109

8

502 51 61-01

A

B

C

DA

502 50 30-13

502 50 30-14

Mod. 2077

Mod. 2083

Crankshaft and crankcase

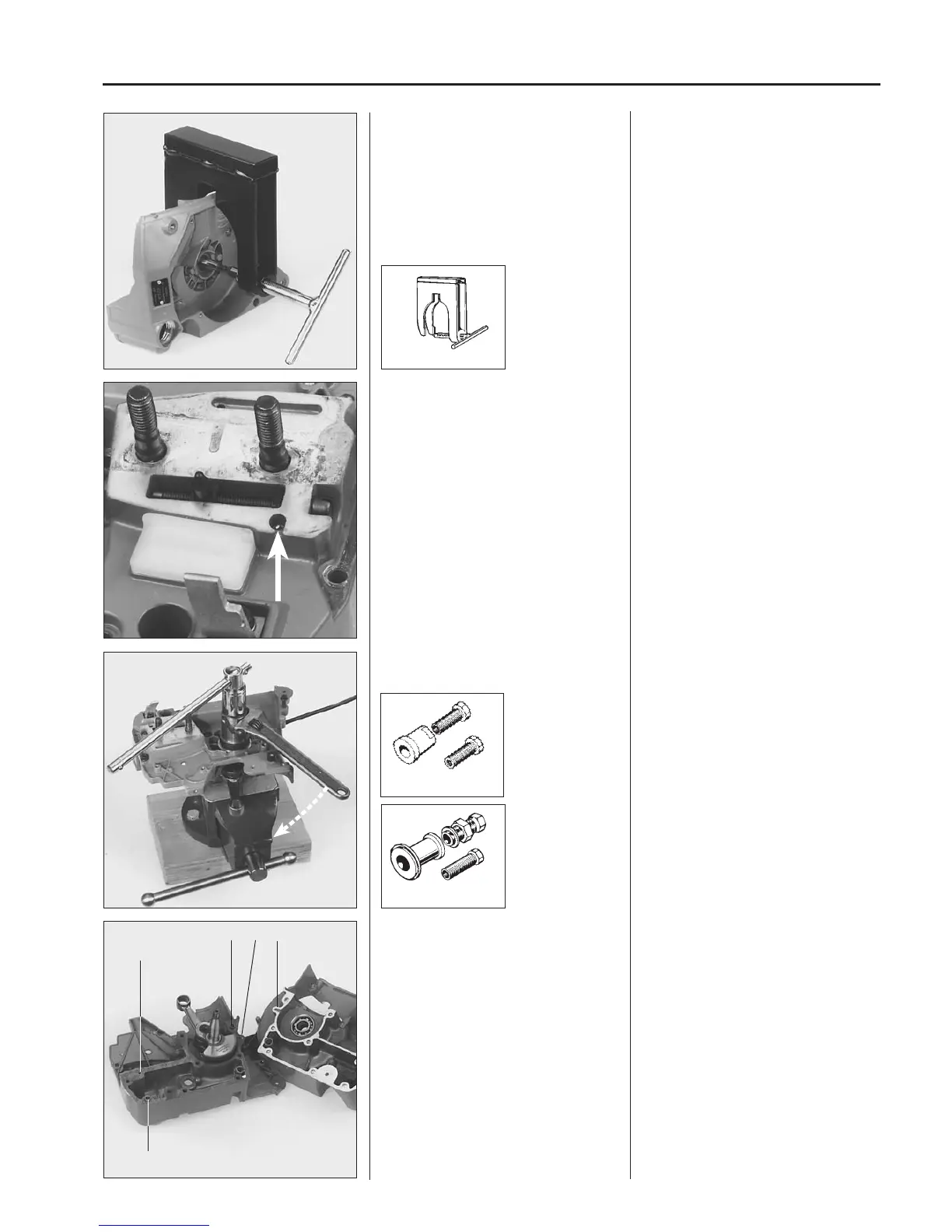

Press out the crankshaft from the flywheel

side’s crankcase half.

Dismantle the ball bearings and sealing

rings.

Clean the crankcase halves and check

that the oil tank vent functions.

Fitting

Fit new ball bearings.

Place a new gasket on the clutch side’s

crankcase half and check that it has holes

for the oil tank vent and impulse passage.

Press out the crankshaft from the flywheel

side’s crankcase half with tool

502 51 61-01.

Inspect the crankshaft as per chapter

”Checking of crankshaft”.

Heat the crankcase halves and dismantle

the ball bearings and sealing rings in the

same way as described for mod. 625/

630/670.

Clean the sealing surfaces of the crank-

case halves from gasket residue.

