V Range 502 l 652 l 802 Maintenance Manual

MA6:4

Chapter - Wearing Items

These parts are also abraded by the material being conveyed from the suction nozzle and must be periodically

inspected and replaced when worn or holed. The duct is 250 mm diameter.

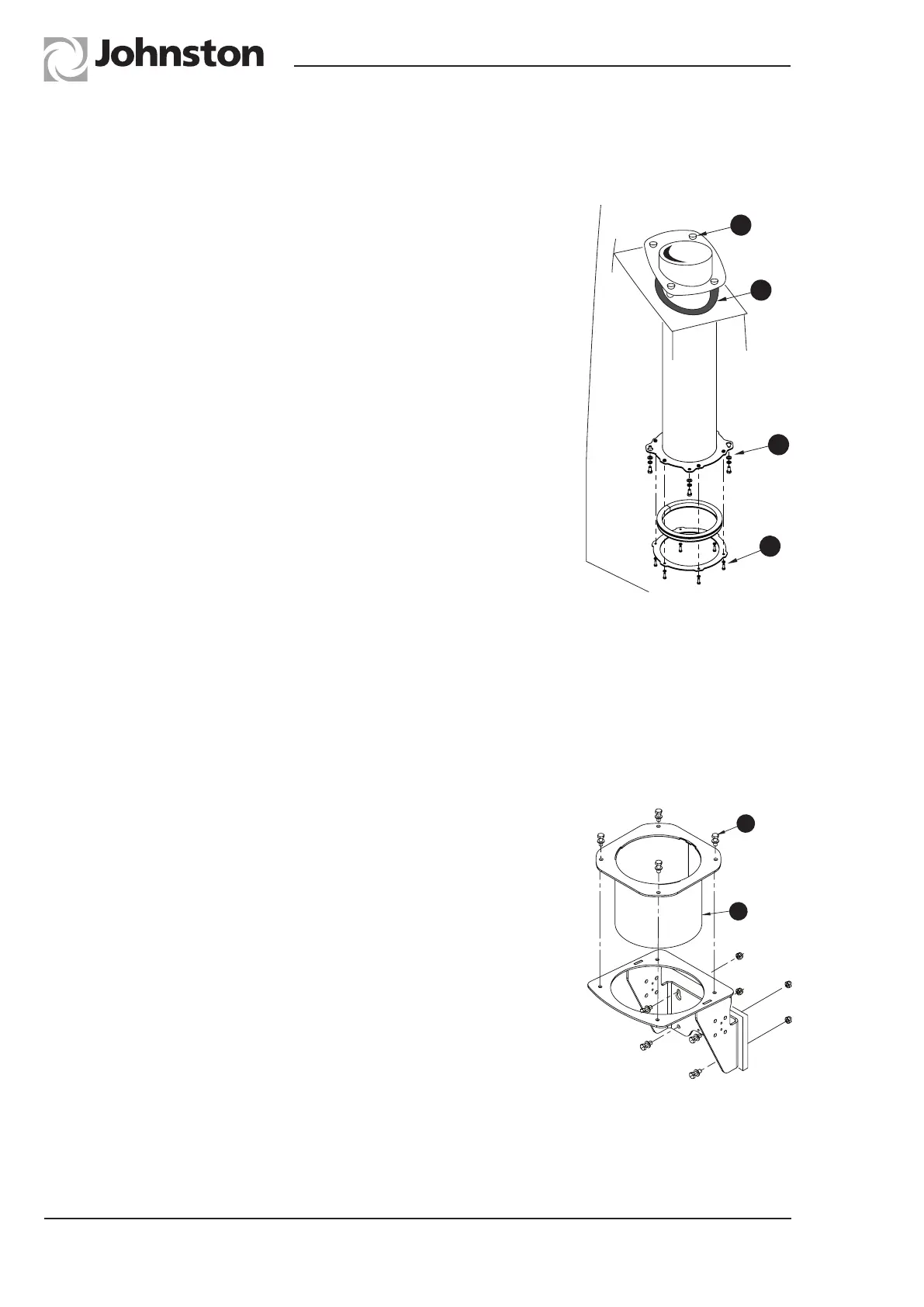

Removal

Enter body after carrying out the same precautions as for intake flap

replacement. Remove the four screws securing the collar around the

intake duct (A). Lift up the flap manually (if fitted) and remove collar.

A rubber cord (B) will now be visible which should also be removed

with care to prevent damage. Dismount from body. Tip body and

support on prop. Remove the six screws (D) securing the make/break

rubber seal retention flange. (This seal assembly can be kept intact

for re-fitment to the replacement intake duct unless deemed requiring

replacement too.) Release two of the screws (C) in the key-holed

intake duct flange and remove the other two. Twist the intake duct so

the two released screws pass through the larger part of the keyhole

and remove the duct.

Refitting

Reverse of removal procedure. Align slots in the intake duct flange

with the released screws and twist. Fit the other two bolts and tighten.

