5566019-BIM-B-1118

Johnson Controls Ducted Systems 63

Calculating the cubic feet of gas consumed per hour

1. To find the BTU input, multiply the number of cubic feet of

gas consumed per hour by the BTU content of the gas in

your particular locality.

Note: The BTU content of gas varies widely from area to

area, contact your gas company for this information.

By actual measurement, it takes 19 seconds for the hand

on a 1 cubic foot dial to make a revolution with a 192,000

BTU/h furnace running.

2. To determine rotations per minute, divide 60 by 19 = 3.16.

3. To calculate rotations per hour, multiply 3.16 60 = 189.6.

4. Multiply 189.6 1 (0.5 if using a 1/2 cubic foot dial) = 189.6.

5. Multiply 78 (the BTU rating of the gas). For this example,

assume the gas has a BTU rating of 1050 BTU/ft.

3

.

The result of

199,000

BTU/h is within 5% of the

192,000

BTU/h rating of the furnace.

Adjusting the manifold gas pressure

This gas furnace has two heat stages. The gas valve has two

adjustment screws located under a plastic protective cover. The

second stage (100% input) adjustment screw is adjacent to the

HI marking on the valve. The first stage (60% input) adjustment

screw is located adjacent to the LO marking on the valve (see

Figure 33).

Adjust the second stage (100% input) pressure first, then adjust

first stage (60% input) pressure.

1. Turn off electrical power to the unit.

2. Using the outlet pressure port on the gas valve, connect a

manometer to monitor the manifold pressure.

3. Remove the plastic cap that covers the HI and LO pressure

adjustment screws.

4. Turn on electrical power to the unit.

5. Set the thermostat to call for second stage heat and start

the furnace.

6. If necessary, use a screwdriver to turn the

second stage

adjustment screw clockwise to increase manifold pressure

or counterclockwise to decrease manifold pressure.

Note: Do not over-fire the unit on second stage.

7. After you check the high manifold pressure, adjust the

thermostat to call for first stage heat.

8. If necessary, use a screwdriver to turn the first stage

adjustment screw clockwise to increase manifold pressure

or counterclockwise to decrease manifold pressure.

Note: Do not under-fire the unit on first stage.

9. After you check the pressure, replace the plastic cap

covering the HI and LO pressure adjustment screws.

Note: When using natural gas, the manifold pressure for

second stage (100% input) is 3.5 IWG ± 0.3. The

manifold pressure for first stage (60% input) when

using natural gas is 1.5 IWG ± 0.3.

Adjusting the temperature rise

The temperature rise is the difference of temperature between

the return air and the heated air from the furnace. The

temperature rise must lie within the range shown on the CSA

rating plate and the data in Table 14.

1. After about 20 minutes of operation, determine the furnace

temperature rise. Take readings of both the return air and

the heated air in the ducts (about 6 feet from the furnace)

where they are not affected by radiant heat.

2. After you determine the temperature rise, calculate the

CFM according to the following formula.

3. Increase the blower CFM to decrease the temperature rise.

Decrease the blower CFM to increase the rise (see Supply

air drive adjustment on page 54).

Note: Each gas heat exchanger size has a minimum

allowable CFM. Below this CFM, the limit opens.

