56

5

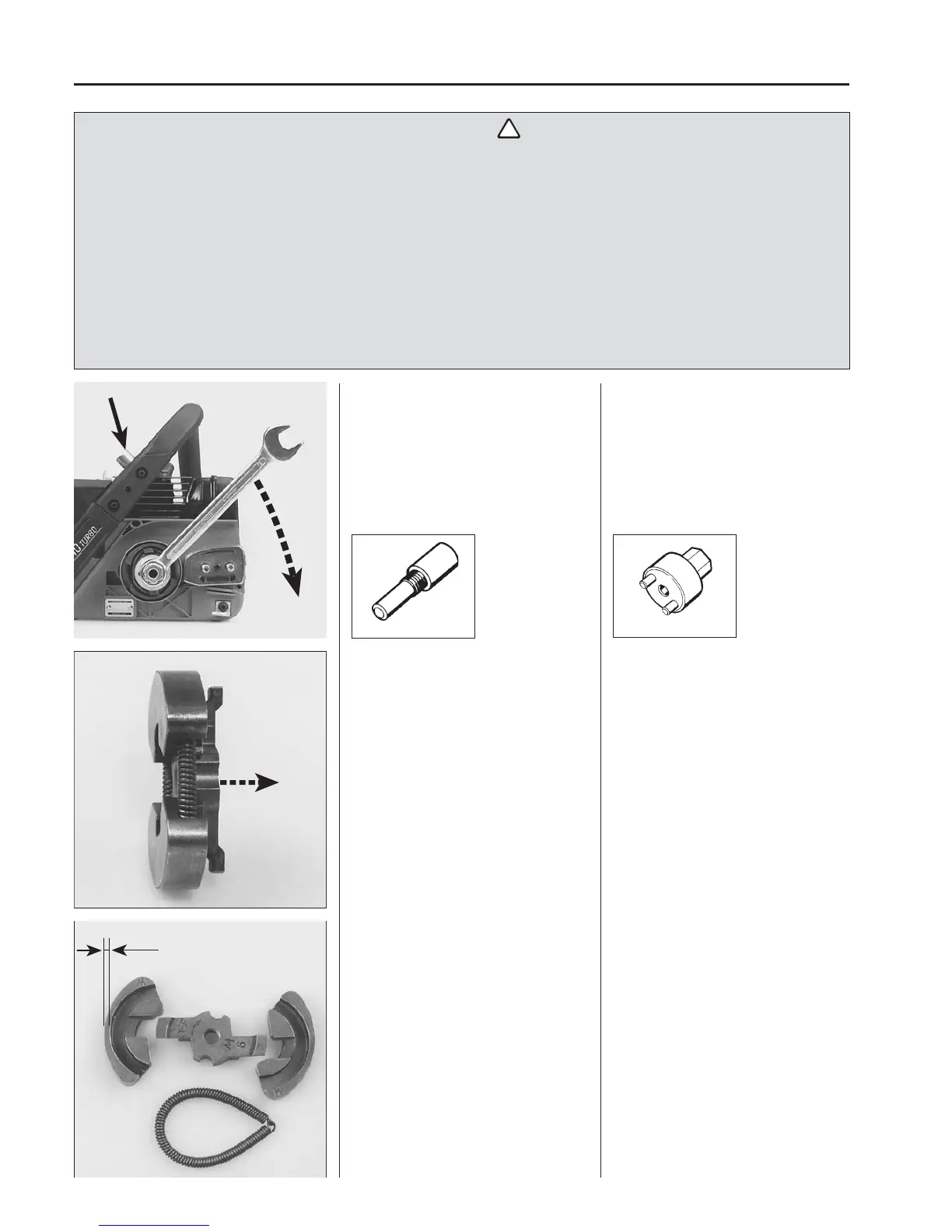

502 50 33-01

530 03 11-12

min. 1 mm

Centrifugal clutch

The centrifugal clutch has the purpose of transferring

the power between the engine and the cutting equipment.

As the name implies it works according to the centrifu-

gal principle.

This principle implies that the clutch’s friction shoes are

slung outwards towards the clutch drum at a specific

engine speed. When the friction against the drum

becomes sufficient it is driven round at the same speed

as the engine.

WARNING!

Never start or test run the engine if the clutch

cover is removed. The clutch can come loose

and cause personal injury.

There is a certain degree of slip between the

clutch and the clutch drum during acceleration,

but also in the reverse case if the cutting

equipment should stick. This avoids irregular

load alternations on the crankshaft.