Re-fasten the make/break seal assembly to the intake duct flange

with six screws. Replace the rubber cord and collar plate inside the

body and secure by fully tightening the four duct top retaining bolts.

M02MA-022

D

A

B

C

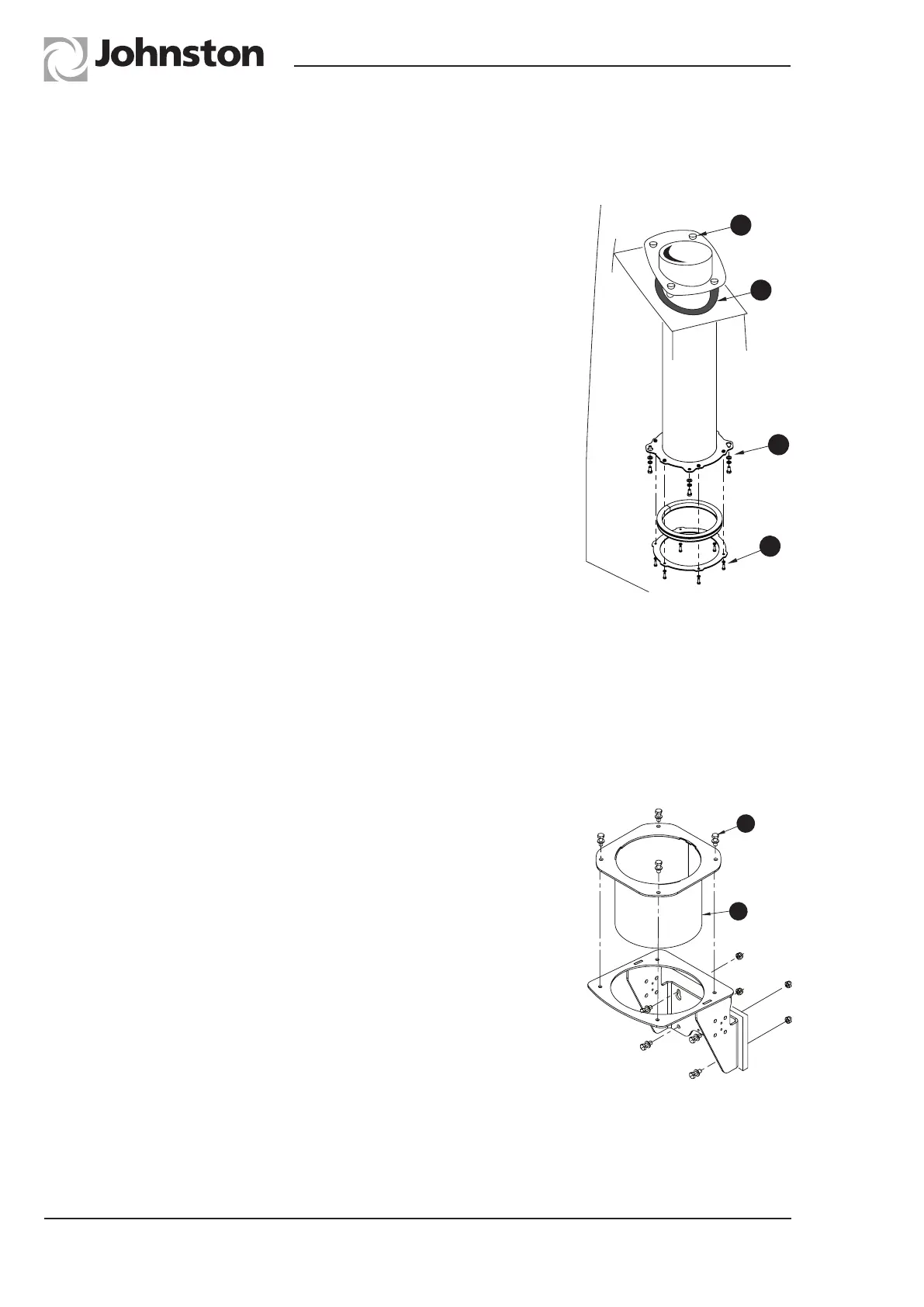

Intake Seat

Removal

Raise the body and ensure the body prop is engaged in the rack.

Release trunking from tube as described on previous page.

Remove the four bolts (A). Lift seat (B) clear of bracket.

Refitting

Reverse of removal procedure. As no adjustment for seal compression

is provided, it is wise to check seal compression when the body is

lowered.

Intake Duct

M02MA-021

A

B

Intake Trunking

Removal

Lower suction nozzle to the ground, release worm drive clips at either end and remove flexible trunking.

The nozzle trunking has an inside diameter of 250mm.

Refitting

Loosely fit worm drive clips to either end of trunking. Engage trunking onto the nozzle with a 55 mm

(2”) overlap and tighten clip. Fit other end to the intake seat and secure. Check trunking is not twisted

or rucked and does not foul anything when the nozzle is raised or lowered again.

Loading...

Loading...