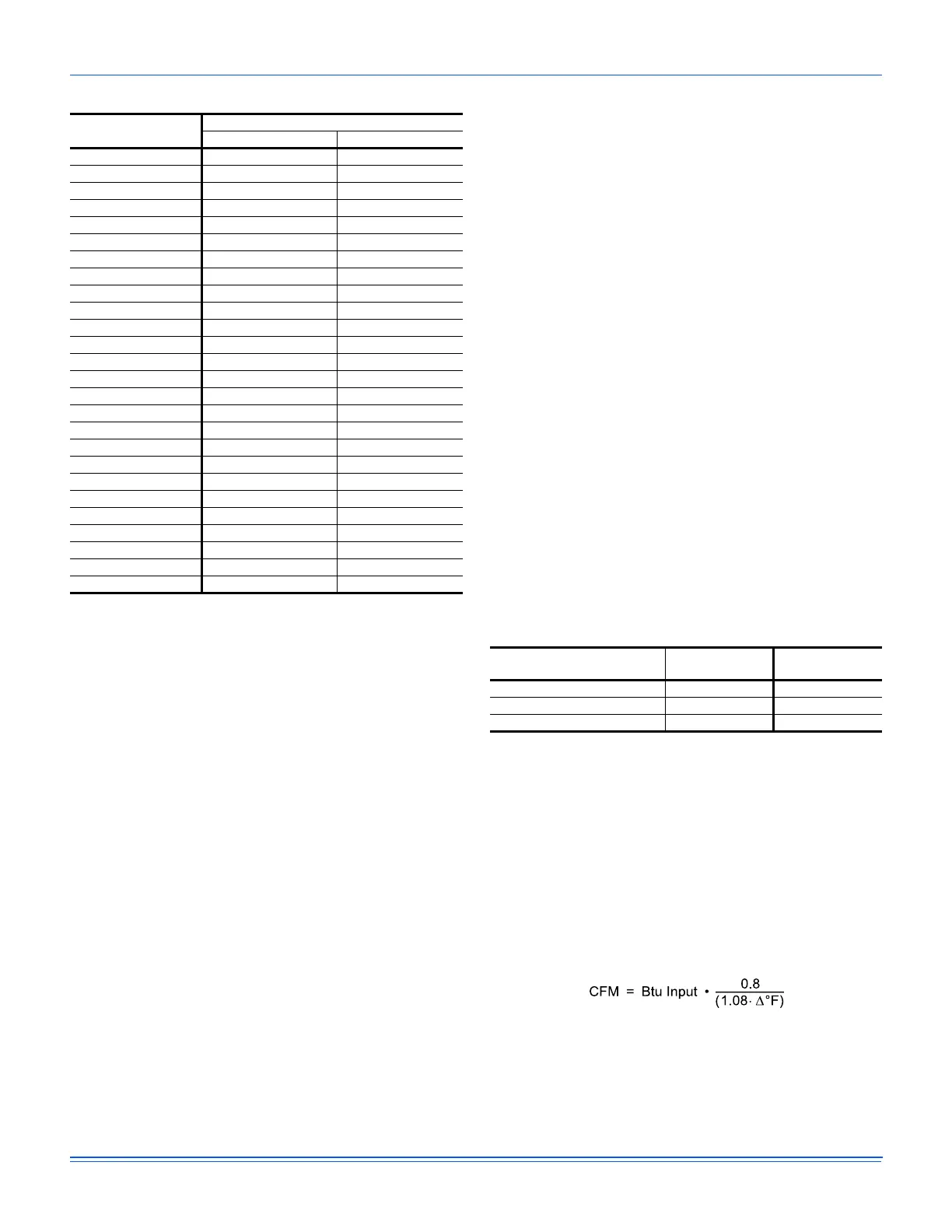

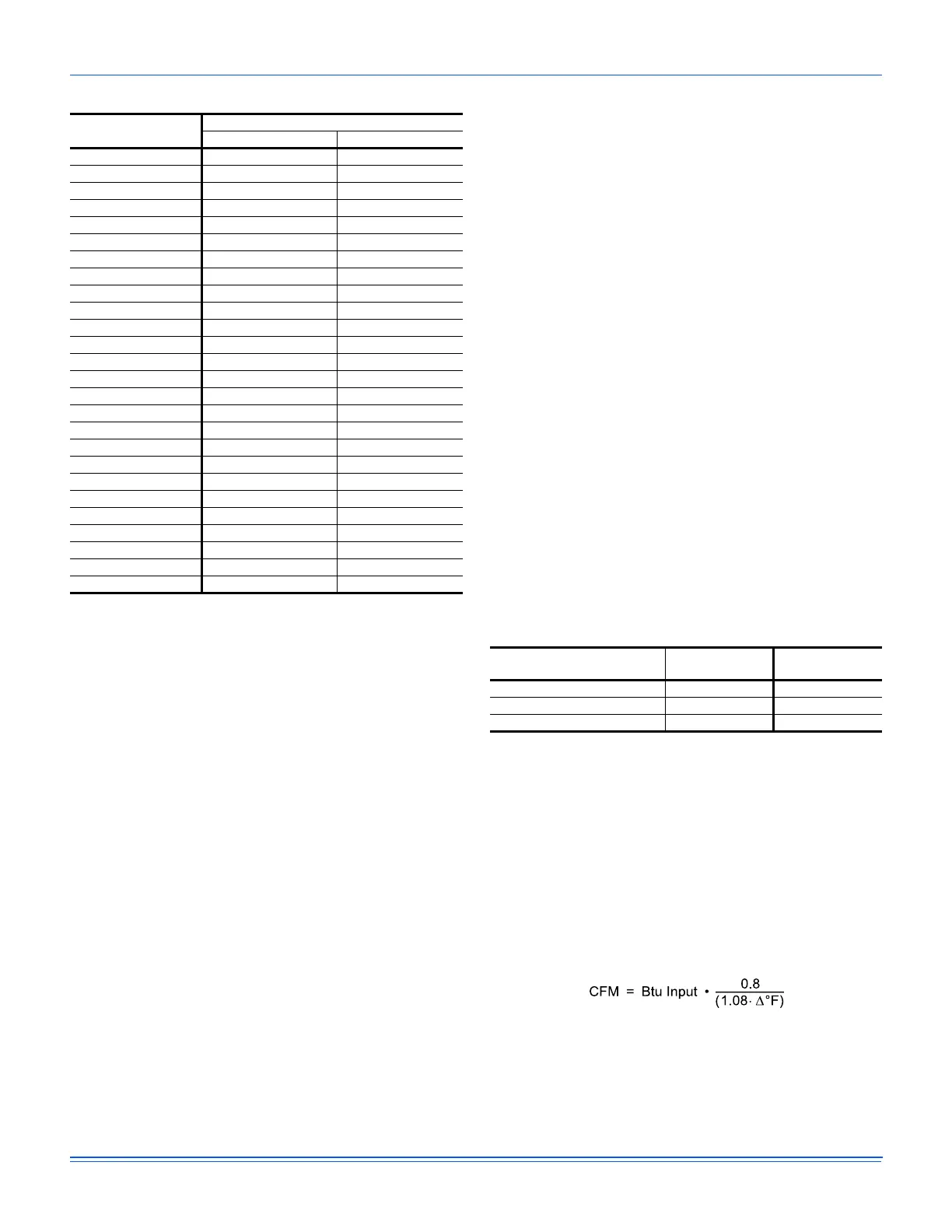

Table 32:Gas rate cubic feet per hour

Seconds for one

rev.

Size of test dial

1/2 cu. ft. 1 cu. ft.

10 180 360

12 150 300

14 129 257

16 113 225

18 100 200

20 90 180

22 82 164

24 75 150

26 69 138

28 64 129

30 60 120

32 56 113

34 53 106

36 50 100

38 47 95

40 45 90

42 43 86

44 41 82

46 39 78

48 37 75

50 36 72

52 35 69

54 34 67

56 32 64

58 31 62

60 30 60

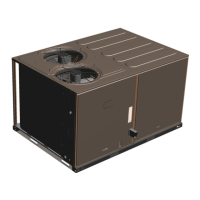

Table 33:Gas heat stages

No. of burner tubes

2nd stage input

(100% BTU/h)

1st stage input

(60% BTU/h)

4 120,000 72,000

6 180,000 108,000

8 240,000 144,000

Loading...

Loading...