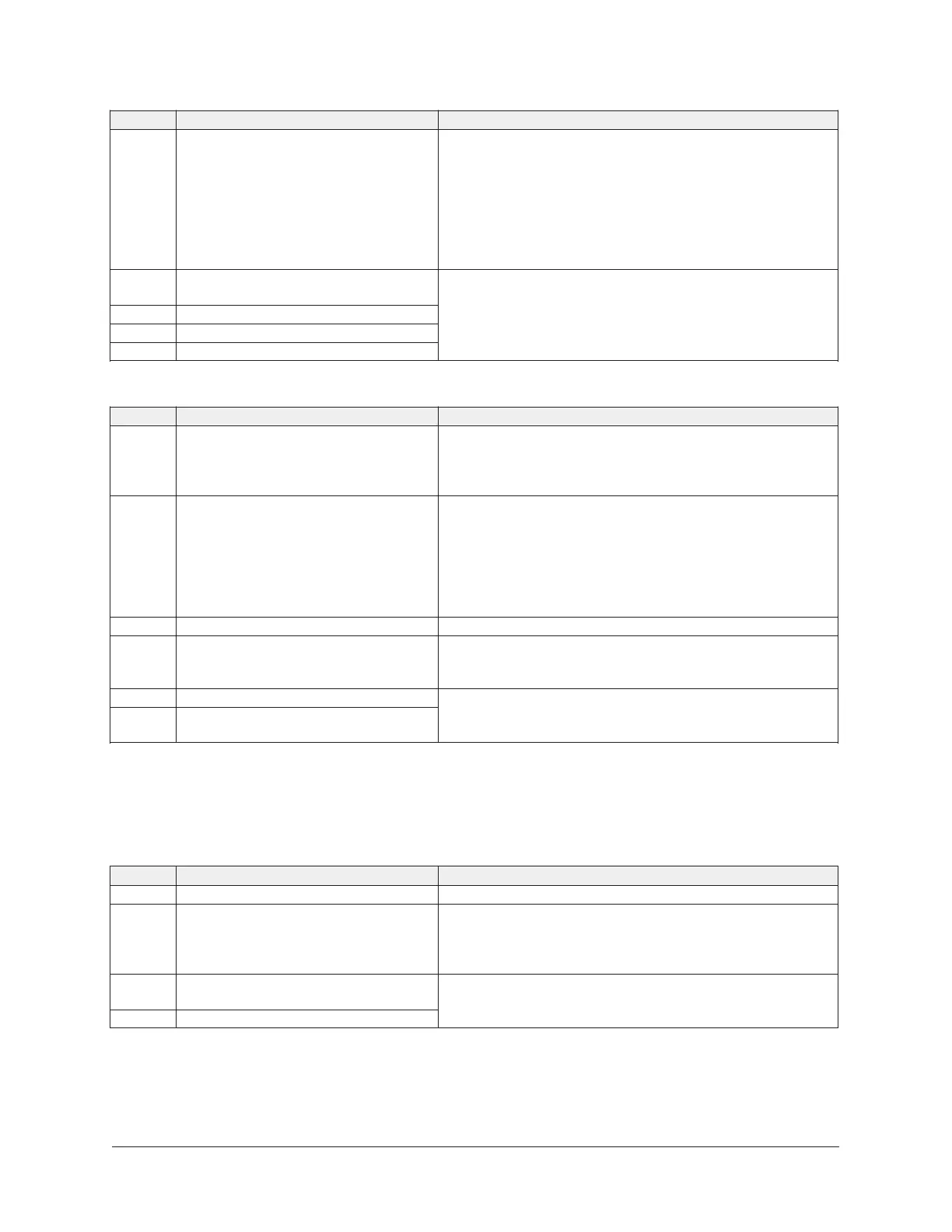

Table 34: Troubleshooting the high temperature generator

Item Cause Countermeasure

3 Non-condensable gas stays in machine.

• See Purge procedure.

• Check the capacity of the vacuum pump.

• Check the purge unit for trouble.

• Purge air from the absorption chiller.

• If partial-load operation is continued for a long period, non-

condensable gas tends to stay in the absorber. In this case,

purge directly from the low-pressure side (absorber).

4

Heat exchange tube is dirty (Chilled water,

cooling water).

5 Solution is crystallized.

6 Corrosion inhibitor is worn.

7 Air leaks in absorption chiller.

Contact your local Johnson Controls Service Office.

