip

The external terminal strip is located on the top of the

actuator. Connections are numbered. The terminals

are designed for 26 to 16 gauge wires. For most

installations, 18 or 16 gauge wire will work well with

the actuator (see table 5 for maximum wire lengths).

Overload Protection

The actuators are electronically protected against

mechanical overload. In the actuator, an electronic

circuit maintains the current at a level that will not

damage the motor while providing adequate holding

torque.

Checkout Instructions

1. Disconnect actuator from the controller.

2. Apply 24 VAC to the COM and CW terminals on

the actuator. Actuator should rotate in a clockwise

direction.

3. Apply 24 VAC to the COM and CCW terminals on

the actuator. Actuator should rotate in a counter

clockwise direction.

4. If actuator moves in both directions, it is opera-

tional.

5. If the actuator does not rotate, it may be at an end

stop or there is a problem with the damper.

6. Loosen the set screw to free the actuator from the

damper shaft. Check to make sure that the damper

shaft rotates freely.

7. Check to make sure that actuator is not against

stop. Repeat steps 2 and 3.

8. If actuator does not rotate, replace.

Damper Shaft

There is an indicator on the end of the damper shaft that

can be used to determine the position of the damper

blade. If the indicator is horizontal, the damper is

completely open. The damper shaft is ½" diameter.

Coil

The frequency of required cleaning is dependent on the

operating hours of the system, lter maintenance and

efciency as well as dirt load.

Important: Coils may become exter-

nally dirty as result of normal opera-

tion. Dirt on the surface of the coil

reduces its ability to transfer heat that

can result in reduced performance,

and increased operating energy cost.

If the dirt on the surface of the coil

becomes wet, microbial growth (mold)

can result, possibly causing unpleas-

ant odors and serious health related

indoor air quality problems.

Fin edges are sharp. Fins are fragile;

care must be exercised to avoid damag-

ing ns. Do not use solutions to clean

coils; drain pans are not present to

remove collected solution.

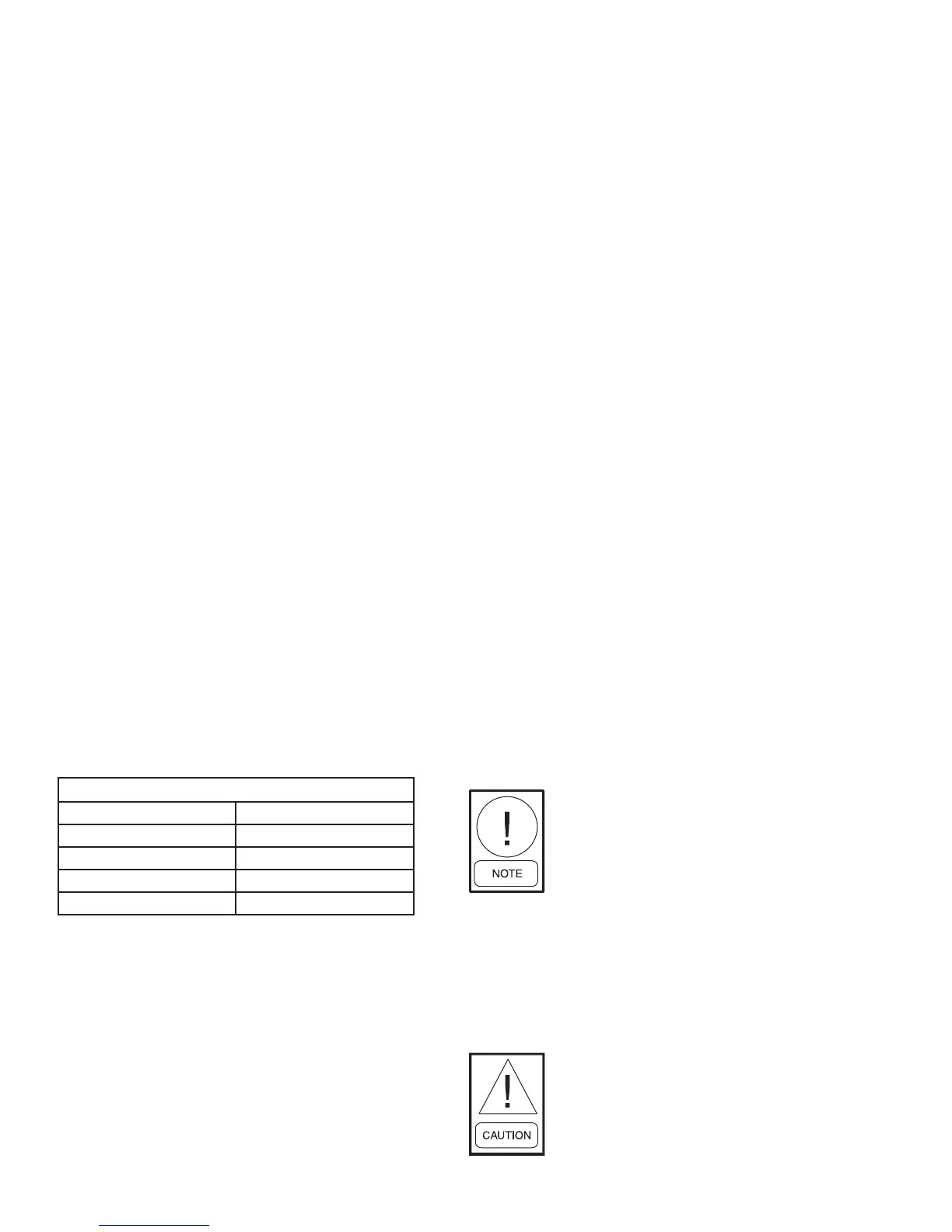

TABLE 5 - MAXIMUM WIRE LENGTHS

WIRE SIZE MAX FEET

16 GA 1225 FT

18 GA 725 FT

20 GA 400 FT

22 GA 200 FT

Loading...

Loading...