The engagement speed is carefully tested so that

the engine can run at idling speed without the

cutting equipment rotating.

!

Dismantling mod. 2036/2040

Dismantle the clutch from the crankshaft.

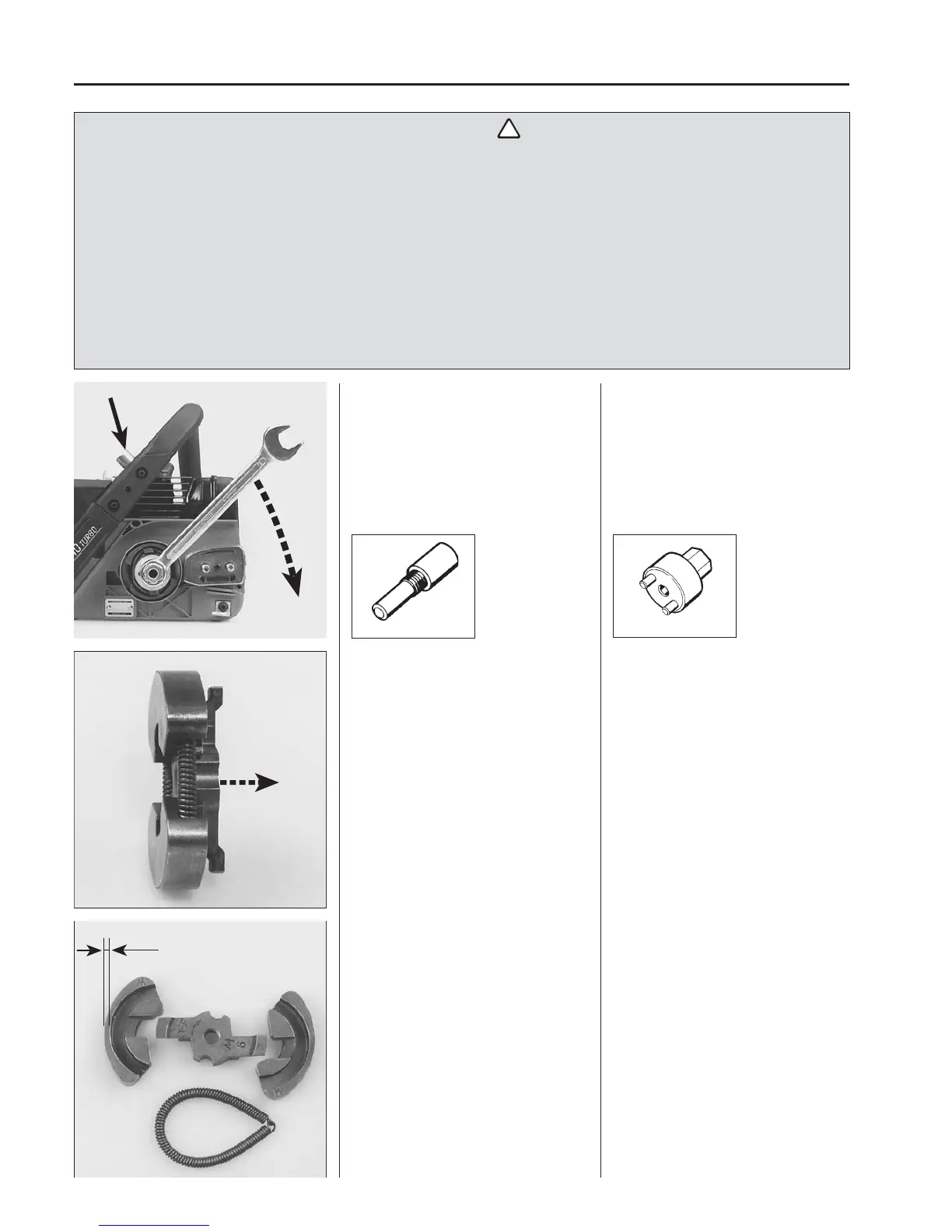

Press the clutch apart with your thumbs

Check the wear on the clutch.

The clutch shoes must have a thickness

of at least 1 mm at the most worn point.

Dismantling mod. 2036/2040

Remove the clutch cover, chain and bar.

Fit piston stop No. 502 50 33-01 in the

plug hole.

Use tool 530 03 11-12 and unscrew the

clutch from the crankshaft.

Press out the clutch centre from the back

of the clutch with your thumbs.

Clean and inspect the different parts for

wear.

The clutch shoes must have a thickness

of at least 1 mm at the most worn point.

If they are more worn than this the

complete clutch must be replaced.

Loading...

Loading...