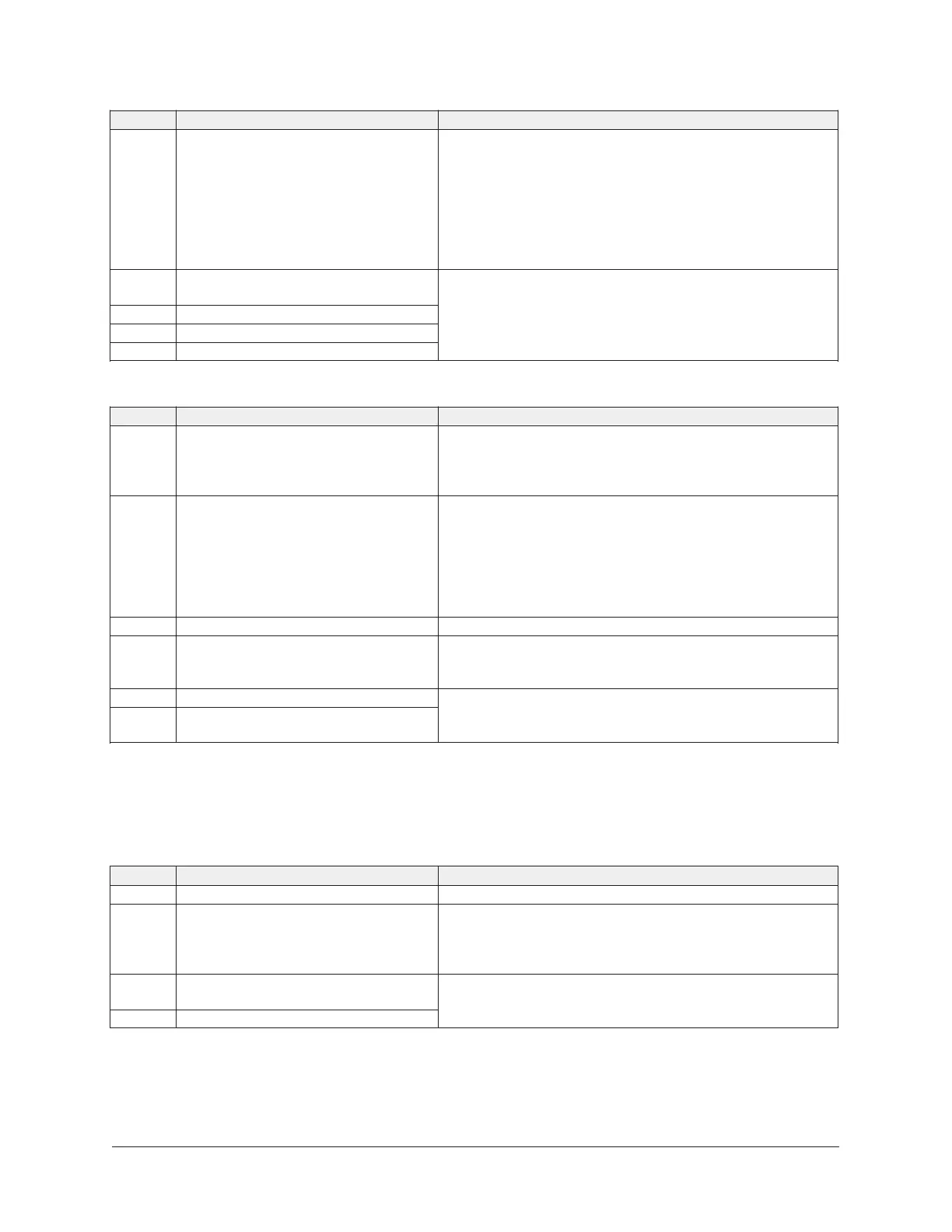

Table 35: Chilled water overcooling or refrigeration overcooled

Item Cause Countermeasure

1

Chilled water flow rate lowers or changes

sharply.

Check if the chilled water flow rate changes suddenly (particularly in

the case of variable flow rate specification). If it changes suddenly,

apply a limit of the change rate to the chilled water flow control or

take another measure.

2

Cooling water temperature at inlet changes

sharply.

Check if the cooling water temperature at inlet changes sharply

(by checking start and stop of the fan). If the chilled water or the

refrigerant temperature is low, the chiller stops immediately but

does not perform the dilution operation. If left as it is, the solution

can crystallize in 4-5 hours. To prevent this, dilute the solution

according to the procedure shown in Manual refrigerant blowdown

and diluting method.

3 Load lowers sharply. Check if the load changes sharply.

4 Refrigerant is dirty (contains solution).

Check if the refrigerant refining operation has been performed

periodically. For the refrigerant refining method, see Refrigerant

refining method.

5 Heat exchange tube is dirty (chilled water).

6

Temperature controller or safety switch is

broken.

Contact your local Johnson Controls Service Office.

In the case of chilled water suspension, the absorption chiller does not perform diluting operation

but stops immediately. If the absorption chiller is left as it is, the solution in it can crystallize in 4-5

hours. To prevent this, dilute the solution according to “manual refrigerant blowing and diluting

method”.

Table 36: Chilled water suspension

Item Cause Countermeasure

1 Chilled water pump has a problem. Check the chilled water pump for a problem.

2 Chilled water flow rate is low.

Check to see if the chilled water flow rate is lower than the setpoint

of the water suspension switch. If it is low, check the flow controller,

check the strainer for clogging, and check the opening ratio of the

flow control valve.

3

Pressure transfer pipe of water suspension

switch is clogged.

4 Water suspension switch is broken.

Contact your local Johnson Controls Service Office.

If the chiller has a pump problem, it does not perform the diluting operation but stops immediately.

If left as it is, the solution in it can crystallize in 4-5 hours. To prevent this, contact your local Johnson

Controls Service Office immediately.

YHAU-C Single Effect Steam-Fired Absorption Chiller170

Loading...

Loading...