Check that the hole for the oil tank vent is

not blocked and that the split pin is in

position.

Fitting

Fit new ball bearings.

Use the same method for both crankcase

halves as described for mod. 625/630/

670.

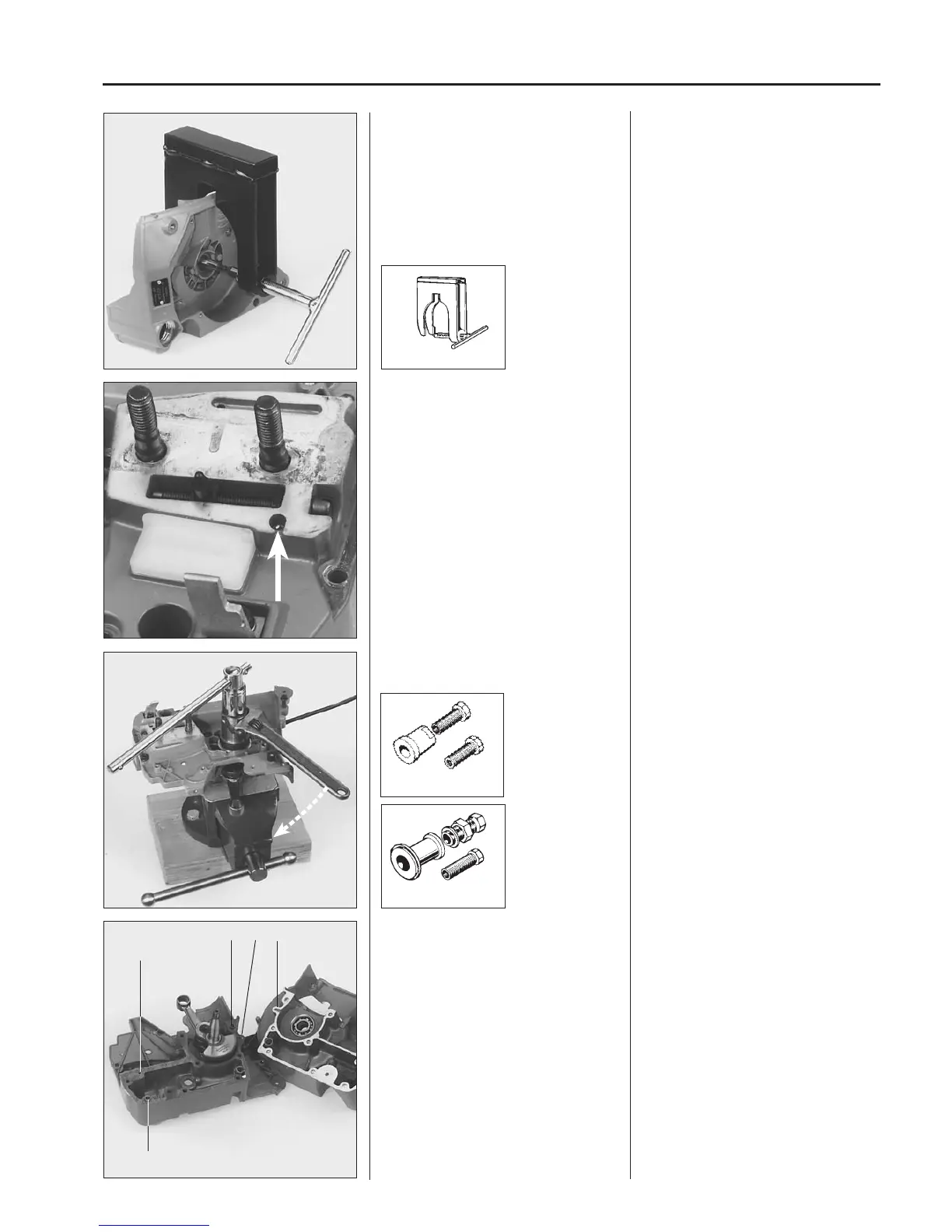

Push the crankshaft into the clutch side’s

crankcase half and put the sealing ring in

position.

Press in the sealing ring and crankshaft

by means of tool 502 50 30-13 (mod.

2077) and 502 50 30-14 (mod. 2083).

Make sure that the connecting rod is not

jammed against the crankcase.

Place a new gasket on the flywheel side’s

crankcase half. If necessary fix it in posi-

tion with a little grease.

Check that both guide sleeves (A) are in

position.

Check that the gasket has a hole (B) for

the oil tank vent and a hole (C) for the

impulse passage. Make sure that the

groove (D) in the crankcase half is not

blocked.

Loading...

Loading...